GENERAL

PN, DS and DSN Multipin products are used for power

and control. They can carry loads as well as low level

signals and information. These multipin devices comply

with applicable IEC standards.

Please follow the instructions below to ensure the proper

installation, operation and maintenance of this product.

There are inherent dangers

associated with electrical

products. Failure to follow safety precautions can result in

serious injury or death. These instructions must be followed

to ensure the safe and proper installation, operation and

maintenance of the MELTRIC devices. Before installation,

disconnect all sources of power to the circuit to eliminate

the risk of electrical shock.

INSTALLATION

PN, DS and DSN Multipins should be installed by

qualified electricians in accordance with all applicable

local and national electrical codes.

Before starting, verify that the power is off, that the product

ratings are appropriate for the application, and that the

conductors meet code requirements and are within the

capacities of the terminals noted in Table 1.

General Notes & Precautions

1. Self-tapping screws are provided for use with

some polymeric accessories. High torque may be

required to drive them in.

NOTICE:

Once they

are seated, care should be taken in order to avoid

over-tightening them against the plastic material.

2. Various handles and cord grip options may be

used. These instructions are based on handles

provided with integral multi-layer bushing cord grips.

3.

NOTICE:

MELTRIC threaded handles come with

tapered style threads. The use of fitting seal tape

is required to maintain watertightness of all

NPT fittings and joints.

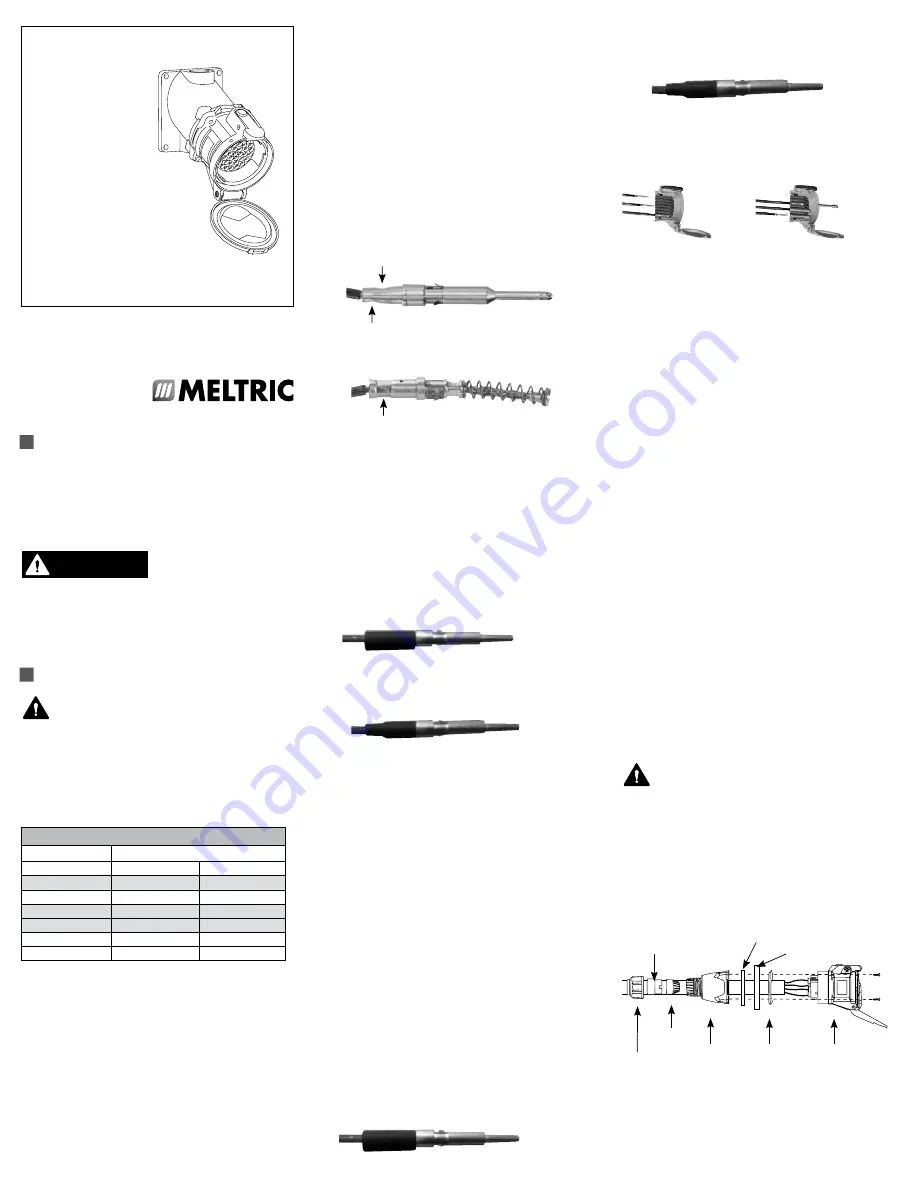

Crimped/Soldered Terminal Wire Connections:

For 18 AWG and 16 AWG wire, the use of ferrules is

required:

1. Strip each conductor to 25/64-inches (10-mm).

2. Insert ferrule into contact. For 16 AWG wire, use

ferrules marked MEC7177071. For 18 AWG wire

insert ferrule 22170-13 into ferrule MEC7177071.

3. Insert stripped wire end into ferrule.

(Perform either step 4 or 5)

4. For Crimping the Contacts, use either North

American Contact Crimping Tool 4CN30 (using

crimping slot 12-10) or Crimp contact with

European Contact Crimping Tool 61-CA500

(using 4 MM slot).

*With 4CN30 - Double crimp, once near the

terminal opening and a second crimp slightly

above the first, rotated 180 degrees.

*With 61-CA500 - Double crimp, once near the

terminal opening and a second time at the same

location, rotated 90 degrees.

5.

NOTICE:

Soldering of the wire into the contact

must be performed with the contact out

of the Interior Insulator to prevent damage

to the insulator.

• Using tin solder and a 50W soldering iron, heat

the terminal for approximately 30 seconds.

While heating, apply the soldering wire into the

hole at the bottom of the terminal and let it

penetrate by capillary action. Let it cool down

without any mechanical stress.

6. Slide the Heat Shrink Insulation Sleeve over the

contact until it butts up against the contact

shoulder.

NOTICE:

Sleeve must be applied to

maintain creepage and clearance distance.

Please see picture.

7. With a Heat Gun that has a temperature range

of 600°F to 950°F, apply heat evenly 360°

around the sleeve until it shrinks around the

contact and wire.

For 14 AWG Wires (Max), the Ferrule is not required:

1. Strip each conductor to 25/64-inches (10-mm).

2. Insert wire into contact.

(Perform either step 3 or 4)

3. For Crimping the Contacts, use either North

American Contact Crimping Tool 4CN30 (using

crimping slot 8) or Crimp contact with European

Contact Crimping Tool 61-CA500 (using 4 MM slot).

*With 4CN30 - Double crimp, once near the

terminal opening and a second crimp slightly

above the first, rotated 180 degrees.

*With 61-CA500 - Double crimp, once near the

terminal opening and a second time at the same

location, rotated 90 degrees.

4.

NOTICE:

Soldering of the wire into the contact,

must be performed with the contact out of the

Interior Insulator to prevent damage to the insulator.

• Using tin solder and a 50W soldering iron, heat

the terminal for approximately 30 seconds.

While heating, apply the soldering wire into the

hole at the bottom of the terminal and let it

penetrate by capillary action. Let it cool down

without any mechanical stress.

5. Slide the Heat Shrink Insulation Sleeve over the

contact until it butts up against the contact

shoulder.

NOTICE:

Sleeve must be applied to

maintain creepage and clearance distance.

Please see picture.

6. With a Heat Gun that has a temperature range

of 600°F to 950°F, apply heat evenly 360°

around the sleeve until it shrinks around the

contact and wire.

Assembly of Contacts

Once wired, the contacts must be inserted into the rear

of their respective insulating block. The rear side of the

inlet/plug or receptacle/connector is considered as the flat

surface of the 4-bolt hole mounting surface.

Assembly

Disassembly

1.

NOTICE:

Before insertion of a contact into an

insulator, please review the insulator’s contact

numbering scheme so the ground and each

contact (phase) is placed into the proper hole.

2. Push the wired contact into the insulating block

until it stops and snaps into place.

3. Ensure its correct mounting by slightly pulling on

the contact.

4. The male contacts are solid for their entire

length and are inserted with the contact tip first

into the rear of the inlet/plug.

5. The female contacts consist of a flexible braid

and spring and are inserted with the contact tip

first into the rear of the lidded receptacle/connector.

6. Insert the Provided Hole Plugs into the unused

holes in the front of each insulating block.

NOTICE:

If a new Receptacle or Inlet is to mate

with a previously installed device, pay particular

attention to the number of contacts and numbered

position in the Receptacle or Inlet. Continuity will not

be obtained unless the male and female contacts are

appropriately mated.

Disassembly of Contacts

1. To remove the contact from the insulating block,

the provided Multi-Contact Removal Tool 61-CA593

must be used. From the front side of the insulating

block, slide the contact removal tool over the contact.

2. Push until the contact pops out the back side of

the insulating block.

3.

NOTICE:

Each contact is designed to be

removed from the insulating block a maximum

of 3 times. New contacts should be used if

contacts are removed more than 3 times.

Voltage Labels

Always have a qualified electrician complete the

installation and apply one of the supplied voltage

labels that best describe the voltage application level.

WARNING:

For safety reasons, it is always recommended

to use a ground wire. Please reference

your local codes for specific electrical requirements.

Assembly for In-Line Connections (DS/DSN)

When DS and DSN Multipins are used as in-line connectors,

finger drawplates should be installed on both the receptacle

and plug in order for the user to more easily provide the

leverage required to connect the device.

Assembly for In-Line Connections (All)

Adjust the bushing diameter to fit the cable by removing

inner sections of it as required. Insert the bushing into the

strain relief, then insert the assembly into the handle

A COMPANY OF MARECHAL ELECTRIC

INSPNDSDSNMULTI A

A manufacturer of products using Marechal technology

Compression

Nut

Handle

Strain

Relief

Color-Coded

Gasket

Receptacle

(or Inlet)

Bushing

Finger Drawplate Gasket

Finger Drawplate

WARNING

DANGER

CAUTION

NOTICE

ADVERTENCIA

DANGER

CAUTION

AVISO

WARNING

DANGER

CAUTION

NOTICE

WARNING

DANGER

CAUTION

NOTICE

ENGLISH OPERATING INSTRUCTIONS

©2020 MELTRIC Corporation. All rights reserved.

Table 1 - Wiring Terminal Capacity

1

(in AWG)

Main Contacts

Device

Minimum

Maximum

PN12c

18

14

DSN12c

18

14

DSN24c

18

14

DSN37c

18

14

DS24c

18

14

DS37c

18

14

1

Capacity is based on THHN wire sizes

PN12c/DSN12c

DS24c/DSN24c

DS37c/DSN37c