5.3 groundIng

•

The module frame includes several labeled grounding holes. These holes may not be used for any other purpose.

•

MEMC recommends a Burndy BGBL-4 AL lay-in lug for grounding.

•

Only Negative grounding circuits (negative polarity to ground) shall be used within the array design.

•

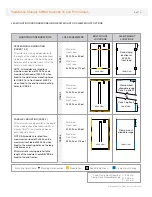

Attach the grounding lug to the frame as follows:

Step 1: Use stainless steel hardware.

Step 2: Place the grounding lug over the grounding hole on the exterior of the module frame.

Step 3: Place a star washer directly between the bottom of the grounding lug and the exterior surface of the frame.

Step 4: Place an M4 or #8-32 bolt through the lug, star washer and frame grounding hole.

Step 5: Secure the lug to the frame using a flat washer, split washer and M4 or #8-32 nut.

Step 6: Torque the bolt stack to approximately 1.5 Newton.meters (or 1.1 foot pounds) to ensure the star washer scratches

the anodized frame.

5.4 eleCTrICal InsTallaTIon warnIngs

•

Installation and maintenance should be performed by qualified personnel only.

•

Use insulated tools during installation, troubleshooting and maintenance of photovoltaic modules.

•

Installers should adhere to all applicable local, regional, and national codes and regulations when designing and constructing

the photovoltaic system.

•

Photovoltaic modules produce DC electrical energy from light. When illuminated, each module can have a DC potential of

greater than 45V and should be handled with care.

•

Disconnecting modules under illumination may cause electrical arcing which may result in burns, fires, or other problems.

Modules connected in series should not be disconnected under illumination.

WARNING: The PV system can generate hazardous voltage even after the system has been disconnected. Follow

standard safety regulations when disconnecting energized modules.

•

Always use a wire management system that keeps wires and cables out of direct contact with edge surfaces which could cut

or damage the insulation. Do not allow wires to rest on the ground or roof surface.

•

The module junction box should not be opened or modified in any way in the field.

•

Additional grounding holes may be added only with the express written consent of MEMC. New grounding holes must be

drilled using an approved drill jig, avoiding damage to the module glass, backsheet, or other module components.

•

Do not use mirrors, lenses, or other techniques to magnify or concentrate additional light on the module.

Installation Manual: MeMC silvantis 72 cell Pv modules

© Copyright 2012 MEMC Electronic Material

8 of 13