High-End Pressure Controller

CPC8000

100

Operating Instructions - CPC8000

9.4 Model 75 Pressure Booster System

To control pressure, the CPC8000 requires a pressure supply of 10% above the full scale of the instru-

ment. For ranges of 3000 psi or greater, this is above the typical gas bottle/cylinder. The Model 75

Pressure Booster System provides the ability to boost bottle pressure up to the supply pressure require-

ments of all possible CPC8000 range confgurations while maximizing gas bottle/cylinder usage.

The Model 75 is a single piston air driven gas booster mounted in a heavy duty roll bar frame. The unit

includes an operator control panel with gauges for supply pressure, output reference pressure and an

output vent valve. The system requires shop air to drive the booster and a minimum of 300 psi to 3000

maximum inlet pressure (clean dry air or Nitrogen).

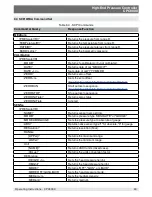

Table 9.4 - Specifcations for Input Supply Pressure and Output Pressure

Input Supply

Pressure

Minimum: 300 psi

Maximum: 3000 psi

Media: Clean Dry Inert Gas (Nitrogen preferred)

Output

Pressure

6500 psi typical

7000 psi relief valve setting

Please refer to the Model 75 data sheet (CDS075) for additional information and specifcations, available

on our web site at www.mensor.com.

Figure 9.4 - Model 75 Pressure Booster System

Summary of Contents for CPC8000

Page 6: ...High End Pressure Controller CPC8000 6 Operating Instructions CPC8000 NOTES ...

Page 10: ...High End Pressure Controller CPC8000 10 Operating Instructions CPC8000 NOTES ...

Page 24: ...High End Pressure Controller CPC8000 24 Operating Instructions CPC8000 NOTES ...

Page 84: ...High End Pressure Controller CPC8000 84 Operating Instructions CPC8000 Notes ...

Page 112: ...High End Pressure Controller CPC8000 Operating Instructions CPC8000 113 NOTES ...