67

WIKA operating instructions hydraulic high pressure controller model CPC8000-H

PN 0018708001B 11/2020 EN

EN

8.2.1 Beyond the Warranty

Take advantage of Mensor’s expert product care. Mensor provides complete maintenance and calibration services, available for

a nominal fee. Our service staff is knowledgeable in the innermost details of all of our instruments. We maintain units that are in

operation in many different industries and in a variety of applications, and by users with a wide range of requirements. Many of

these instruments have been in service for years, and continue to produce excellent results. Returning your instrument to Mensor

for service benefits you in several ways:

• Our extensive knowledge of the instrument assures you that it will receive expert care.

• In many cases we can economically upgrade an older instrument to the latest improvements.

• Servicing our own instruments which are used in “real world” applications keeps us informed as to the most frequent services

required. We use this knowledge in our continuing effort to design better and more robust instruments.

• Repair or replacement of the CPC8000-H chassis, hydraulic module and measurement transducers will be available up to 7

years after the production life cycle of the product, pending external vendor parts or equivalent parts availability. The production

life cycle is defined as the time from the product series launch to the announcement of discontinuation (typically 8 to 10 years).

• All repairs associated with the chassis or internal modules should be performed by Mensor due to the complexity of performing

these repairs. Replacement of measurement transducers and media refill can be done at the customer’s site.

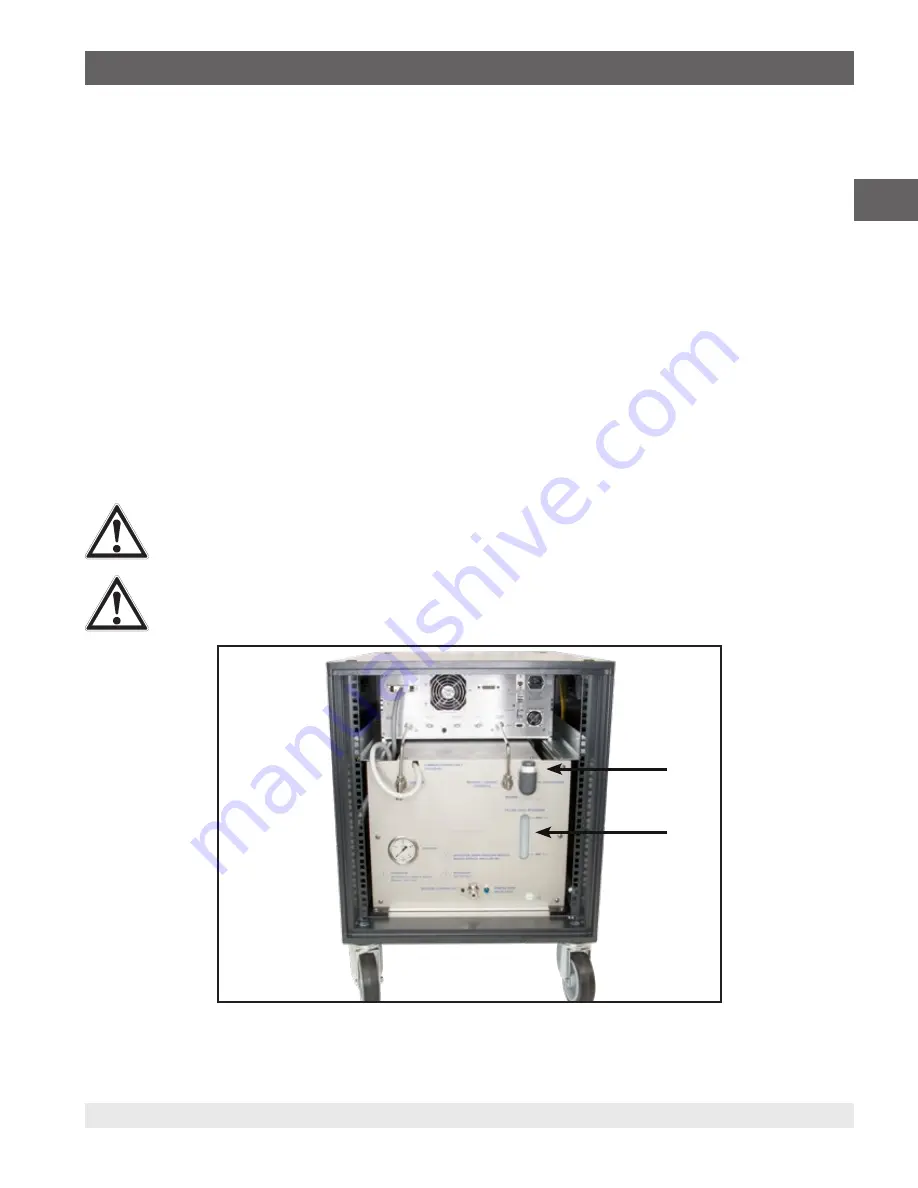

8.2.2 Hydraulic Media Filling

The rear panel of the CPC8000-HM provides a filling nozzle for the hydraulic media in the upper right corner of the hydraulic

module. The fill requirements can be seen on the rear panel through a media level window that shows the minimum and maximum

levels of fluid. If the reservoir is empty, the instrument needs ~2 liters of fluid to prefill itself. Any external connections should be

prefilled with fluid before connecting to the CPC8000-H.

WARNING!

Air contaminated media will affect functionality. During the filling process, it is recommended that the external

connections be free of any air molecules to prevent longer pump times and compressibility.

WARNING!

Do not overfill the media reservoir!

Filling nozzle is connected to the media reservoir. This tank can leak if the reservoir is overfilled or tilted. If an

external reservoir is used, stabilize the reservoir on a flat surface.

Figure 8.2.2 Rear Panel

8. Maintenance and Recalibration

Filling Nozzle

Media Level Window