High-End Pressure Controller

CPC8000

76

Operating Instructions - CPC8000

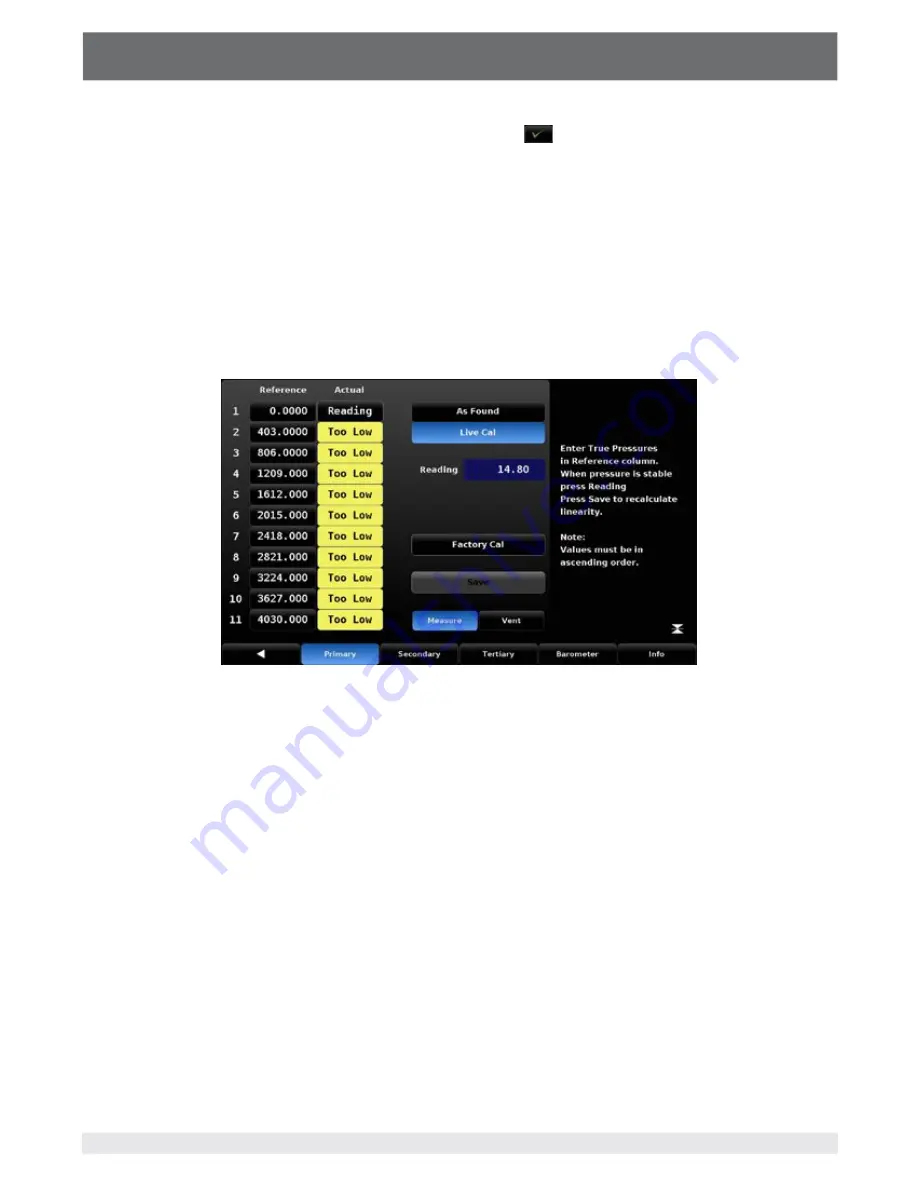

sponding point in the “Reference” or “Actual” columns and a data entry keypad will appear on the side

bar. Enter and accept the point using the key pad and check [

]. Pressing the [Save] button linearizes

the internal sensor based on the “As Found” data entered.

Linearization can also be accomplished for each transducer in a “live Calibration” by pressing the

[Linearize] / [Live Cal] button. The Live Cal allows the calibration technician to perform the calibration and

linearization for each sensor in a more direct way. In the Live Cal, the reference standard is connected

to the Measure/Control port and the CPC8000 is placed in Measure mode. Choose the transducer

to be tested by pressing the [Primary], [Secondary], [Tertiary], or [Barometer] button. The reference

pressure generated by the standard is recorded in the “Reference” column for each point. The reading

of the internal transducer for each pressure point can be seen directly in the “Reading” window. Pressing

the corresponding point under the “Actual” column will accept that reading into that point. Subsequent

pressure points generated by the pressure standard are accepted and recorded in the same way. After all

points are entered, press the [Save] button to linearize the internal sensor based on the “Live Cal” data.

Figure 7.5.2.5.3b - Live Cal

At any time the [Factory Cal] button can be pressed to revert back to the factory calibration.

The Reference points and Actual points can also be sent over the remote bus for automated sensor

linearizations. First ensure the instrument is not in Autorange by sending “Sensor <n>” where <n> is the

sensor you wish to linearize, or by bringing up the Linearization screen from the Applications menu (this

automatically takes the CPC8000 out of autorange). Set each reference pressure with the command

“Desiredpress <n>,<pressure>” where <n> is the 0th based index. “Desiredpress 0,0” will set the 1st

Reference point’s value to 0. “Desiredpress 1,1.5” will set the 2nd reference point to 1.5, etc. Each subse-

quent reference point must be greater in value than the previous point. It is advised to send all of your

Reference points frst before proceeding. Use your reference (e.g. CPB6000) to control the pressure on

the measure port to the Reference/desired pressure. Then send the pressure reading over the bus with

the command “Actualpress <n>,<reading>” where <n> is the 0th based index. This reading should be

/- 1%FS of the Reference point. Using Figure 7.5.2.5.3a for example, if you have sent “Desired-

press 3,1209.0”, you would send “Actualpress 3,<reading>” where <reading> must be between 1168.70

and 1249.30. Send each of the 11 readings with the “Actualpress” command and then send “Calculate_

as_found_linearity” and then “Save_linearity”. Your active sensor linearization is now complete.

Summary of Contents for CPC8000

Page 6: ...High End Pressure Controller CPC8000 6 Operating Instructions CPC8000 NOTES ...

Page 10: ...High End Pressure Controller CPC8000 10 Operating Instructions CPC8000 NOTES ...

Page 24: ...High End Pressure Controller CPC8000 24 Operating Instructions CPC8000 NOTES ...

Page 84: ...High End Pressure Controller CPC8000 84 Operating Instructions CPC8000 Notes ...

Page 112: ...High End Pressure Controller CPC8000 Operating Instructions CPC8000 113 NOTES ...