Assembly for Mounted Receptacles

(or Inlets)

In applications where DXN receptacles (or inlets) are

mounted to wall boxes, panels or other equipment,

optimal operation is achieved when the

device is installed with the pawl/latch at the top.

NOTICE:

If the device is mounted to a wall box, make

sure that appropriate hole plugs are securely tightened

in any unused connection holes.

Insert the cable or wires through the wall box and

cut

to allow adequate length, strip the cable sheath,

as desired, strip the individual wires to the lengths

indicated in Table 3, and twist the strands of each

conductor together. Back out the terminal screws on

the receptacle (or inlet) far enough (but not completely)

to allow the conductors to pass, insert the conductors

fully into their respective terminals and tighten the

terminal screws to the torque indicated in Table 4, with

a hand screwdriver.

Assemble the receptacle (or inlet) and the color-coded

gasket to the box with appropriate hardware.

NOTICE:

Over-tightening the screws may cause cracking

in polymeric components. Assemble the mating plug

(or receptacle) to the cord end as indicated in the

assembly instructions above for in-line connections,

except there will be no finger drawplate or associated

black gasket.

In cases where custom mounting is being performed

to an appropriate hazardous duty box or panel, the

clearance and mounting holes should be drilled as

indicated in the following diagram.

Hole Pattern for Custom Mounting

NOTICE:

In order to maintain IP66/IP67 protection

in custom installations, watertight seals must be used

under the heads of the four mounting bolts and they

must be retained by a lock washer and nut on the inside

of the box or panel. Alternatively, four blind holes can

be drilled and threaded to accommodate #8-32 x 5/8"

mounting screws. The hole depth must be sufficient to

achieve adequate gasket compression.

OPERATION

To ensure safe and reliable operation,

MELTRIC plugs and receptacles must be used

in accordance with their assigned ratings.

They can only be used in conjunction with mating

receptacles or plugs manufactured by MELTRIC or

another licensed producer of products bearing the

technology trademark.

MELTRIC plugs & receptacles are designed with

different keying arrangements, so that only plugs

and receptacles with compatible contact configura-

tions and electrical ratings will mate with each other.

Connection

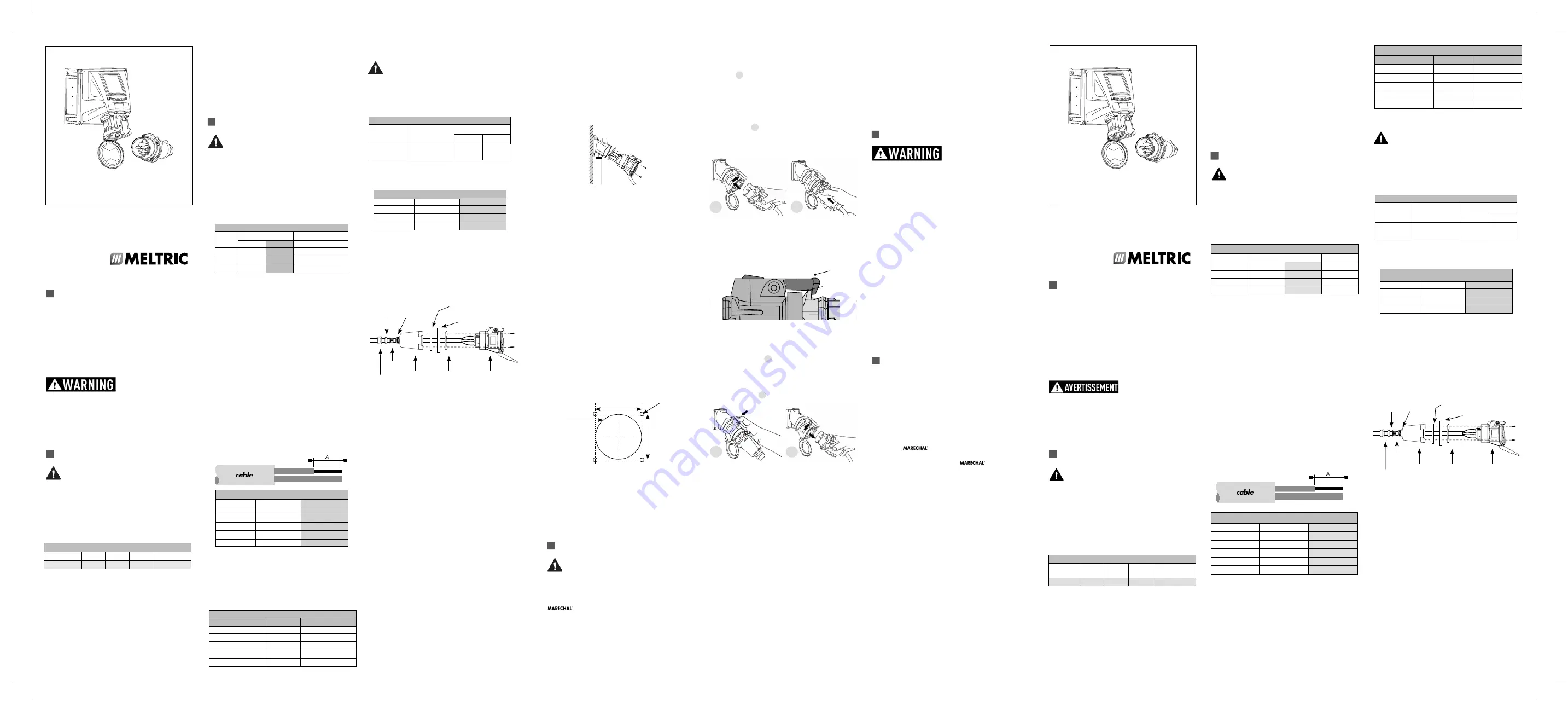

To connect a plug and receptacle, first depress the

pawl to open the lid on the receptacle, then orient

the plug 1. so that the red arrow on the outside of

the casing lines up with the red arrow just to the left

of the latch on the receptacle casing. Push the plug

partially into the receptacle until it hits a stop, then

rotate the plug in the clockwise direction until it hits

another stop after about 30° of rotation. At this point,

the circuit is still open. Push the plug straight into

the receptacle 2. until it becomes securely latched in

place. The connection is now made. For in-line connectors,

squeeze the drawplates on both sides of the device

together until the plug latches in place.

NOTICE:

When making a connection, ensure that

the plug latch is secured behind the catch on the blue

pawl. A properly connected plug cannot be pulled out

of the receptacle.

Disconnection

To break the connection, simply depress the pawl

as shown in figure 3. This will break the circuit and

eject the plug straight out to the rest, or off, position.

The plug contacts are de-energized at this point. To

remove the plug, rotate it counterclockwise (CCW)

(about 30°) until it releases from the receptacle as

shown in figure 4. Close and latch the lid on the

receptacle.

Achieving Watertightness Ratings

DXN’s have an IP66/IP67 rating for protection against

ingress of water, dust and other matter. IP66 provides

total protection against dust and water jets. IP67 adds

protection for temporary immersion in shallow water.

These ratings apply when the plug and receptacle

are mated. They also apply to the receptacle alone,

provided that its lid is latched in the closed position.

Optional plug caps are available for providing IP66/

IP67 protection on unmated plugs.

NOTICE:

MELTRIC threaded handles come with

tapered style threads.The use of fitting seal tape is

recommended to maintain watertightness of all NPT

fittings and joints.

Lockout Provisions

All DXN plugs are provided with lockout provisions. To

lockout the plug, insert the locking device through the

hole provided in the casing. This will prevent the plug

from being able to be inserted into a receptacle.

Receptacles can be purchased with optional lockout

provisions. MELTRIC’s Locking Pin must be used to

lockout the receptacle. Close and latch the lid. Slide

MELTRIC’s Locking Pin through the hole provided in

the latch and place a padlock or other locking device

through one of the holes on the locking pin. This will

prevent the lid from being opened.

NOTICE:

Attaching the receptacle locking device with

the lid open will not prevent the insertion of a plug.

Lockout is only accomplished when the lid is locked

closed.

MAINTENANCE

Before inspecting, repairing,

or maintaining MELTRIC

products, disconnect electrical power to the receptacle to

eliminate the risk of electrical shock. Any replacement of

DXN components must be performed under the control of

the manufacturer: MELTRIC Corporation.

MELTRIC products require little on-going maintenance.

However, it is a good practice to periodically perform

the following general inspections:

• Check the mounting screws for tightness.

• Verify that the weight of the cable is supported

by the strain relief mechanism and not by the

terminal connections.

• Check the IP gaskets for wear and resiliency.

Replace as required.

• Verify the electrical continuity of the ground circuit.

•

Check the contact surfaces for cleanliness

and pitting.

Deposits of dust or similar foreign materials can be

rubbed off the male contacts with a clean cloth. Sprays

should not be used, as they tend to collect dirt. If

any significant pitting of the contacts or other serious

damage is observed, the device should be replaced.

Risk of electrostatic discharge: use a cloth slightly

soaked in soapy water for cleaning

MANUFACTURER’S RESPONSIBILITY

MELTRIC’s responsibility is strictly limited to the repair

or replacement of any product that does not conform

to the warranty specified in the purchase contract.

MELTRIC shall not be liable for any penalties or

consequential damages associated with the loss of

production, work, profit, or any other kind of financial loss

incurred by the customer.

MELTRIC Corporation shall not be held liable when

its products are used in conjunction with products not

bearing the

technology trademark. The use of

MELTRIC products in conjunction with mating devices

that are not marked with the

technology

trademark shall void all warranties on the product.

MELTRIC Corporation is an ISO 9001 certified company.

Its products are designed, manufactured and rated in

accordance with applicable UL, CSA and IEC standards.

MELTRIC designs and manufactures its products in

accordance with Marechal keying standards established

to ensure intermatablility with similarly rated products

manufactured by Marechal Electric Group.

DXN20: 1.656"

(

42mm

)

DXN30: 1.890"

(

48mm

)

DXN60: 2.171"

(

55.2mm

)

DXN20: 2.00"

(

51mm

)

DXN30: 2.25"

(

56mm

)

DXN60: 2.72"

(

69mm

)

DXN20: 1.656" (

42 mm

)

DXN30: 1.890" (

48 mm

)

DXN60: 2.171" (

55.2 mm

)

4 x Ø.196

(

#9 or 5mm

)

INSDXN N

3

4

GENERAL

MELTRIC’s DXN Series plugs & receptacles are

designed and rated for use in hazardous environments

where explosive gases or dusts may be present.

The DXN receptacle has a dead front, which isolates

the supply contacts and prevents user exposure to live

parts. The receptacle’s safety shutter blocks access to

the contacts and can only be opened by DXN plugs

with compatible ratings and contact configurations.

There are inherent dangers

associated with electrical

products. Failure to follow safety precautions can result in

serious injury or death. These instructions must be

followed to ensure the safe and proper installation,

operation and maintenance of the MELTRIC devices.

Before installation, disconnect all sources of power to

the circuit to eliminate the risk of electrical shock.

RATINGS & CERTIFICATIONS

To ensure the safe use of this product, the

installer must verify that the product is properly

rated for the application.

The amperage and voltage ratings are indicated on

the device labels. Some DXN devices are provided

with optional auxiliary contacts that make after and

break before the phase contacts. The ratings for

auxiliary contacts are shown in Table 1.

Hazardous Duty Ratings

DXN plugs & receptacles have both ATEX and CSA

ratings for use in hazardous environments.

ATEX – Class 1 Zone 1 AEx ed IIC T6

This rating certifies the product for use in surface

(non-underground) applications where a high level

of protection is required and where the presence of

an explosive atmosphere of any type of gas or dust

is likely to occur. The associated maximum surface

temperature of the product is 85°C (185°F), at an

ambient temperature of 40°C (104°F).

CSA –

Class 1 Division 2 Group A, B, C, D

Class 2 Division 2 Group E, F, G

This rating certifies the product for use in applications

where flammable gases, such as acetylene, hydrogen,

ethylene or propane, or dusts, such as magnesium,

coal or grain, may be present under abnormal conditions.

INSTALLATION

DXN’s must be used in conjunction with other

appropriately rated hazardous duty products

and must be installed by qualified electricians in

accordance with all applicable local and national

electrical codes.

Before starting, ensure that the power is off and verify

that the conductors meet the requirements of the

National Electric Code and are within the capacities of

the DXN terminals noted in Table 2.

1

Capacity is based on certification testing. Wire size

should be determined in accordance with the electrical code.

2

Auxiliary contacts are optional

General Notes & Precautions

1. Self-tapping screws are provided for use with

some polymeric accessories. High torque may

be required to drive them in and fully seat

the gasket/s. Once they are seated, care

should be taken in order to avoid over-tight-

ening them against the poly material.

Poly Box with 70° Poly Angle accessory:

captive screws must be tightened to a torque of

1.2Nm (10.62 in-lbs)

Metal Box with 70° Poly Angle accessory:

captive screws must be tightened to a torque

of 2.0Nm (17.7 in-lbs)

2.

Wire strip lengths are indicated in Table 3.

Strip lengths for cable sheathing will depend

on the specific application. When used with

handles, the cable sheathing should extend

into the handle to ensure secure cord gripping.

3. Wiring terminals are spring assisted to prevent

loosening due to wire strand settlement, vibration

& thermal cycling. They should not be over-tightened.

Appropriate tools and tightening torques are indicated

in Table 4.

NOTICE:

Do not back terminal screws

completely out.

Assembly for In-line Plugs/Connectors

Do not overtighten terminal or self-tapping

screws. Tighten screws to the proper torque to

ensure a secure connection.

Flexible cord connected devices must be equipped with

a flexible cord listed for extra hard usage and terminated

with listed fittings in accordance with all applicable

local and national electrical codes. See table 6.

DXN devices are rated to make and withstand short

circuit currents with appropriate fusing as indicated

in Table 5.

When DXN’s are used as in-line connectors,

finger

drawplates should be installed on both the receptacle

and plug in order to more easily provide the leverage

required to properly connect the devices.

Loosely re-assemble the compression nut, bushing and

strain relief to the threaded adapter on the end of the

handle and insert the cable through it, the thin black

drawplate gasket and finger drawplate (if applicable),

and the color-coded gasket. Being mindful that the

strain relief must clamp on the cable sheath, strip the

cable sheath as required to provide a workable wire

length. Then strip the individual wires to the lengths

indicated in Table 3, and twist the strands of each

conductor together.

NOTICE:

Back out the terminal screws on the receptacle

(or inlet) only far enough to allow the conductors to

pass, insert the conductors fully into their respective

terminals and tighten the terminal screws with a hand

screwdriver to the torque indicated in Table 4.

Verify that the cable jacket will extend beyond the

strain relief and into the handle. Assemble the

receptacle (or inlet), the color-coded gasket, the

finger drawplate, and the thin black finger drawplate

gasket to the handle with the four self-tapping screws

provided.

NOTICE

: Over-tightening the screws may

cause cracking in polymeric components. Adjust the

cable location so that it will not be under tension inside

the handle and tighten the compression nut to secure

the cable.

Short Circuit MELTRIC’s DXN Series Plugs &

Receptacles have short circuits make (close) and

withstand ratings up to 25kA when used with the

fusing shown in Table 5.

Compression

Nut

Handle

Strain

Relief

Color-Coded

Gasket

Receptacle

(or Inlet)

Bushing

Threaded

Adapter

Finger Drawplate Gasket

DXN20 Remove Adhesive Liner

Finger Drawplate

DXN20

7.1 in-lbs

1/8" precision tip

DXN30

(Main Contacts)

10.6 in-lbs

3/16" precision tip

DXN30

(Aux. Contacts)

7.1 in-lbs

1/8" precision tip

DXN60

(Main Contacts)

17.7 in-lbs

3/16" precision tip

DXN60

(Aux. Contacts)

7.1 in-lbs

1/8" precision tip

Table 4 - Recommended Tightening Torques

Terminal

Torque Flat Screwdriver

Inches

mm

DXN20 - Main

0.50/0.50 12/12

DXN30 - Main

0.79/0.83 20/21

DXN30 - Aux.

0.67/0.67 17/17

DXN60 - Main

0.79/0.83 20/21

DXN60 - Aux

0.67/0.83 17/21

Table 3 - Wire Strip Length - A (receptacle/inlet)

Max Min

Max

DXN20

10

16

N/A

DXN30

6

14

10

DXN60

4

10

10

Table 2 - Wiring Terminal Capacity

1

- AWG

Main Contacts

Aux. Contacts

2

Table 1 - Auxiliary Contact Ratings

Device 120VAC 240VAC 480VAC 600VAC

DXN30,60 5A* 5A* 5A*

5A* (550V max)

Extra Hard

5

0.812 0.312

Usage

Table 6 - Flexible Cord

Type

Max Nos of

Flexible Cable Range

Conductors

Max Øin

Min Øin

Device

Rating Fuse

Type*

DXN20 - 20A

25 kA@600VAC

RK1

30A

DXN30 - 30A

25 kA@600VAC

RK1

70A

DXN60 - 60A

25 kA@600VAC

RK1

100A

Table 5 - Short Circuit Make & Withstand Ratings

* DXN20, 30 Ratings are based on testing with Mersen

Non-Time delay current limiting fuses

DXN60 Ratings are based on testing with Little Fuse

Non-Time delay current limiting fuses

* Note: Consult NEC for short circuit limits

INSDXN N

A COMPANY OF MARECHAL ELECTRIC

MELTRIC Corporation / 4765 W. Oakwood Park Drive Franklin, WI 53132

Tel. : 800 433 7642 / Fax : 414 433 2701 / e-mail : mail

@

MELTRIC.com

A manufacturer of products using Marechal technology

MELTRIC

.com

©2019 MELTRIC Corporation. All rights reserved.

DX

CONSIGNES D’UTILISATION

DXN SERIES

ENGLISH OPERATING INSTRUCTIONS

RENSEIGNEMENTS GÉNÉRAUX

Les fiches et prises de la série DXN de MELTRIC sont

conçues et homologuées pour les environnements

dangereux qui comprennent des poussières ou des

gaz explosifs.

La prise DXN est équipée d'un écran isolant qui

couvre les contacts et empêche l'exposition aux

pièces sous tension. Le mécanisme d'obturation de

la prise bloque l'accès aux contacts et ne peut être

ouvert qu'en insérant une fiche DXN dont les calibres

et la configuration sont compatibles.

Il existe des dangers

inhérents aux produits

électriques. Le non-respect des règles de sécurité

peut entraîner des blessures graves ou la mort. Les

présentes instructions doivent être suivies pour

assurer une installation, une utilisation et un entretien

adéquats et sécuritaires. Avant l'installation,

débranchez toute source d'alimentation du circuit afin

d'éliminer les risques d'électrocution.

CALIBRES ET HOMOLOGATIONS

Pour utiliser ce produit de façon sécuritaire,

l'installateur doit s'assurer que le calibre

convient à l'utilisation prévue.

L'intensité et la tension nominales sont indiquées sur

les étiquettes de l'appareil. Certains appareils DXN

sont équipés de contacts auxiliaires optionnels qui

se connectent après les contacts de phase, mais qui

se déconnectent avant ces derniers. Les calibres des

contacts auxiliaires sont indiqués dans le tableau 1.

Homologations pour environnements dangereux

Les fiches et prises DXN sont conformes à la

réglementation ATEX et homologuées par la CSA

pour les environnements dangereux.

ATEX – Classe 1, Zone 1, AEx ed IIC T6

Cette classification certifie que le produit convient aux

utilisations au niveau du sol (non souterraines) qui

exigent beaucoup de protection et où l'atmos-phère

peut être explosive en raison de la présence d'un

gaz ou de poussières. La température max-imale à

la surface de l'appareil est de 85 °C (185 °F), à une

température ambiante de 40 °C (104 °F).

CSA – Classe 1, Division 2, Groupe, A, B, C, D

Classe 2, Division 2, Groupe E, F, G

Cette classification certifie que le produit convient

aux utilisations pour lesquelles, dans des conditions

anormales, des gaz inflammables (comme l'acétylène,

l'hydrogène ou le propane) ou des poussières

inflammables (comme la poussière de magnésium

ou de charbon ou la poussière céréalière) peuvent

être présents.

INSTALLATION

Les appareils DXN doivent être utilisés avec

du matériel de calibre approprié et doivent être

installés par des électriciens qualifiés, dans le respect

des normes locales et nationales sur l'électricité.

Avant de commencer, assurez-vous que l'alimentation

est coupée, que les conducteurs sont conformesau

National Electric Code

et que leurs capacités

correspondent aux valeurs indiquées dans le tableau 2

pour les bornes DXN.

1

Capacité indiquée pour des fils de type THHN.

2

Les contacts auxiliaires sont optionnels.

Remarques et précautions générales

1. Des vis autotaraudeuses sont fournies pour la

pose de certains accessoires en polymère. Un

torque élevé peut être requis pour les fixer

complètement dans le joint d’étanchéité, mais

prenez soin de ne pas trop les serrer sur le matériau.

Les boîtes en polyester avec angle de 70° en

polyester; les vis captives doivent être serrés

avec un torque de 1.2Nm (10.62 pouce-livre).

Les boîtes en métal avec angle de 70° en polyester;

les vis captives doivent être serrés avec un torque de

2.0Nm (17.7 pouce-livre)

2. Les longueurs de fil dénudé sont indiquées au

tableau. 3. La longueur de câble à dénuder

dépend de l'utilisation prévue. Pour fixer un câble

à une poignée, assurez-vous que la gaine du

câble dépasse à l'intérieur de la poignée pour que

le cordon offre une bonne prise.

3.

Les bornes de raccordement sont dotées de

ressorts pour empêcher la formation d'un jeu

causée par le déplacement des brins des câbles,

les vibrations et les cycles thermiques. Elles

ne doivent pas être trop serrées. Les outils et

couples de serrage appropriés sont indiqués

dans le tableau 4.

ATTENTION:

Ne dévissez pas

complètement les vis des bornes.

Assemblage pour prises ou connecteurs en série

Ne serrez pas trop les vis des bornes et les

vis autotaraudeuses. Serrez les vis au couple

approprié pour assurer une bonne connexion.

Les produits à raccord avec cordon flexible doivent

être utilisés avec un cordon flexible à usage intense et

munie d’accessoires de raccord selon les lois et normes

en vigueur localement et selon le code électrique. Voir

tableau 6.

Les produits de la série DXN sont fait pour supporter

et maintenir un courant de court-circuit selon les

spécifications du tableau 5 lorsque protégé par fusible.

Pour l'utilisation d'un appareil DXN comme connecteur

en série, il est préférable d'installer des plaques de

levage sur la prise et sur la fiche afin de faciliter les

branchements et débranchements.

Sans les serrer, remontez l'écrou de compression,

l'embout et le serre-câble sur l'adaptateur fileté à

l'extrémité de la poignée, puis faites passer le câble

dans l'adaptateur, dans la plaque de levage et son

mince joint d'étanchéité noir (si l'appareil en est

équipé), et dans le joint d'étanchéité à code de

couleur. En vous assurant que le serre-câble retient

bien la gaine du câble, dénudez le câble de sa gaine

de manière à obtenir une longueur suffisante pour

travailler. Dénudez ensuite chaque fil en respectant les

longueurs indiquées dans le tableau, puis entortillez

les brins de chaque conducteur.

ATTENTION :

Dévissez les vis des bornes de la

prise juste assez pour pouvoir passer les conducteurs,

enfoncez complètement les conducteurs dans leurs

bornes respectives et serrez les vis des bornes à l'aide

d'un tournevis, au couple de serrage indiqué dans le

tableau 4.

Assurez-vous que la gaine du câble dépasse

le niveau du serre-câble et pénètre dans la

poignée. Installez la prise, le joint d'étanchéité à

Tableau 4 – Couples de Serrage Recommandés

Borne

Couple

Tournevis Plat

DXN20

7,1 lb-po

pointe de 1/8 po

DXN30 (Contacts Princ.)

10,6 lb-po

pointe de 3/16 po

DXN30 (Contacts Aux.)

7,1 lb-po

pointe de 1/8 po

DXN60 (Contacts Princ.)

17,7 lb-po

pointe de 3/16 po

DXN60 (Contacts Aux.)

7,1 lb-po

pointe de 1/8 po

Écrou de

compression

Poignée

Serre-

câble

Joint à code

de couleur

Prise

Embout

Adaptateur

fileté

Joint d'étanchéité de la plaque de levage

DXN20 enlever l’auto-collant

Plaque de levage

WARNING

DANGER

CAUTION

NOTICE

WARNING

DANGER

CAUTION

NOTICE

WARNING

DANGER

CAUTION

NOTICE

Tableau 1 – Calibre des Contacts Auxiliaires

Appareil

120V

c.a.

240V

c.a.

480V

c.a.

600V c.a.

DXN30, 60

5A*

5A*

5A*

5A* (550V max)

Tableau 2 – Capacité des bornes

1

-- AWG

Contacts Princ.

Contacts

2

Max

Min

Max

DXN20

10

14

S.O.

DXN30

6

12

10

DXN60

4

10

10

Tableau 3 – Longueur à Dénuder -- A (prise)

Pouces

mm

DXN20 – Princ.

0,50/0,50

12/12

DXN30

– Princ.

0,79/0,83

20/21

DXN30

– Aux.

0,67/0,67

17/17

DXN60

– Princ.

0,79/0,83

20/21

DXN60

– Aux.

0,67/0,83

17/21

Usage

5

0.812 0.312

Intense

Tableau 6 – Cordon flexible

Tipo

Nbre de

Plage du câble

conducteur max

Max Øpouce Min Øpouce

Produit

Calibre du fusible

Type*

DXN20 - 20A

25 kA@600VAC

RK1

30A

DXN30 - 30A

25 kA@600VAC

RK1

70A

DXN60 - 60A

25 kA@600VAC

RK1

100A

Tableau 5 – Niveau de courant de court-circuit

supporté et maintenu

* Les niveaux pour DXN20, 30 sont basés sur les essais

fait avec des fusibles Mersen à action rapide limiteur

de courant.

Les niveaux pour DXN60 sont basés sur les essais fait

avec des fusibles Littelfuse à action rapide limiteur de

courant.

* Note: Consulter NEC pour les limites de court-circuit

INSDXN N

A COMPANY OF MARECHAL ELECTRIC

MELTRIC Corporation / 4765 W. Oakwood Park Drive Franklin, WI 53132

Tel. : 800 433 7642 / Fax : 414 433 2701 / e-mail : mail

@

MELTRIC.com

A manufacturer of products using Marechal technology

MELTRIC

.com

©2019 MELTRIC Corporation. All rights reserved.

DX

CONSIGNES D’UTILISATION

SERIE DXN

FRANÇAIS CONSIGNES D’UTILISATION

Pawl

Latch

Receptacle

Plug/Inlet

1

2

INSDXN_N.indd 1

INSDXN_N.indd 1

12/20/19 1:09 PM

12/20/19 1:09 PM