Functional Description of EGM

_____________________________________________________________________

Status September 2003 (EvoBus-Service / AFT)

Page: 11 of 83

2

Functional Description of EGM

2.1

Introduction

The EGM (electric gas engine) engine control unit is mounted on the engine, and is therefore part of the

engine. Only one basic control unit is required for all offered output variants

1

of the M 447 hLAG. The

EGM is adapted to the corresponding output and engine variant with different programming. An EGM that

is already programmed is considered a special engine component and may not be interchanged between

different engines. An exchange of the EGM can lead to problems ranging from impairment of correct

engine operation to engine and drive train damage. Exchange engines are always delivered complete with

the engine wiring harness and the related EGM engine control

unit.

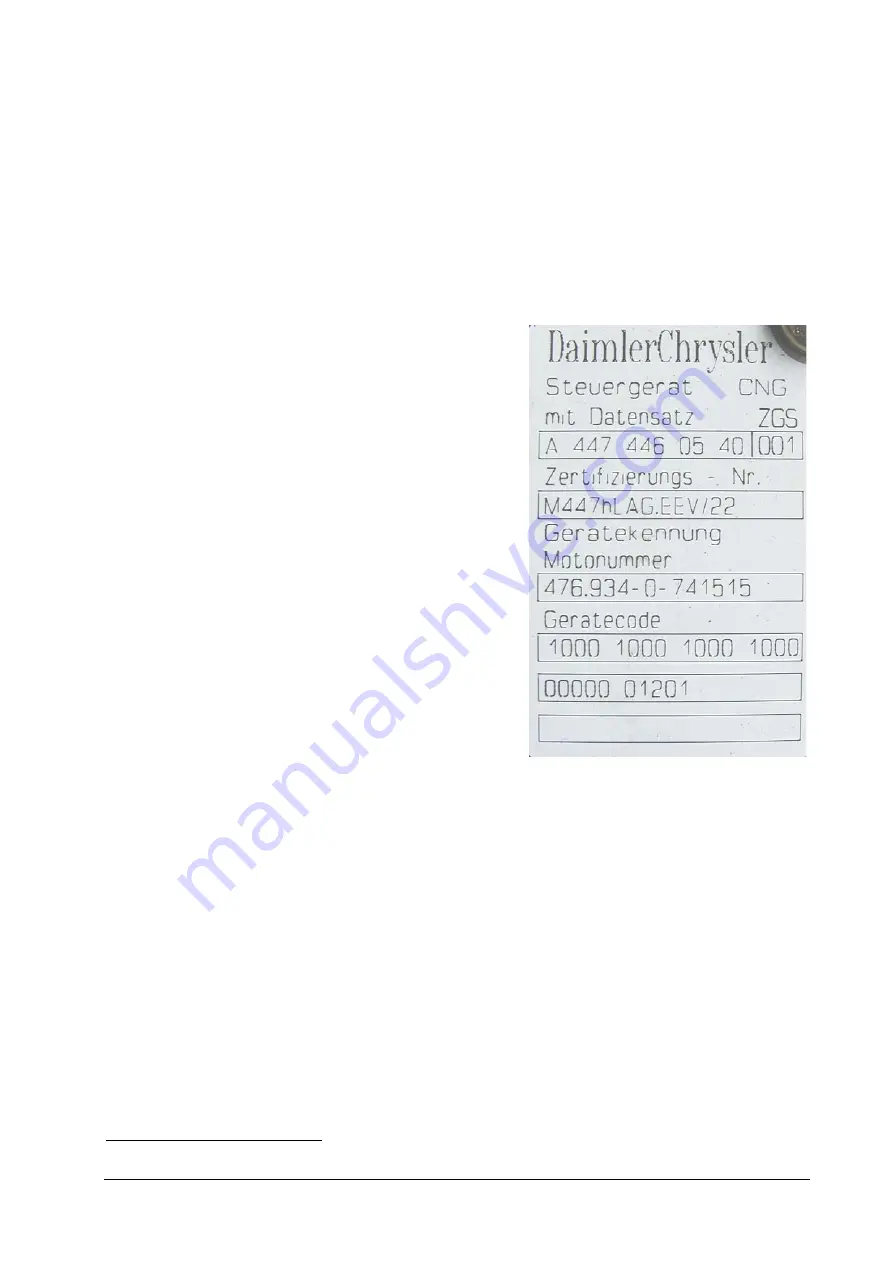

To be able to distinguish between different control units,

each unit is provided with a sticker. The data record number

(1) with which the EGM is programmed is indicated at the top

of the sticker. This data record number should always be

specified when purchasing a replacement.

The

EGM engine control unit is an electronic spark-

ignition engine control unit

for engines of the 447 and 900

series. The EGM's design is based on the PLD diesel engine

control unit and is virtually identical to the PLD on the

outside. Open and closed-loop control functions which can be

used both for diesel and spark-ignition engines have been

adopted from the PLD in the EGM. Examples include:

•

Engine control with torque interface

•

Camshaft/crankshaft signal detection

•

CAN and ISO-K interfaces

•

Oil level sensing

•

PIN assignment of vehicle connector

•

Service engine switch Start/Stop

•

Starter control

The functions specific to spark-ignition engines have been newly developed. The main open and closed-

loop control functions are:

•

Air mass control by electronic throttle valve and boost-pressure control

•

Dwell and firing-angle control

•

Sequential gas injection with variable start of gas injection

•

Lambda control with broadband probe for lambda = 1 and lean operation

•

Engine protection functions

•

Diagnostic functions

1

The output variants with 185 kW (rigid vehicle) and 240 kW (articulated vehicle) are currently available