Electrical Description of EGM

Status September 2003 (EvoBus-Service / AFT)

Page: 49 of 83

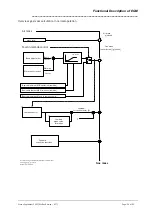

3.2.3.2

Camshaft/crankshaft position (inductive)

To detect and evaluate the current crank angle and speed of the engine, one inductive sensor (e.g. VDO)

each is used to generate the camshaft and crankshaft signals.

Inductive sensor data:

L in mH

R in

Ω

630 ±15 %

1000.....1385

3.3

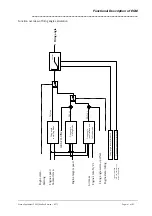

Digital inputs

The EGM engine control unit is equipped with the following digital inputs:

Terminal 15, Terminal 50 and engine Start/Stop.

3.3.1

Terminal 15

By connecting the Terminal 15 voltage (Terminal 15 ON), the engine control unit is woken up and runs up.

This voltage is converted by a comparator into a digital signal and this signal is read in by the processor.

The function software of the engine control unit operates using this Terminal

15 signal from the comparator and the Terminal 15 signal which arrives via the CAN bus.

The switching thresholds for reliable detection of the Terminal 15 voltage on connector pin 15 of the 16-

pin engine connector are:

Control Unit Version

Terminal 15 ON

Terminal 15 OFF

24 V

>

11.3 V

<

6 V

3.3.2

Terminal 50

With Terminal 50 ON the transponder code for the immobiliser (if installed) is read in and the starter

starting signal is output with a valid code.

The switching thresholds for reliable detection of the Terminal 50 voltage on connector pin 8 of the 16-

pin engine connector are:

Control Unit Version

Terminal 50 ON

Terminal 50 OFF

24 V

>

7.8 V

<

2.6 V

The switching threshold for waking up the control unit via Terminal 50 is 9 V.

3.3.3

Service switch Start/Stop

Two digital inputs (short-circuit-proof to earth) are provided which enable the functions

Service switch

Start

and

Stop

by means of service buttons installed on the engine. An engine start by the Service button

is only possible in conjunction with the vehicle electronics, and therefore only in the vehicle. The buttons

are supplied with a voltage of approx. 5 V.