GENERAL

CS1000 single pole plugs and connectors are de-

signed with safety and durability in mind. A finger

guard on the receptacle provides IP2X protection

from live parts. A locking pin prevents unwanted dis-

connection. Each of the phases as well as the neutral

and ground are color coded and keyed to prevent

improper connection. Please follow the instructions

below to ensure the proper installation and use of the

product.

There are inherent dangers

associated with electrical prod-

ucts. Failure to follow safety precautions can result

in serious injury or death. These instructions must be

followed to ensure the safe and proper installation,

operation and maintenance of the MELTRIC devices.

Before installation, disconnect all sources of power to

the circuit to eliminate the risk of electrical shock.

RATINGS

CS1000 plugs and receptacles are UL and CSA

listed in accordance with UL 1691 and CSA 1691-12.

CS1000 devices are for use in Non-Load Break

applications up to 400A at 600VAC, 600VDC (in

North America) or 1000VAC, 1500VDC (in Europe –

CE rated).

The CS1000 devices are NOT designed or

listed for current interruption.

Risk of Electric Shock. Do

Not Disconnect Under Load.

INSTALLATION

These products should be installed by qualified

personnel in accordance with all applicable local

and national electrical codes.

Before starting, verify that the power is off, that the

product ratings are appropriate for the application,

and that the conductors meet code requirements and

are within the capacities of the lugs noted in Table 1.

NOTICE:

Connect only copper or copper-clad wire to

this device.

NOTICE:

For correct operation, the power cable

must not exert significant force on the product.

Wiring of the main conductor

Strip the conductor by approximately 1-1/8" depending

on the lug used. Lugs to be crimped with Greenlee

EK6IDL11 Crimping Tool, Dieless 120V CHRG.

Tighten small (through 45-3A12D) Straight Threaded

Lugs (Type D) with a 21 mm wrench and large

(45-3A18D and up) with a 24 mm wrench. Tighten

Straight With Terminal Lug (Type C) screw and

washer with a 19 mm socket.

The tightening torque must not be transmitted

to the insulated casing. To avoid transmitting

torque to the device when securing the lugs, hold the

terminal in place with a 20 mm wrench.

Torque both Type C and Type D style lugs to 30 ft-lb.

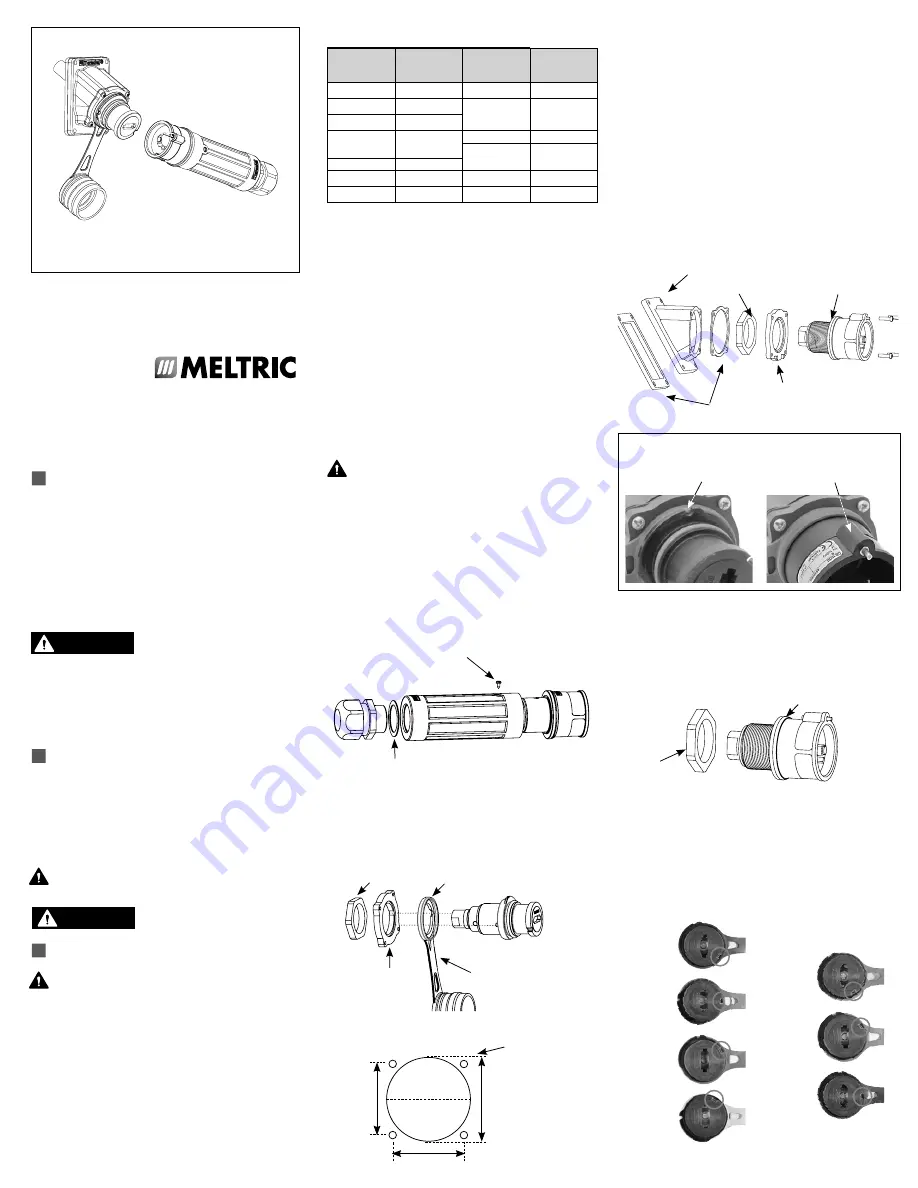

Assembly of the handle

Screw handle onto the product and tighten the cable

gland with an appropriate tool. Block the rotation of

the handle with the supplied screw. Assemble as

shown below.

Assembly with adapter plate

Assemble the adaptor plate on the product and

tighten the M40 nut with an appropriate tool.

Align tabs and assemble as shown below.

Hole pattern for adapter plate

NOTICE:

In order to maintain IP66/67 protection in

custom installations, watertight seals must be used

under the heads of the four mounting fasteners and

they must be retained by a lock washer and nut on

the inside of the box or panel. Alternatively, four blind

holes can be drilled and threaded to accommodate

#8-32 x 5/8" mounting screws. The hole depth must

be sufficient to achieve adequate gasket compres-

sion.

Assembly on an inclined sleeve

(with adapter plate)

Assemble the adapter plate on the inclined sleeve.

Do not forget the gasket between the adaptor plate

and the inclined sleeve, and between the inclined

sleeve and the panel. Assemble as shown below.

When mounting on a wall or panel, position the inlet or

receptacle so that the locking pin or latch is at the top.

Assembly on a panel board

Direct assembly

Assemble the product on the panel board and tighten

the M40 nut supplied, with an appropriate tool.The

watertightness is achieved by the color-coded ring.

Color coded ring and color-coded ring for the lid

In order to achieve watertightness, do not forget the

color-coded ring at the rear of the inlet or receptacle

and the panel.

5 Mechanical Keying Postions

(North America color codes shown.)

M40 nut

Color-coded ring

Adapter

plate

Cap (partial

view)

M40 nut

Cap with Color-coded ring

Adapter plate

Inclined sleeve

M40 nut

Watertightness gaskets

Color-coded ring

1.89"

.19Ø mount

holes

2.25"

1.89"

WARNING

DANGER

CAUTION

NOTICE

ADVERTENCIA

DANGER

CAUTION

AVISO

WARNING

DANGER

CAUTION

NOTICE

ADVERTENCIA

DANGER

CAUTION

AVISO

WARNING

DANGER

CAUTION

NOTICE

ADVERTENCIA

DANGER

CAUTION

AVISO

Locking latch

Locking pin

L1

L2

L3

Neutral

Ground

Positive

Negative

Table 1 CS1000 Crimping Lugs

1

Conductor

Size

2

Allowable

Current (A)

3

Straight With

Terminal

Straight

Threaded

1/0

4

200

45-3A50C

45-3A50D

2/0

250

45-3A70C

45-3A70D

3/0

275

4/0

300

45-3A95C

45-3A95D

45-3A12C

45-3A12D

250

325

350

350

45-4A18C

45-4A18D

450

5

400

45-4A24C

45-4A24D

1. Lugs to be crimped with Greenlee EK6IDL11 Crimping Tool,

Dieless 120V CHRG.

2. Type W or Compact Cable.

3. Intended to be wired with conductors rated 90°C or higher.

4. The ground conductor for the CS1000 series devices shall be

limited to a maximum size of 1/0 AWG.

5. 444 Locomotive or Diesel Cable to 500MCM Compact Cable.

WARNING

DANGER

CAUTION

NOTICE

ADVERTENCIA

DANGER

CAUTION

AVISO

Screw to block rotation

Watertightness gasket

WARNING

DANGER

CAUTION

NOTICE

ADVERTENCIA

DANGER

CAUTION

AVISO

CS1000

ENGLISH OPERATING INSTRUCTIONS

A COMPANY OF MARECHAL ELECTRIC

MELTRIC Corporation / 4765 W. Oakwood Park Drive Franklin, WI 53132

Tel. : 800 433 7642 / Fax : 414 433 2701 / e-mail : mail@meltric.com

INSCS1000 G

A manufacturer of products using

MARECHAL® TECHNOLOGY

meltric

.com

©2018 MELTRIC Corporation. All rights reserved.