Installation Manual: MeMC silvantis 72 cell Pv modules

4 of 13

© Copyright 2012 MEMC Electronic Material

4.0 MeChanICal InsTallaTIon

4.1 PlannIng and desIgn

•

Before installation, check to ensure all sub-structure will accommodate expected system loads. This includes and is not

limited to roof, foundations, mechanical structure, and mechanical connections.

•

For roof installations, utilize a fire-resistant roof covering rated for the application.

•

Mechanical structures should not contact the module backsheet under any expected load conditions

•

Consider the following factors during system design, which will influence performance:

a) MEMC solar modules produce the most power when they are pointed directly at the sun, and should be tilted for

optimum system performance.

b) Proximity to obstructions such as: walls, buildings, trees, groundcover, snow cover, or dust and debris that have the

potential to shade or damage the modules.

c) Elevated temperatures will decrease energy yield, so designs should ensure adequate airflow across the back of the module.

d) Allow a minimum spacing of 10 mm between modules for thermal expansion.

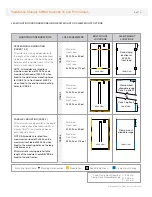

4.2 Module InsTallaTIon oPTIons for MounTIng loCaTIons

For mounting locations for clamps or bolt for specified load, please refer to Table on page 5.

•

Each module should be mounted using four bolts through the mounting holes on the rear side of the module, or with four

clamps over the front side.

•

Depending on the desired load capability of the array, modules may be mounted either perpendicular or parallel to the

structure rails. Clamps can be mounted anywhere inside of the safe mounting range for each case illustrated below (referring

to chart showing clamp and bolt mounting locations).

•

If using bolts, eight mounting holes are provided on the rear side the module frame as shown in Appendix 8.1. Use a stainless

steel bolt stack no smaller than ¼"-20 or M6, with two flat washers and a locking washer as shown in Appendix 8.2.

•

To ensure an adequate clamping area, all clamps used should comply with the following general conditions:

1. Clamp height must correspond to 50 mm frame height

2. Clamp must have a minimum width of 38 mm

3. Clamp depth must be between 6 mm to 10 mm

•

All fasteners used to fix the modules with clamps should be stainless steel, and no smaller than ¼”-20 or M6.

•

To provide adequate fixing or clamping force, torque the minimum recommended fasteners to 6.2 - 8.9 Nm (4.6 - 6.6 ft-lb).

•

All other structural dimensions, such as clamp and rail thickness, should be sized appropriately for the intended site load.