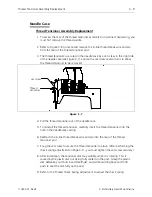

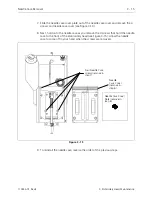

To position the solenoid and bracket:

1. Put the new solenoid and bracket assembly in place and push it to the back of

the cutout in the side of the head.

2. Attach it to the head with the 2 screws removed earlier, then check the

alignment to be within the above 3 positions. Be sure that the plunger contacts

the reciprocator mechanism, that the mechanism works properly, and that the

jump stitch assembly does not contact the embroidery head connecting rod

during its mechanical motion.

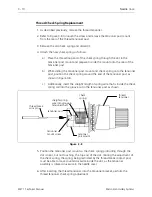

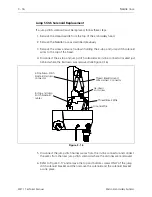

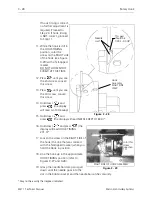

3. Reattach the e-stop and jump stitch solenoid in-line connector at the top of the

head and again secure the wires with the tie-down and screw.

4. Reinstall the needle case and all the covers removed to change the jump stitch

solenoid and test embroider a large letter (6 inch block I, for example) to check

the machine for proper jump stitch operation.

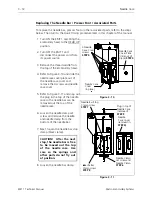

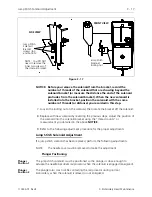

After attaching the new solenoid and bracket assembly to the embroidery head and

check the alignment. Be sure the plunger contacts the reciprocator mechanism, and

the reciprocator mechanism does not contact other internal head parts when the

solenoid is energized. The two wires coming from the solenoid and connecting at

the small black plastic connector, can be damaged if they are twisted together.

Twisting the wires together will reduce their length and can put undue stress at the

connections at both ends. It therefore is not recommend twisting these wires

together. If you must group these wires together, use "cable ties" (plastic straps)

these are available at most electronic supply stores.

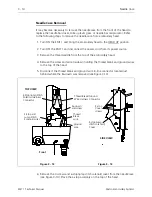

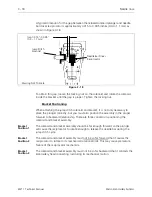

Jump Stitch Solenoid Adjustment

3 - 19

110344-01, Rev B

3. Embroidery Head Maintenance