Functional Description of EGM

_____________________________________________________________________

Status September 2003 (EvoBus-Service / AFT)

Page: 35 of 83

2.5

Gas injection

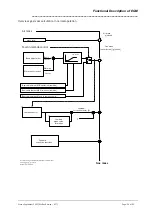

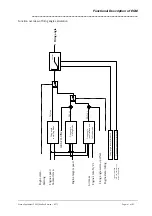

The fuel (here CNG) is injected by cylinder-selective actuation of the gas injectors following successful

crankshaft/camshaft synchronisation. The injectors are actuated in two phases. In the first phase, the so-

called push phase, the injectors are heavily charged with current to open them quickly and completely.

The push phase follows the hold phase in which the injectors are charged with less current to protect

them from overheating. The quantity of the injected fuel is proportional to the entire actuation time, the

injection time and/or the injection angle.

The injection time is calculated from the gas mass to be injected. The gas mass is determined time-

controlled in the starting mode and remains unaffected by the lambda control, while the determination of

the gas mass outside the starting mode is mainly based on the air mass and the other correction

functions such as warm-up correction etc.

2.5.1

Gas mass calculation during starting

The starting gas mass results from the basic injection mass, which is corrected during starting in

accordance with the existing basic conditions. The environmental influences starting temperature and

ambient pressure can each be taken into account accordingly in the forma of a characteristic curve. The

engine speed and ignition number can also be taken into account with a characteristic curve.

2.5.2

Gas mass calculation in normal case

The calculation of the gas mass to be injected outside of starting is mainly based on the air mass fed to

the engine, the stoichiometric mass ratio of air and the natural gas used and the lambda target value. In

addition, the gas mass based on the variables previously named is charged as needed with warm-up and

dynamic enrichment.

•

Mass ratio

The mass ratio corresponds to the quotients of air mass and gas mass for stoichiometric operation

(lambda = 1). The mass ratio can be subject to large fluctuations depending on the natural gas used.

From software version 14A these fluctuations are taken into account via the formation of a mean value

of the lambda correction factor when calculating the gas mass.

•

Basic adjustment

In the basic adjustment maps the lambda target value is defined as a function of the air mass and the

engine speed dependent on the operating point. The basic adjustment factor is used to calculate the

gas mass as the target value specification.

•

Warm-up correction

The warm-up correction enables special enrichment to be carried out for the warm-up mode. This

permits improved engine operation and provides for higher exhaust-gas temperatures to shorten the

warm-up phase. The intensity of the warm-up correction is dependent on the coolant temperature. The

warm-up correction is completed when the coolant temperature has reached approx. 35 °C.

•

Lambda control

The target value for the lambda control is the basic adjustment factor. The gas mass is corrected with

the lambda correction factor in dependence on the lambda target-actual difference.

•

Dynamic gas enrichment

An additional gas mass enrichment is required in dynamic engine operating states. Several functions

are realised in the EGM for this purpose.

•

Gas quality detection

From software version 14A a gas quality detection function is realised to adapt the lambda target

value and the firing angle to the special requirements of high gas. A change in the gas quality can be

detected by means of a mean value formation of the lambda correction factor.