Maintenance

4-1

4. Operator Maintenance

This chapter outlines machine maintenance; in addition, operators and maintenance personnel

must attend a Melco approved training course prior to maintaining the machine.

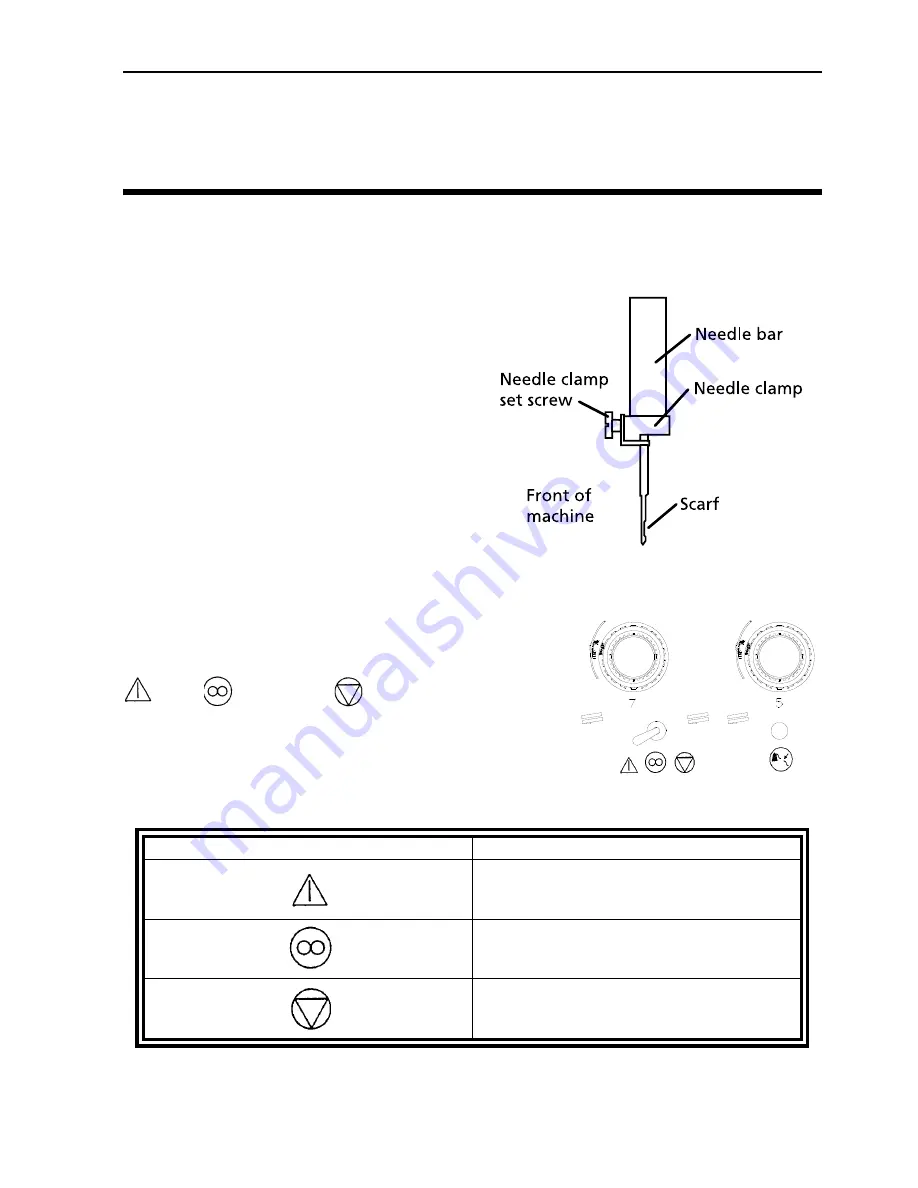

Installing a Needle

Each needle has a needle clamp set screw hold-

ing it in place as shown in Figure 4-1. Use the

small flat-blade screw driver from the tool kit

and follow these steps to replace a needle:

1. Turn the set screw counterclockwise until

the needle can slide down and out of the

needle bar. Do not remove the set screw.

2. With the scarf of the new needle toward

the rear of the head, slide the needle into

the needle bar as far as it will go, and re-

tighten the set screw. The eye of the needle

should be facing directly forward.

Thread Break Switch

Each head has a thread break switch below the tensioners with

(ON),

(AUTO), and

(OFF) positions (see Figure

4-2). The switch controls whether the individual head stitches as

it moves through a design. The table below summarizes the

functions of the switch.

11817 Rev. A

4. Operator Maintenance

Figure 4-1

Figure 4-2

SETTING

FUNCTION

Sews during thread break and framing

recovery. Use to restitch an area.

Only heads with thread breaks will sew

during thread break recovery or framing.

Should be used for normal operation.

Disables the sewing head.

Summary of Contents for EMT 10/4

Page 52: ...2 28 Quick Start Operation Manual for the EMT 10T 10 4 and 10 4T Melco Embroidery Systems ...

Page 108: ...6 10 Error Messages Operation Manual for the EMT 10T 10 4 and 10 4T Melco Embroidery Systems ...

Page 126: ...INDEX Operation Manual for the EMT 10T 10 4 and 10 4T ...

Page 127: ...Quick Ref erence Guide for the EMT 10T 10 4 and 10 4T 11817 Revision A ...