5.0 eleCTrICal InsTallaTIon

5.1 PlannIng and desIgn

•

All modules are manufactured with a sealed junction box and pre-attached cables and locking connectors. These

components should not be modified or tampered with in any way.

noTe: Installers should ensure that the polarized locking connectors are from the same supplier when connected on the

same string. we do not recommend mixing polarized interlocking connectors from different manufacturers—including

connections at the inverter, combiner boxes, and modules.

•

Ensure connectors are clean and dry before establishing connection.

•

Ensure that all wire, fusing and disconnects are appropriately sized for the system design according to national, regional, and

local codes.

•

Electrical characteristics are within plus or minus 5% of rated values for Isc, Voc, Impp and Vmp. Pmax ranges between

-0/+5W at standard test conditions (STC). However, modules will operate under conditions which may be significantly

different than STC. MEMC suggests multiplying specified ratings by a minimum of 1.25* or more when specifying the system

and balance of system components.

1.25* Refer to local codes before planning and design of the system.

•

Determine the maximum number of modules connected in series using the following formula: N

s

= Vmax

s

/ Voc

m

Where:

N

s

equals the maximum modules in series

Vmax

s

equals the maximum system voltage

Please refer to module data sheet for actual Vmax rating, as some models are rated for 600 V UL while others are

1000 V UL.

Voc

m

equals the module open circuit voltage at coldest conditions for the site (refer to local codes)

warnIng: Installers should adhere to all applicable local, regional, and national codes and regulations when designing and

constructing the photovoltaic system.

noTe: In colder climates, it may be necessary to further reduce the maximum number of modules in series by using voc

m

at the minimum expected operating temperature.

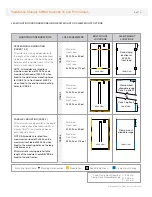

5.2 Module wIrIng

•

The module includes wires and polarized locking connectors from the junction box on the back of the module. The wires

have sufficient length to connect to adjacent modules in either a portrait or landscape configuration. Field replacement of

connectors or cables must be avoided and it will invalidate the product warranty. Polarized locking connectors of the same

type and make are needed for all series string wiring. The maximum operating temperature of wires and connectors should

not exceed 85ºC.

warnIng: It is not recommended to mix connectors from different suppliers within the same string. This includes

connections at the inverter, combiner boxes, and modules.

•

Always wire modules so that proper polarity is maintained. Avoid placing excessive tension on the cables.

•

There is no limit to the maximum number of series strings that can be combined in parallel. However, when doing so, each

string must include overcurrent protection with a maximum rating of 15A. MEMC recommends the use of DC rated fuses or

overcurrent protection devices with the appropriate maximum voltage rating.

•

Do not connect modules directly to a parallel bus.

•

The cross-sectional area of cable and the connector type must be selected to align with the overall system design and should

include the maximum short circuit current of the system, maximum operating temperatures, and cable run lengths.

•

For field connections, use at a minimum #12 AWG/4 mm

2

wires insulated for a minimum of 85°C. Use copper wire only.

Installation Manual: MeMC silvantis 72 cell Pv modules

© Copyright 2012 MEMC Electronic Material

7 of 13