24

Operating Instructions - CPC6050

Modular Pressure Controller

CPC6050

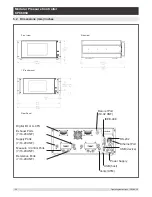

5.4.2 Supply Port

The pressure supplied to the pressure connection labeled “Supply” should be approximately 10% higher

than the full scale of the highest pressure transducer installed in the controller channel or 10 psi, which-

ever is greater. With a Pump Module, supply pressure is turned off for primary transducers with pressure

ranges less than 3 psi. Supply pressure to a Pump Module is only necessary if it is called for to increase

the control speed. In this mode, a Pump Module will use the supply pressure to quickly control close to

the set point before the internal pump takes over and ramps into the set point with precision.

5.4.3 Exhaust Port

The pressure connection labeled “Exhaust” is for the vacuum supply. In a gauge pressure version it can

be left open to atmospheric pressure.

5.4.4 Vent Port

The pressure connection labeled “Vent” is the port where the system pressure is vented to the atmo-

sphere under certain conditions. Leave this port as is.

5.4.5 Measure / Control Port

The Measure / Control port (when in the Control mode) supplies pressure that is precisely controlled by

the controller. In the Measure mode, a pressure applied to the Measure / Control port is measured by the

internal transducers.

5.4.6 Reference Port

The reference port is available on gauge units that have transducers that are not sealed gauge units. For

these units this port is available to connect to the reference side of the transducer. This port is normally

left open to atmosphere but may be connected to a stable reference pressure. In an absolute pressure

transducer this port is not used.

5.4.7 Barometric Reference Port

The Barometric Reference port is connected to the optional internal barometer and should be left open to

atmospheric pressure.

5.5 Remote Communication Connections

See Section 7, Remote Operation, for connections and commands for operation over IEEE-488, Ether-

net, USB or RS-232 ports.

5.6 Power Up

Apply power to the power connector on the rear of the instrument using the power adaptor included, and

switch the power switch on the front of the unit ON. The instrument will go through an initialization pro-

cess and system check. As soon as the system check is completed the system will default to a screen

similar to the one shown in Section 6.1.2 - Display Screen Features. The main measurement screen may

be configured in many different ways but initially it will be in a default configuration. Subsequently, the unit

will power up in the configuration that it was in when last powered off. Allow at least 15 minutes of warm

up before performing critical pressure measurements.

Do not position the equipment so that it is difficult to remove the power cord. The instrument

is not intended for connection of long-distance lines, i.e. lines within a building that are longer

than 30 m, or that leave the building (including lines of outdoor installations).