MEP S.p.A.

3--4

14

Use and maintenance manual

SHARK 282

The operator must not perform any risky operations or operations not

required for the machining operation under way (e.g. remove swarf or

metal shavings from the machine while cutting).

Remove equipment, tools or any other objects from the cutting zone;

always keep the working area as clean as possible.

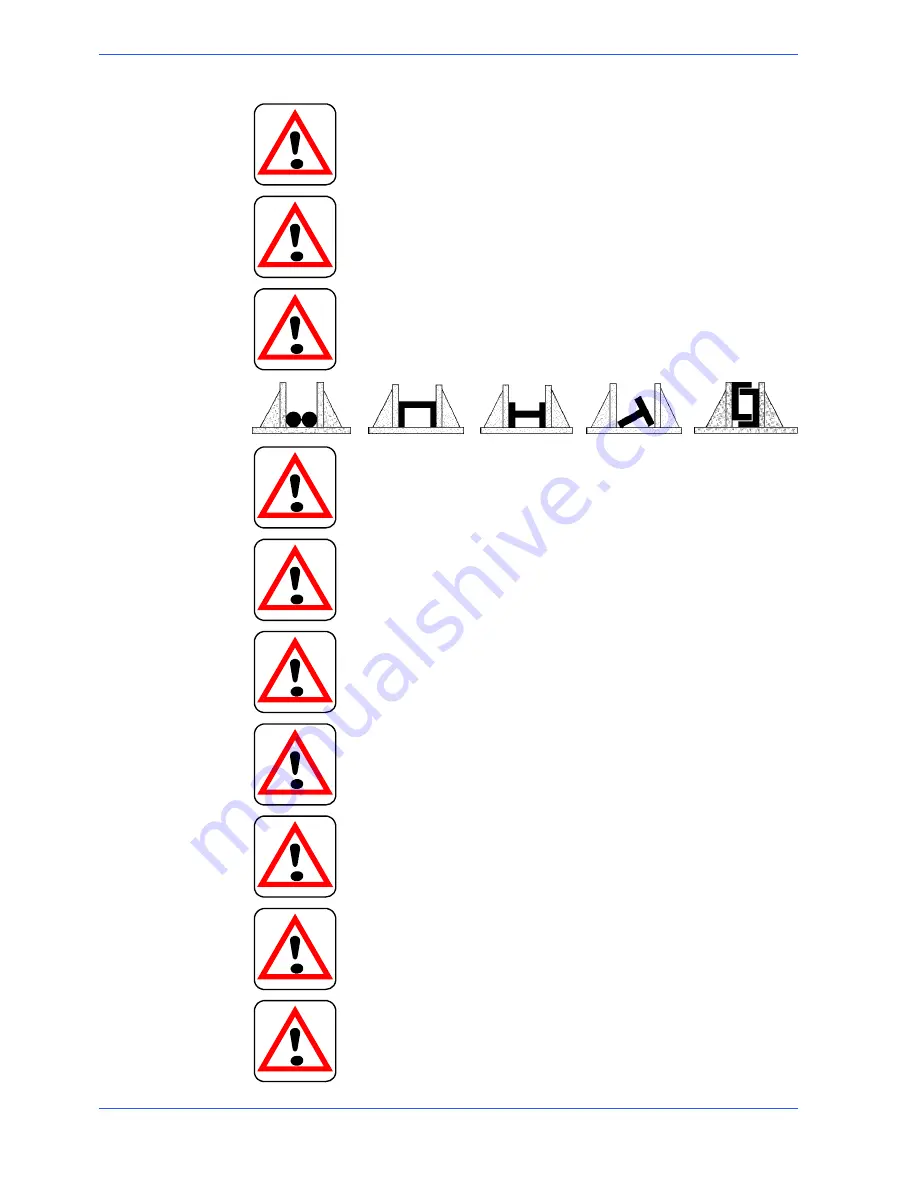

Before starting any cutting operations, ensure that the workpiece is

securely held in the vice and the machine has been set correctly. A

number of examples of how to clamp different profiles correctly in our

machines are shown below.

Do not use the machine to cut pieces that exceed the capacity of the

machine as listed in the machine specifications.

Never move the machine while it is cutting.

Do not use blades of different sizes to those recommended in the

machine specifications.

When cutting very short pieces, make sure that they are not dragged

behind the support shoulder, where they could jam in the blade.

When using the pneumatic vice (MA version) check that the jaws move

right up to and effectively clamp the workpiece, as the maximum travel is

only 8 mm, and check that the clamping procedure is correct.

When working on the band saw, wear gloves only when handling

materials and for tool changing or adjustment operations. Only perform

one operation at a time and do not hold more than one item or operate

more than one device simultaneously. Keep hands as clean as possible.

Warning: if the blade jams in the cut, press the emergency stop

push---button immediately. If this does not free the blade, slowly loosen

the vice, remove the piece and check the blade or blade teeth for

breakage. Replace the blade if necessary.

Summary of Contents for SHARK 282

Page 1: ...USE AND MAINTENANCE MANUAL YEAR OF MANUFACTURE ______________ SHARK 282 EN...

Page 2: ......

Page 4: ......

Page 8: ......

Page 59: ...6 7 51 Diagrams exploded views and replace Standardised Wiring Diagrams CENELEC Standard...

Page 60: ...MEP S p A 6 8 52 Use and maintenance manual SHARK 282...

Page 61: ...6 9 53 Diagrams exploded views and replace...

Page 62: ...MEP S p A 6 10 54 Use and maintenance manual SHARK 282...

Page 63: ...6 11 55 Diagrams exploded views and replace...

Page 64: ...MEP S p A 6 12 56 Use and maintenance manual SHARK 282...

Page 65: ...6 13 57 Diagrams exploded views and replace...

Page 66: ...MEP S p A 6 14 58 Use and maintenance manual SHARK 282...

Page 67: ...6 15 59 Diagrams exploded views and replace...

Page 68: ...MEP S p A 6 16 60 Use and maintenance manual SHARK 282...

Page 69: ...6 17 61 Diagrams exploded views and replace...

Page 70: ...MEP S p A 6 18 62 Use and maintenance manual SHARK 282...

Page 71: ...6 19 63 Diagrams exploded views and replace...

Page 72: ...MEP S p A 6 20 64 Use and maintenance manual SHARK 282...

Page 73: ......

Page 76: ...MEP S p A 6 24 67 Use and maintenance manual SHARK 282 Front flywheel assembly 282...

Page 78: ...MEP S p A 6 26 69 Use and maintenance manual SHARK 282 Motor flywheel assembly 282...

Page 80: ...MEP S p A 6 28 71 Use and maintenance manual SHARK 282 Cutting head cover 282...

Page 82: ...MEP S p A 6 30 73 Use and maintenance manual SHARK 282 Vice assembly 282...

Page 84: ...MEP S p A 6 32 75 Use and maintenance manual SHARK 282 Base assembly 282...

Page 86: ...MEP S p A 6 34 77 Use and maintenance manual SHARK 282 Control panel...

Page 88: ...MEP S p A 6 36 79 Use and maintenance manual SHARK 282 Handgrip 3OUT3 SHARK 282...

Page 90: ...MEP S p A 6 38 81 Use and maintenance manual SHARK 282 Fixed work table and turntable 282...

Page 92: ...MEP S p A 6 40 83 Use and maintenance manual SHARK 282 Optional Cut Control System...

Page 94: ...MEP S p A 6 42 85 Use and maintenance manual SHARK 282 Supplementary pneumatic vice 282...

Page 96: ......

Page 151: ......

Page 152: ......