20

Operating Instructions - CPC6050

Modular Pressure Controller

CPC6050

4.3 Approvals and Certificates

EC declaration of conformity

EMC directive

11)

EN 61326-1 emission (group 1, class A) and interference immunity (industrial application)

Low voltage directive

EN 61010-1

RoHS directive

2011/65/EU, article 4

Certificate

Calibration

12)

Standard: A2LA calibration certificate (standard on factory)

Option: DKD/DAkkS calibration certificate

11) Warning! This is class A equipment for emissions and is intended for use in industrial environments. In other environments, e.g. residential or commercial installations, it can intefere with

other equipment under certain conditions. In such circumstances the operator is expected to take the appropriate measures.

12) Calibration in a horizontal position/operating position.

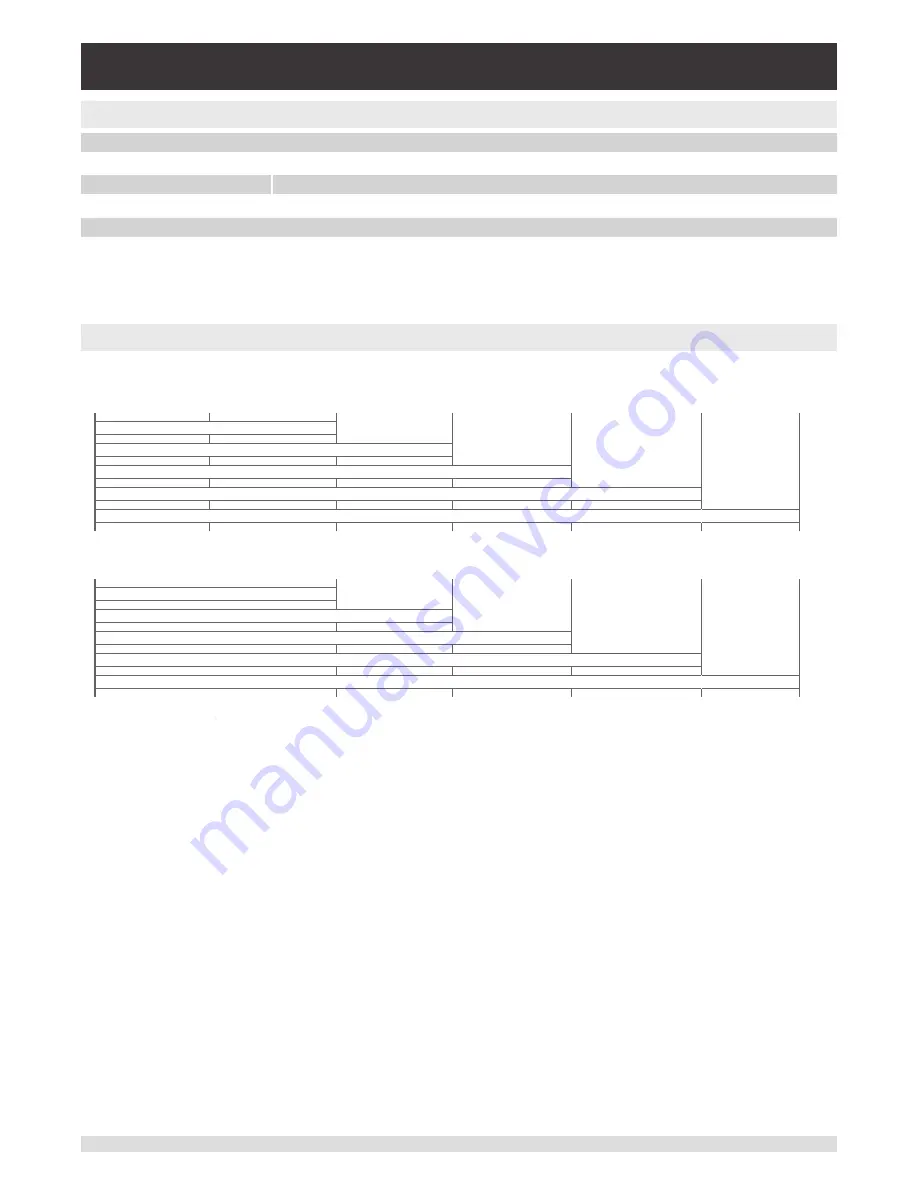

4.4 Working Ranges of the Controller Modules

Bi-directional or gauge pressure [bar (psi)]

1)

-1 (-15)

0

1 (15)

3.4 (50)

10 (150)

100 (1,500)

210 (3,045)

LPPump MODULE ±12.5 mbar (±0.18 psi)

2)

LPSVR MODULE ±12.5 mbar (±0.18 psi)

2)

MPSVR MODULE ±0.35 bar (±5 psi)

2)

HPSVR MODULE -1 ... 5 bar (-15 ... +75 psi)

2)

EPSVR MODULE -1 ... 10 bar (-15 ... +150 psi)

2)

Absolute pressure [bar (psi)]

1)

0

2 (30)

4.4 (65)

11 (165)

101 (1,515)

211 (3,060)

LPPump MODULE 0 ... 0.5 bar (0 ... 7.5 psi)

2)

LPSVR MODULE 0 ... 0.5 bar (0 ... 7.5 psi)

2)

MPSVR MODULE 0 ... 1 bar (0 ... 15 psi)

2)

HPSVR MODULE 0 ... 6 bar (0 ... 90 psi)

2)

EPSVR MODULE 0 ... 11 bar (0 ... 165 psi)

2)

1) Mixing of absolute pressure and gauge pressure transducers in a module is not possible.

2)

Smallest acceptable transducer range including turndown ranges.

For controlling absolute pressure a vacuum pump connected at the Exhaust port is required.