85-03-01058-O

FV33i Gen 3

Page

46

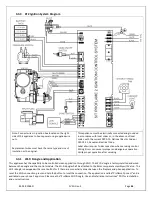

3.4.3

Gas Pressure Requirements and Checking

Two pressure taps for checking input and output gas pressures are located on the main gas valve. A qualified installer should use

this fitting for setting the correct gas pressure during initial installation.

The appliance and its appliance main gas valve

must be disconnected from the gas supply

piping system during any pressure testing of

that system at test pressures in excess of 1/2

psi (3.5 kPa).

The appliance must be isolated from the gas

supply piping system by closing its equipment

shut-off valve during any pressure testing of

the gas supply piping system at test pressures

equal to or less than 1/2 psi (3.5 kPa).

If the factory-built fireplace has no gas access hole(s)

provided, an access hole 1.5” or less may be drilled

through the lower sides or bottom of the firebox in a

proper workmanship like manner. This access hole

must be plugged with non- combustible insulation after

the gas supply line has been installed.

3.4.4

Drip Leg Recommended

It is recommended that a drip leg/sediment trap is installed

within the main gas supply line serving this appliance.

3.4.5

Manual Gas Shutoff Valve Requirement

If local building codes require one, obtain an external keyed wall-mounted or

floor-mounted manual gas shutoff valve approved per local gas plumbing codes

and install per local gas plumbing codes in the specified location. Local

requirements supersede all other codes.

Main Gas Valve

Drip Leg/ Sediment Trap

Keyed Manual Gas Shutoff Valve