MEP S.p.A.

9--6

116

Use and maintenance manual

SHARK 282

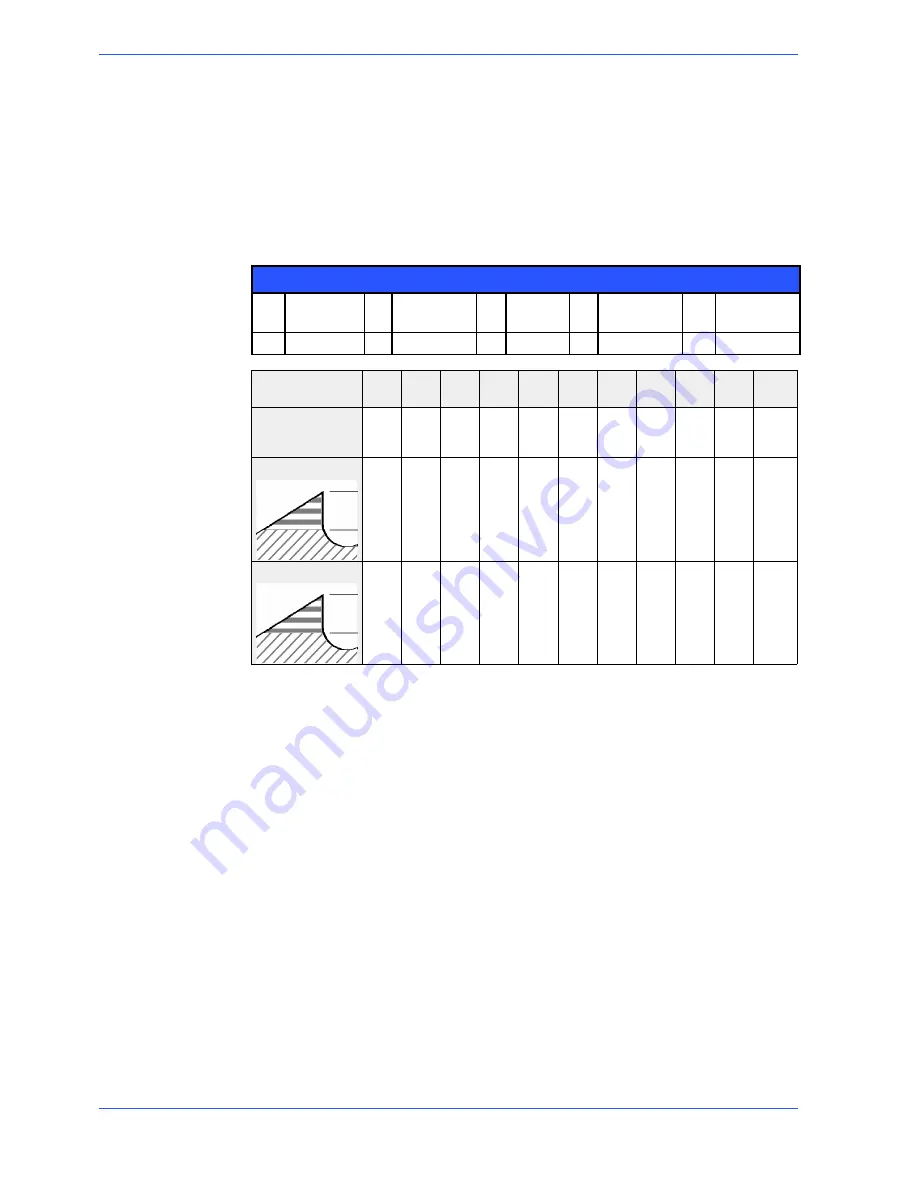

Blade structure

The most commonly used blades are the bimetal types, i.e. manufactured with a

silicon steel body and having a high fatigue strength, and super high---speed steel

teeth; the two parts are welded by electronic or laser---welding.

Standardised teeth types are termed M2 and M42; the difference being that M42

teeth are harder due to the addition of cobalt to the steel used to make the teeth.

Key

Mo Molybden

um

Ni Nickel

Si Silicon

V Vanadium

W Tungsten

Al Aluminium C Carbon

Co Cobalt

Cr Chromium

Mn Manganese

HSS M2

HSS M42

C

Mn

Si

W

Mo

V

Ni

Co

Al HRC

Cr

0,47 0,75 0,22 1,00

1,00 0,12 0,52

0,08 45--50

0,85 0,25 0,30 4,15

6,37 5,00 1,92

64--66

1,07 0,25 0,20 3,75 1,50 9,50 1,15

8,00

67--69

HRC 67--68

HRC 45--50

HRC 65--66

HRC 45--50

TYPE OF

BLADE

The numbers in the columns indicate the % content of the element in the steel.

Blade types

The blades mounted on the

SHARK 282

are 2.950 x 27 x 0.9 mm.; the length can

vary between 2.960 mm. and 2.940 mm., thanks to the blade tensioner device. The

blades, however, apart from size and tooth pitch, are differentiated by other

geometrical characteristics which determine their specialised uses:

H

tooth cutting angle (rake), can be

ٛ

0 or positive;

H

the tooth pitch can be constant or variable;

H

the set, i.e. the various teeth alignments, have many possible configurations.

N.B.

Summary of Contents for SHARK 282

Page 1: ...USE AND MAINTENANCE MANUAL YEAR OF MANUFACTURE ______________ SHARK 282 EN...

Page 2: ......

Page 4: ......

Page 8: ......

Page 59: ...6 7 51 Diagrams exploded views and replace Standardised Wiring Diagrams CENELEC Standard...

Page 60: ...MEP S p A 6 8 52 Use and maintenance manual SHARK 282...

Page 61: ...6 9 53 Diagrams exploded views and replace...

Page 62: ...MEP S p A 6 10 54 Use and maintenance manual SHARK 282...

Page 63: ...6 11 55 Diagrams exploded views and replace...

Page 64: ...MEP S p A 6 12 56 Use and maintenance manual SHARK 282...

Page 65: ...6 13 57 Diagrams exploded views and replace...

Page 66: ...MEP S p A 6 14 58 Use and maintenance manual SHARK 282...

Page 67: ...6 15 59 Diagrams exploded views and replace...

Page 68: ...MEP S p A 6 16 60 Use and maintenance manual SHARK 282...

Page 69: ...6 17 61 Diagrams exploded views and replace...

Page 70: ...MEP S p A 6 18 62 Use and maintenance manual SHARK 282...

Page 71: ...6 19 63 Diagrams exploded views and replace...

Page 72: ...MEP S p A 6 20 64 Use and maintenance manual SHARK 282...

Page 73: ......

Page 76: ...MEP S p A 6 24 67 Use and maintenance manual SHARK 282 Front flywheel assembly 282...

Page 78: ...MEP S p A 6 26 69 Use and maintenance manual SHARK 282 Motor flywheel assembly 282...

Page 80: ...MEP S p A 6 28 71 Use and maintenance manual SHARK 282 Cutting head cover 282...

Page 82: ...MEP S p A 6 30 73 Use and maintenance manual SHARK 282 Vice assembly 282...

Page 84: ...MEP S p A 6 32 75 Use and maintenance manual SHARK 282 Base assembly 282...

Page 86: ...MEP S p A 6 34 77 Use and maintenance manual SHARK 282 Control panel...

Page 88: ...MEP S p A 6 36 79 Use and maintenance manual SHARK 282 Handgrip 3OUT3 SHARK 282...

Page 90: ...MEP S p A 6 38 81 Use and maintenance manual SHARK 282 Fixed work table and turntable 282...

Page 92: ...MEP S p A 6 40 83 Use and maintenance manual SHARK 282 Optional Cut Control System...

Page 94: ...MEP S p A 6 42 85 Use and maintenance manual SHARK 282 Supplementary pneumatic vice 282...

Page 96: ......

Page 151: ......

Page 152: ......