Operating Instructions - CPC6050

121

Modular Pressure Controller

CPC6050

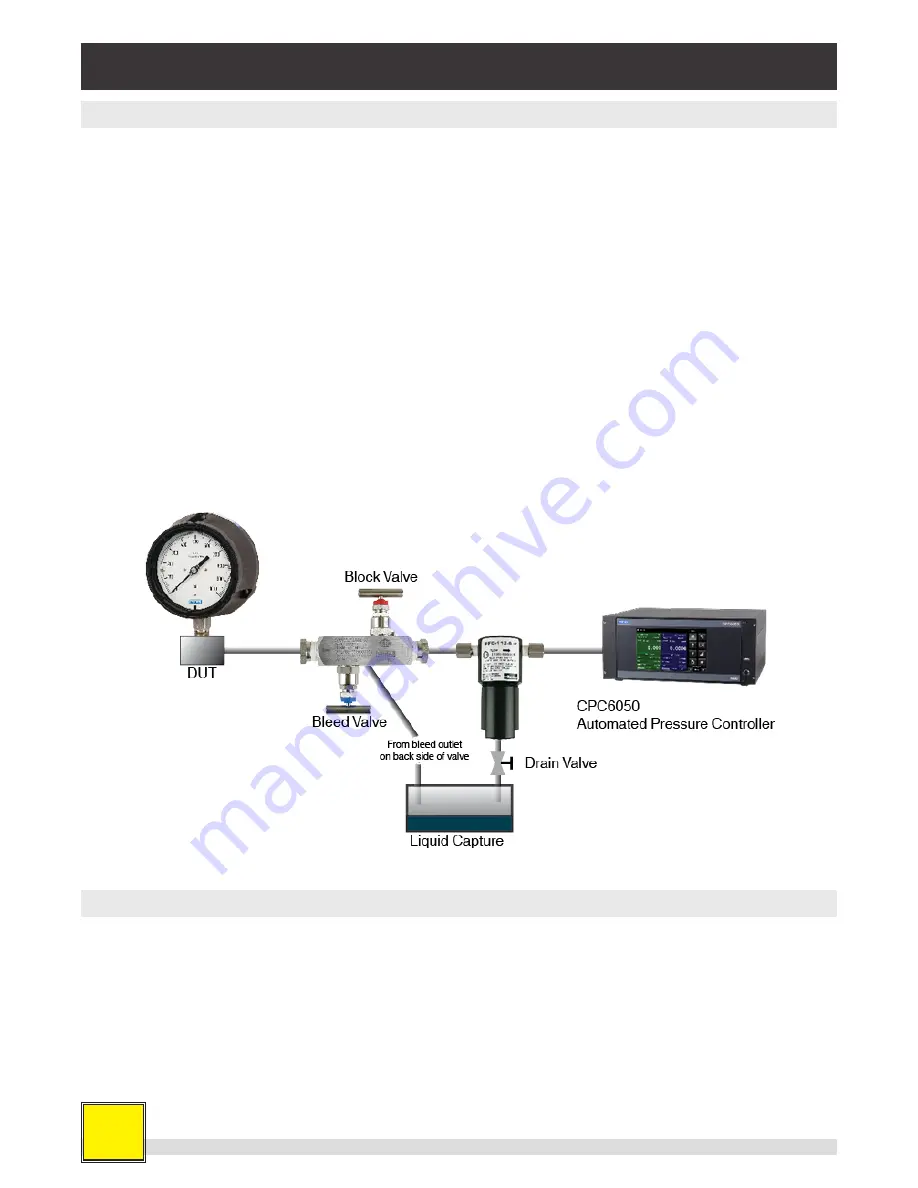

8.10.2 Block and Bleed Valve (CPX-A-C5-8)

The block and bleed valve is used to purge the liquid from the device under test. It is a three-way valve

which blocks the instrument from being contaminated while bleeding the liquid out of the device under

test. An initial bleeding of the contaminants in the system can be done by the following procedure

• Before connecting the DUT to the system, remove as much liquid as possible from the DUT.

• With the controller power off and both the block and bleed valve closed, connect the system as shown

below.

• Use the controller to apply a pressure close to the full scale pressure of the DUT.

• Open the block valve slowly to pressurize the DUT. (note: the gas will flow in the direction of the con-

troller to the DUT: high pressure to low pressure).

• After the system is pressurized close the block valve.

• Open the bleed valve and purge the system to atmospheric pressure. Observe the sump to see if any

liquid is purged.

• Close the bleed valve.

• Repeat steps 3 to 7 until no more liquid is observed coming out of the system.

• With the block and the bleed valves securely closed, vent the controller.

Figure 8.10.2 – Contamination prevention accessories

8.11 Vacuum Regulator

Vacuum Regulator accessory reduces the vacuum pressure flowing through the exhaust port. The reduc-

tion in vacuum prevents the pressure swings caused when switching modes. These pressure swings

occur on bidirectional pressures lower than 10 psig full span. The vacuum regulator accessory is recom-

mended to have a smooth transition between Measure and Control modes in this pressure range.

The Vacuum regulator is installed at the Exhaust port of a pressure channel on the CPC6050 (Figure

8.11-A). The installation should only allow the direction of pressure flow away from the controller. This

is indicated on the vacuum regulator (Figure 8.11-B). The pressure connection to an external vacuum

pump is 1/8" NPT connection.

i

Notice