GENERAL

SP devices are single-pole, high-amperage plugs and

receptacles that are designed for safety, durability,

and ease of operation. Each device is mechanically

interlocked with an integral pilot circuit switch for

controlling the power circuit in order to prevent

connection and disconnection under load. Each of

the phases as well as the neutral and ground, are

color coded and keyed to prevent improper connection.

SP receptacles are IP 2X rated to prevent accidental

finger contact with live parts.

There are inherent dangers

associated with electrical

products. Failure to follow

safety precautions can result in serious injury or death.

These instructions must be followed to ensure the safe

and proper installation, operation and maintenance of

the MELTRIC devices. Before installation, disconnect

all sources of power to the circuit to eliminate the risk

of electrical shock. This product must be installed with

an electrical interlock that prevents connection or

disconnection in a loaded condition.

RATINGS

The SP series is CSA listed for use in Non-Load Break

applications up to 600A at 600VAC, 500 HP 3 phase

at 480 VAC and 600 VAC. The SP devices are

NOT designed or listed for current interruption. The

SP receptacle is provided with two auxiliary/pilot

contacts that make (close) when the locking collar

is rotated after plug insertion. The pilot contacts are

designed for use in control circuit wiring of medium

current switchgear, (see diagram of pilot circuit wiring).

The SP pilots have a D300 rating as shown in Table 1.

The phase contact is rated to withstand a 30 kA short

circuit with a current limiting fuse rating as shown in

Table 2. Consult MELTRIC Engineering for horsepow-

er ratings and limitations at lower voltages.

INSTALLATION

SP devices should be installed by qualified

electricians in accordance with all applicable

local and national electrical codes.

Before installing, verify the power is off and the prod-

uct ratings are appropriate for the application. Ensure

the conductors meet code requirements and are with-

in the wiring terminal capacities noted in Table 3.

NOTICE:

Ensure the plug and its flexible cable do

not exert a significant force or a constraint on the

receptacle.

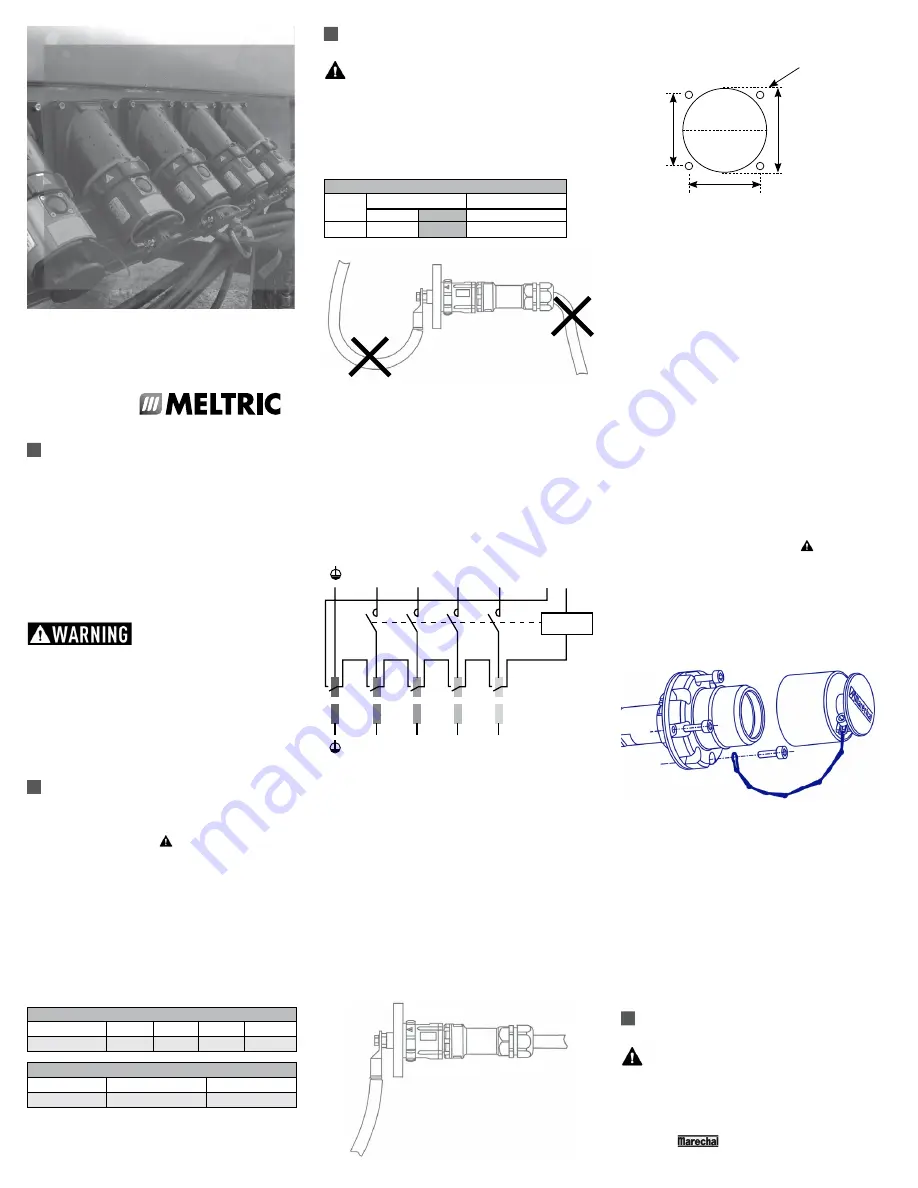

Wiring of the pilot contacts

The SP auxiliary/pilot contact leads of each device

should be wired in series within the power control

circuit. A typical pilot circuit wiring diagram is

shown below.

Wiring of the main conductor

Use a flexible cable between 2/0 and 777 MCM (70

and 400 mm

2

). Strip the insulation as appropriate for

the lug being used. Solder lugs have integral threads

that screw into the terminals. The solder lug should

be tightened until the tapered section is secured in

solid contact with the terminal. Crimped lugs are

secured with M12 bolts that should be tightened to

approximately 30 ft-lb (40 N.m.) with a 3/4" (19 mm)

wrench.

NOTICE:

To avoid transmitting torque to the device

moldings when securing the lugs, hold the terminal in

place with a 24 mm wrench (flats are provided).

Hole Pattern for Custom Mounting

NOTICE:

In order to maintain IP66/67 protection in

custom installations, watertight seals must be used

under the heads of the four mounting bolts and they

must be retained by a lock washer and nut on the

inside of the box or panel. Alternatively, four blind

holes can be drilled and threaded to accommodate

#8-32 x 5/8" mounting screws. The hole depth must

be sufficient to achieve adequate gasket compression.

Attaching the handle

Insert cable through cable gland and handle before

tightening the phase conductor. Assemble handle

with the screws and gasket supplied, (use short

screws for inlets, long screws for receptacles) and

tighten cable gland with an appropriate tool.

NOTICE:

MELTRIC solder lugs are required for use

with handles.

Attaching the metal angle (if required)

Attach receptacle or inlet to metal angle using the

screws and gasket supplied, (use short screws for

inlets, long screws for receptacles). Connect the

metal angle to ground.

Assembly of the plug/inlet cap

Attach the cap to the plug/inlet by retaining the end

of the chain under one of the mounting screws.

Gasket

In order to achieve rated watertightness, the flat

black gasket must be installed between the inlet or

receptacle and the panel or accessory to which it

is attached.

Rated current and voltage markings

It is essential to indicate the current and voltage of

the main circuit on the supplied stickers. Apply the

stickers on or adjacent to the product so they can

easily be seen.

OPERATION

To ensure safe and reliable operation,

MELTRIC plugs and receptacles must be used

in accordance with their assigned ratings.

SP devices can only be used in conjunction with

mating receptacles or plugs manufactured by

MELTRIC or another licensed producer of products

bearing the

™

technology trademark.

L1

L2

L3

N

L1

L2

L3

N

P1

P2

L1

L2

L3

N

L1

L2

L3

N

P1

P2

2"

1.67"

1.67"

Ø.201 thru or

tap for 10-32

Table 1 - Auxiliary Contact Ratings

Device

120VAC 240VAC 480VAC 600VAC

SP

.6A

.3A

–

–

Table 2 - Short Circuit Withstand Ratings

Device

Rating Fuse

Type

1

SP – 600A

30 kA @ 600 VAC

Class L 1400A

2

1 - Short Circuit Rating applies with fusing up to this amperage.

Ratings are based on tests performed with Ferraz Shawmut non-

time Delay Current Limiting fuses.

2 - Tests performed with maximum allowable motor fusing sized per

the 2008 NEC.

Max

Min

SP

777 MCM

2/0

12-14 AWG

Table 3 - Wiring Terminal Capacity

Main Contacts

Aux. Contacts

SP

OPERATING INSTRUCTIONS

A company of MARECHAL ELECTRIC GROUP

MELTRIC Corporation

/ 4765 W. Oakwood Park Drive Franklin, WI 53132

Tel. : 800 433 7642 / Fax : 414 433 2701 / e-mail : mail@meltric.com

INSSP F

A manufacturer of products using

Marechal technology

meltric

.com