GAS PRESSURE REQUIREMENTS

A MAJOR CAUSE OF OPERATING PROBLEMS WITH GAS APPLIANCES CAN BE IMPROPER GAS PRESSURE!

Such problems as changes in flame color or configuration, gas pilot or burner outages, intermittent operation,

changes in heat output, excessive burner noise, etc. are nearly always the result of changes in gas pressure or

improper gas pressure at the time of the installation. The most important item to check during the installation and the

first thing to check when problems occur is gas pressure!

Gas supplies normally enter a residence at 1/2 PSI (13" - 15" W.C.) (3. KPA). A regulator is then placed inside the

residence, which drops this pressure to 7" W.C. (1.8 KPA) (Nat. Gas). This "inches to inches" regulator is of

adequate capacity to service the gas appliances (such as dryer, furnace, etc.). If this regulator's capacity is not

sufficient to add the Gas Stove, an additional "inches to inches" regulator must be installed for the Stove.

EXCEPTION: Some codes allow 2 PSI (1.4KPA) supplies to enter the residence, in which case "pounds to inches"

regulators are used.

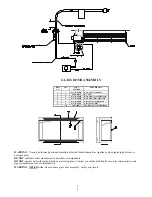

The following table provides information on correct gas pressure requirements. Be sure your gas supplier or

plumber carefully follows this table.

INLET GAS SUPPLY PRESSURE

DESIRED

PRESSURE

MINIMUM

PRESSURE

MAXIMUM

PRESSURE

MANIFOLD

PRESSURE *

AIR SHUTTER

POSITION

NATURAL GAS

7.0" W.C.

5" W.C.

11" W.C.

3.5" W.C.

1/8

" OPEN

L.P. GAS

11.0" W.C.

11" W.C.

13.0" W.C.

10.0" W.C.

1/2

" OPEN

* TURN GAS VALVE KNOB TO "HIGH" POSITION. GAS PRESSURES MAY VARY PLUS OR MINUS 5%

* Manifold pressure must be taken at the outlet "manifold" tap and inlet pressure at "inlet" tap with the burner

operating by a qualified installer (see Figure 7: Pressure Test Port).

NOTE: for high altitude (above 5,000 feet) some variations in air shutter settings may be required. (See Pg. 24)

Figure 7: Pressure Test Ports

1

7

Summary of Contents for MEDALLION

Page 21: ...Log Fire View Figure 9 Log Module 2 0...

Page 33: ...NOTES NOTES 3 2...