High-End Pressure Controller

CPC8000

Operating Instructions - CPC8000

81

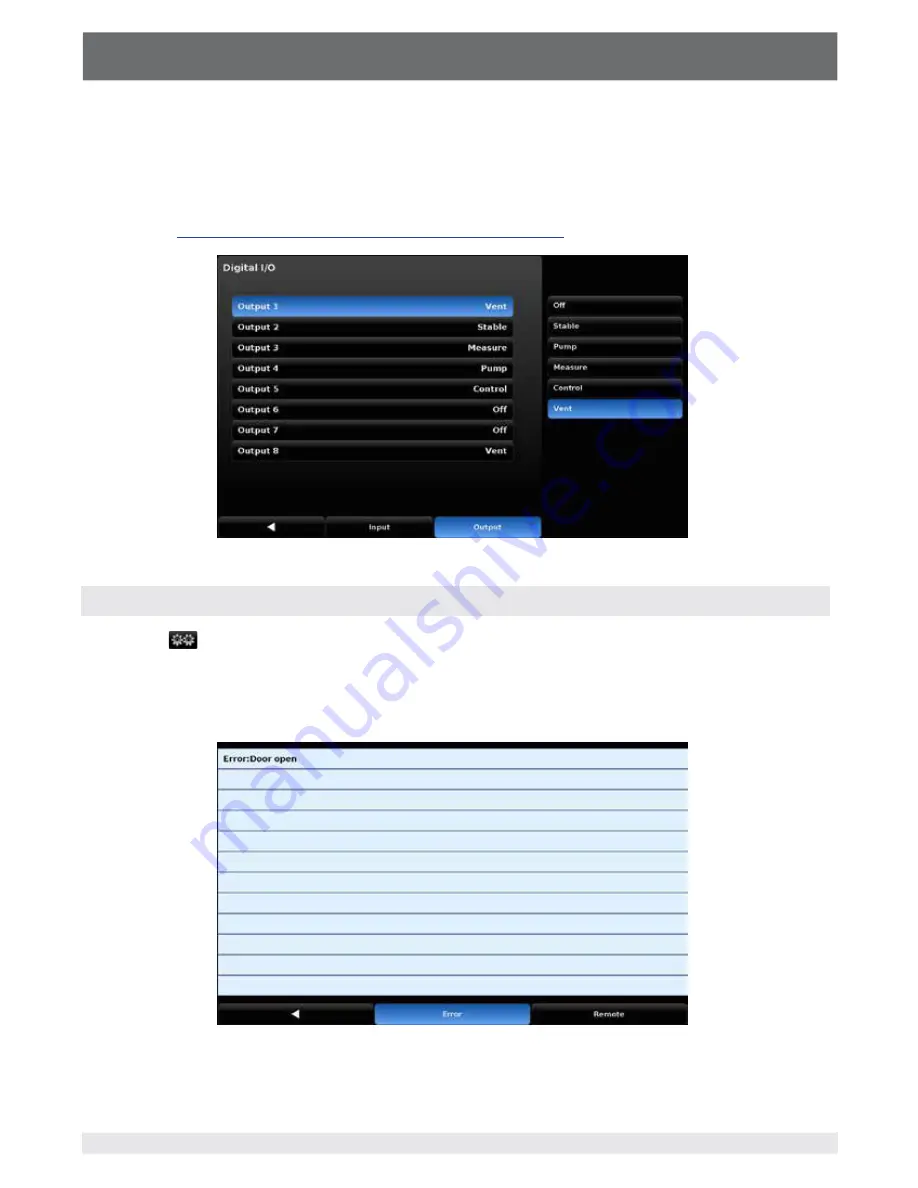

In fgure 7.5.2.5.8b Output 1 (one) is assigned to the [Vent] mode of the instrument. Output 1 will be

energized when the CPC8000 is in Vent mode. Each output can be assigned to one of the choices listed

on the right by pressing the output and then the choice. Each output switch will be energized when

the assigned instrument mode is active. When the mode is inactive the assigned output switch will be

de-energized. The “Pump” choice indicates that the regulator requires a vacuum pump to be on in order

to control to a sub-atmospheric pressure. The pump output is used to turn on or of a vacuum pump as

Section 5.7, Electrical & Communication Connections

Figure 7.5.2.5.8b - Digital Output

7.5.2.5.9 Troubleshoot

The Setup [

] / {Applications] / [Troubleshoot] screen provides a list of internal or remote errors that

may have occurred. Figure 7.5.2.5.9 below gives an indication that the CPC8000 access door has been

opened. Once the errors have been viewed in this screen, they are cleared. The [Remote

tab shows communication send/receive messages that have been made through one of the remote

communication ports and is helpful in de-bugging remote control software programs.

Figure 7.5.2.5.9 - Troubleshoot

Summary of Contents for CPC8000

Page 6: ...High End Pressure Controller CPC8000 6 Operating Instructions CPC8000 NOTES ...

Page 10: ...High End Pressure Controller CPC8000 10 Operating Instructions CPC8000 NOTES ...

Page 24: ...High End Pressure Controller CPC8000 24 Operating Instructions CPC8000 NOTES ...

Page 84: ...High End Pressure Controller CPC8000 84 Operating Instructions CPC8000 Notes ...

Page 112: ...High End Pressure Controller CPC8000 Operating Instructions CPC8000 113 NOTES ...