Summary of Contents for SHARK 282

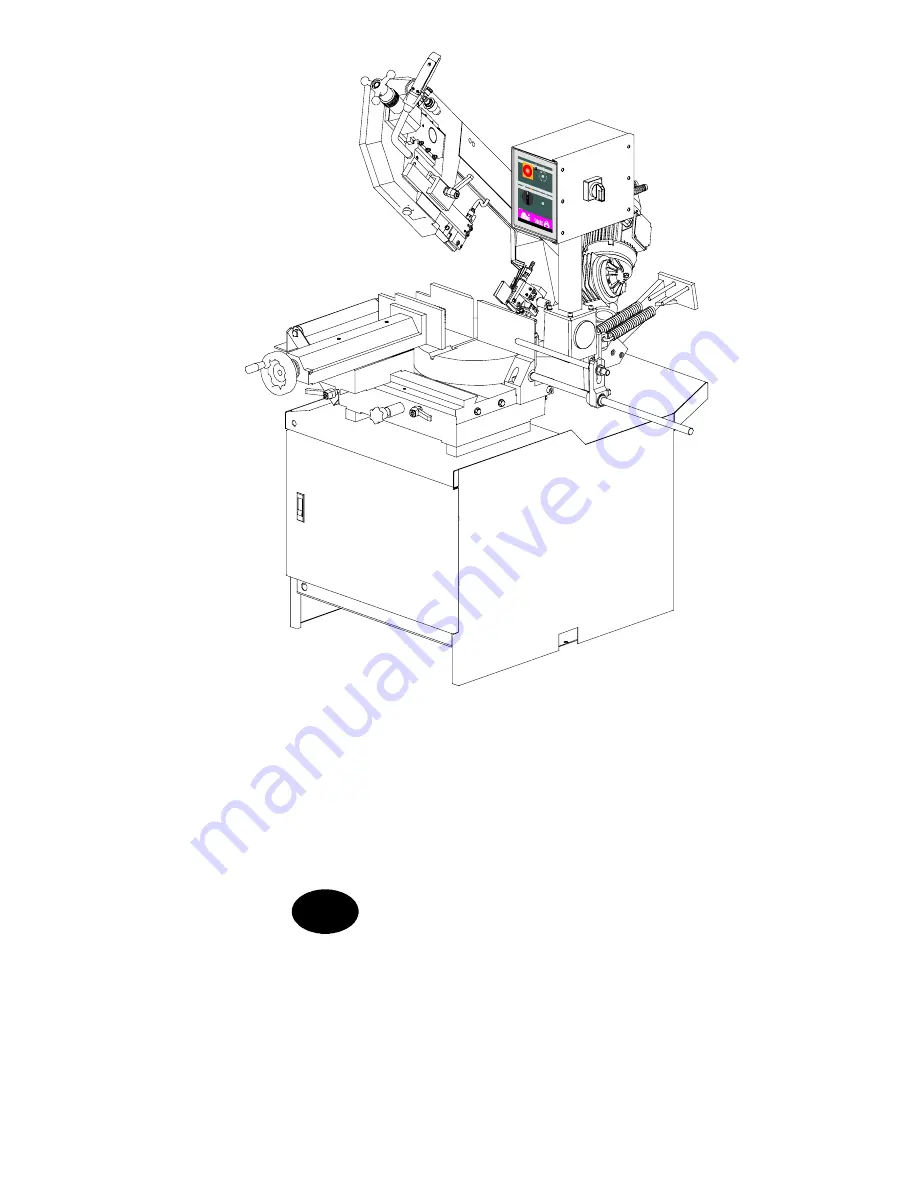

Page 1: ...USE AND MAINTENANCE MANUAL YEAR OF MANUFACTURE ______________ SHARK 282 EN...

Page 2: ......

Page 4: ......

Page 8: ......

Page 59: ...6 7 51 Diagrams exploded views and replace Standardised Wiring Diagrams CENELEC Standard...

Page 60: ...MEP S p A 6 8 52 Use and maintenance manual SHARK 282...

Page 61: ...6 9 53 Diagrams exploded views and replace...

Page 62: ...MEP S p A 6 10 54 Use and maintenance manual SHARK 282...

Page 63: ...6 11 55 Diagrams exploded views and replace...

Page 64: ...MEP S p A 6 12 56 Use and maintenance manual SHARK 282...

Page 65: ...6 13 57 Diagrams exploded views and replace...

Page 66: ...MEP S p A 6 14 58 Use and maintenance manual SHARK 282...

Page 67: ...6 15 59 Diagrams exploded views and replace...

Page 68: ...MEP S p A 6 16 60 Use and maintenance manual SHARK 282...

Page 69: ...6 17 61 Diagrams exploded views and replace...

Page 70: ...MEP S p A 6 18 62 Use and maintenance manual SHARK 282...

Page 71: ...6 19 63 Diagrams exploded views and replace...

Page 72: ...MEP S p A 6 20 64 Use and maintenance manual SHARK 282...

Page 73: ......

Page 76: ...MEP S p A 6 24 67 Use and maintenance manual SHARK 282 Front flywheel assembly 282...

Page 78: ...MEP S p A 6 26 69 Use and maintenance manual SHARK 282 Motor flywheel assembly 282...

Page 80: ...MEP S p A 6 28 71 Use and maintenance manual SHARK 282 Cutting head cover 282...

Page 82: ...MEP S p A 6 30 73 Use and maintenance manual SHARK 282 Vice assembly 282...

Page 84: ...MEP S p A 6 32 75 Use and maintenance manual SHARK 282 Base assembly 282...

Page 86: ...MEP S p A 6 34 77 Use and maintenance manual SHARK 282 Control panel...

Page 88: ...MEP S p A 6 36 79 Use and maintenance manual SHARK 282 Handgrip 3OUT3 SHARK 282...

Page 90: ...MEP S p A 6 38 81 Use and maintenance manual SHARK 282 Fixed work table and turntable 282...

Page 92: ...MEP S p A 6 40 83 Use and maintenance manual SHARK 282 Optional Cut Control System...

Page 94: ...MEP S p A 6 42 85 Use and maintenance manual SHARK 282 Supplementary pneumatic vice 282...

Page 96: ......

Page 151: ......

Page 152: ......