10--9

131

Troubleshooting

SOLUTION

PROBABLE CAUSE

PROBLEM

BMT not energised (Minimum

Tension Coil)

'

Electrical power supply

.

Check: the phases; the

cables; the plug; the socket.

'

BMT Reset switch

.

Make sure that the minimum

tension coil is energised

when switch is turned from 0

to 1. If it is not, replace the

switch.

'

Emergency stop pushbutton

in

.

Make sure the emergency

stop button is released: turn

it clockwise through 1/4 of a

turn to release it.

Electropump is not working

'

Electrical supply

.

Check: phases, cables, plug,

socket and fuse no. 5 in the

electrical plant

'

No--return valve

.

Clean, if blocked replace

'

Filter

.

Clean

The pressure gauge does not

give blade tension pressure

'

Oil level

.

Top up oil level in blade

tensioner cylinder

'

Blocked connection

.

Check for blockages

'

Broken

.

If damaged, replace

Cutting vice will not close or will

not open (MA version)

'

VM: Cutting Vice Valve

.

Make sure the valve is

operating correctly, replace if

necessary.

'

Vice cylinder

.

Check that air is not leaking

through the cylinder seals, by

removing the hose (from the

quick connector), where

there is no pressurized air,

and checking whether air

escapes from the joint. If air

is escaping, replace the

seals or the entire cylinder.

'

Compressed air supply hose

.

Check the hose is not kinked

or blocked. Remove the

obstruction.

'

Air treatment unit

.

Check that the air treatment

group is supplying the

pressure shown on the

gauge.

Summary of Contents for SHARK 282

Page 1: ...USE AND MAINTENANCE MANUAL YEAR OF MANUFACTURE ______________ SHARK 282 EN...

Page 2: ......

Page 4: ......

Page 8: ......

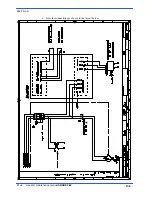

Page 59: ...6 7 51 Diagrams exploded views and replace Standardised Wiring Diagrams CENELEC Standard...

Page 60: ...MEP S p A 6 8 52 Use and maintenance manual SHARK 282...

Page 61: ...6 9 53 Diagrams exploded views and replace...

Page 62: ...MEP S p A 6 10 54 Use and maintenance manual SHARK 282...

Page 63: ...6 11 55 Diagrams exploded views and replace...

Page 64: ...MEP S p A 6 12 56 Use and maintenance manual SHARK 282...

Page 65: ...6 13 57 Diagrams exploded views and replace...

Page 66: ...MEP S p A 6 14 58 Use and maintenance manual SHARK 282...

Page 67: ...6 15 59 Diagrams exploded views and replace...

Page 68: ...MEP S p A 6 16 60 Use and maintenance manual SHARK 282...

Page 69: ...6 17 61 Diagrams exploded views and replace...

Page 70: ...MEP S p A 6 18 62 Use and maintenance manual SHARK 282...

Page 71: ...6 19 63 Diagrams exploded views and replace...

Page 72: ...MEP S p A 6 20 64 Use and maintenance manual SHARK 282...

Page 73: ......

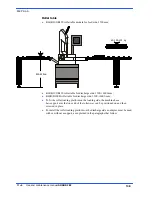

Page 76: ...MEP S p A 6 24 67 Use and maintenance manual SHARK 282 Front flywheel assembly 282...

Page 78: ...MEP S p A 6 26 69 Use and maintenance manual SHARK 282 Motor flywheel assembly 282...

Page 80: ...MEP S p A 6 28 71 Use and maintenance manual SHARK 282 Cutting head cover 282...

Page 82: ...MEP S p A 6 30 73 Use and maintenance manual SHARK 282 Vice assembly 282...

Page 84: ...MEP S p A 6 32 75 Use and maintenance manual SHARK 282 Base assembly 282...

Page 86: ...MEP S p A 6 34 77 Use and maintenance manual SHARK 282 Control panel...

Page 88: ...MEP S p A 6 36 79 Use and maintenance manual SHARK 282 Handgrip 3OUT3 SHARK 282...

Page 90: ...MEP S p A 6 38 81 Use and maintenance manual SHARK 282 Fixed work table and turntable 282...

Page 92: ...MEP S p A 6 40 83 Use and maintenance manual SHARK 282 Optional Cut Control System...

Page 94: ...MEP S p A 6 42 85 Use and maintenance manual SHARK 282 Supplementary pneumatic vice 282...

Page 96: ......

Page 151: ......

Page 152: ......