85-03-01058-O

FV33i Gen 3

Page

27

3.2.10

Modifying ZC Woodburning Cabinets

This gas fired Insert may be installed in a ZC wood burning cabinet that has been modified by removing the refractory, glass

doors, screen rails, screen mesh, and log grates.

The fireplace flue damper can be fully blocked open or removed for installation of the gas fireplace insert.

Smoke shelves, shields, and baffles may be removed if attached by mechanical fasteners.

Chimney cleanouts must fit properly.

Trim panels or surrounds shall not seal ventilation openings in the fireplace

If the factory-built fireplace has no gas access hole(s) provided, an access hole of 1.5 in (37.5 mm) or less

may be drilled through the lower sides or bottom of the firebox in a proper workmanship-like manner. This

access hole must be plugged with non-combustible insulation after the gas supply line has been installed.”

Cutting any sheet-metal parts of the fireplace, in which the gas fireplace insert is to be installed, is

prohibited by Ansi Z21.88-2017 codes and other fire safety codes.

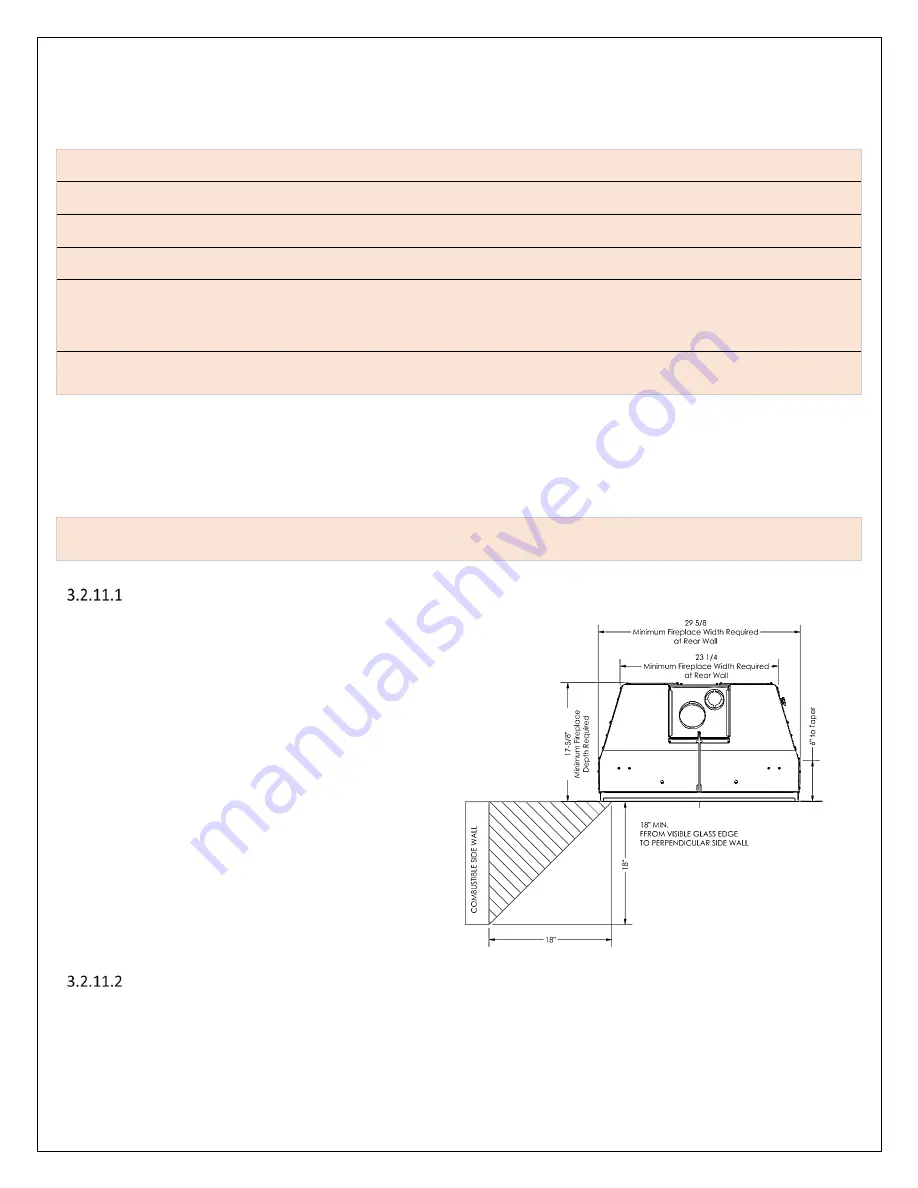

3.2.11

Clearances to Combustible Side Walls

The minimum distance required from the side edge of the visible glass to a combustible side wall is 18”. Combustible side walls,

mantel corbels, mantel legs and other combustible walls and decorative objects must fall behind a 45-degree line extending

outward from the side edges of the visible glass unless such objects are more than 18” away from the visible side edges of the

glass. See

If the required clearance cannot be met to a pre-existing combustible side wall, an NFPA approved clearance

reduction shield, metal or ceramic board, must be added to the side wall.

Horizontal Clearance Reduction by 66%

NPFA 211 Approved

: Install 20-gauge or heavier steel

shield that provides at least a 1” active airspace, on the

combustible wall surface. To provide for active airflow,

install at least 1” metal or ceramic standoffs or spacers

between the metal shield and the combustible surface

being protected. The bottom and top edges of the cavity

between the metal shield and the combustible surface

must be left open. The steel shield must be a minimum

of 12” larger in each direction than the surface area of

the source of heat; or if the surface being protected is

smaller than surface area of the source of heat, this

shield must be larger than the combustible surface in

each direction.

By using this method of protection, if the required

horizontal clearance was 12”, the resulting clearance will

be reduced by 66% to 4” between the heat source and

the metal shield.

Horizontal Clearance Reduction by 50%

NPFA 211 Approved

: Install an R-1 rated ceramic board or R-1 rated mineral board on the wall you are attempting to protect. by

using this method of protection, if the required horizontal clearance was 12”, the resulting clearance will be reduced by 50% to

6” between the heat source and the R-1 Rated wall board.

Side Wall Clearances