P 8

Please retain product label and instructions for future reference

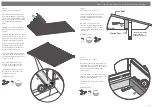

Step 12

Parts Needed - No. 19 QTY 72

Place the first two roof boards

(No. 19) onto the assembly on

each side, making sure the boards

are flush to the end of the roof

purlin. Once in position fix to each

purlin using 3x40mm screws.

*Ensure the roof boards meet

at the top of the apex and leave

an overhang at the bottom.

Due to natural occurences of wood

shrinkage / expansion. You may be

required to use the provided spacers

and place a space of 2mm to ensure

every roof board lines up with the

truss’.

Continue adding the roof boards

along the roof, fixing each one into

position using 3x40mm screws,

making sure that each board is

interlocked, flush at the bottom &

meet at the top of the apex.

The last board on each side will

overhang: Using a straight edge

and a pencil mark out a line as

a guide.

Cut along the pencil mark and

remove the excess. Place the

cut down boards back onto the

roof and secure into place

using 3x40mm screws per

board.

*Please Note:

This image is for illustrative

purposes and may differ from your choice in

product. Nevertheless the process of cutting

and fitting the last roof boards is the same.

216 x40mm Screws

40mm

screw

Pre drill

hole

*

Cut to fit

19

19

19

18

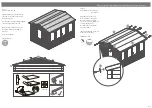

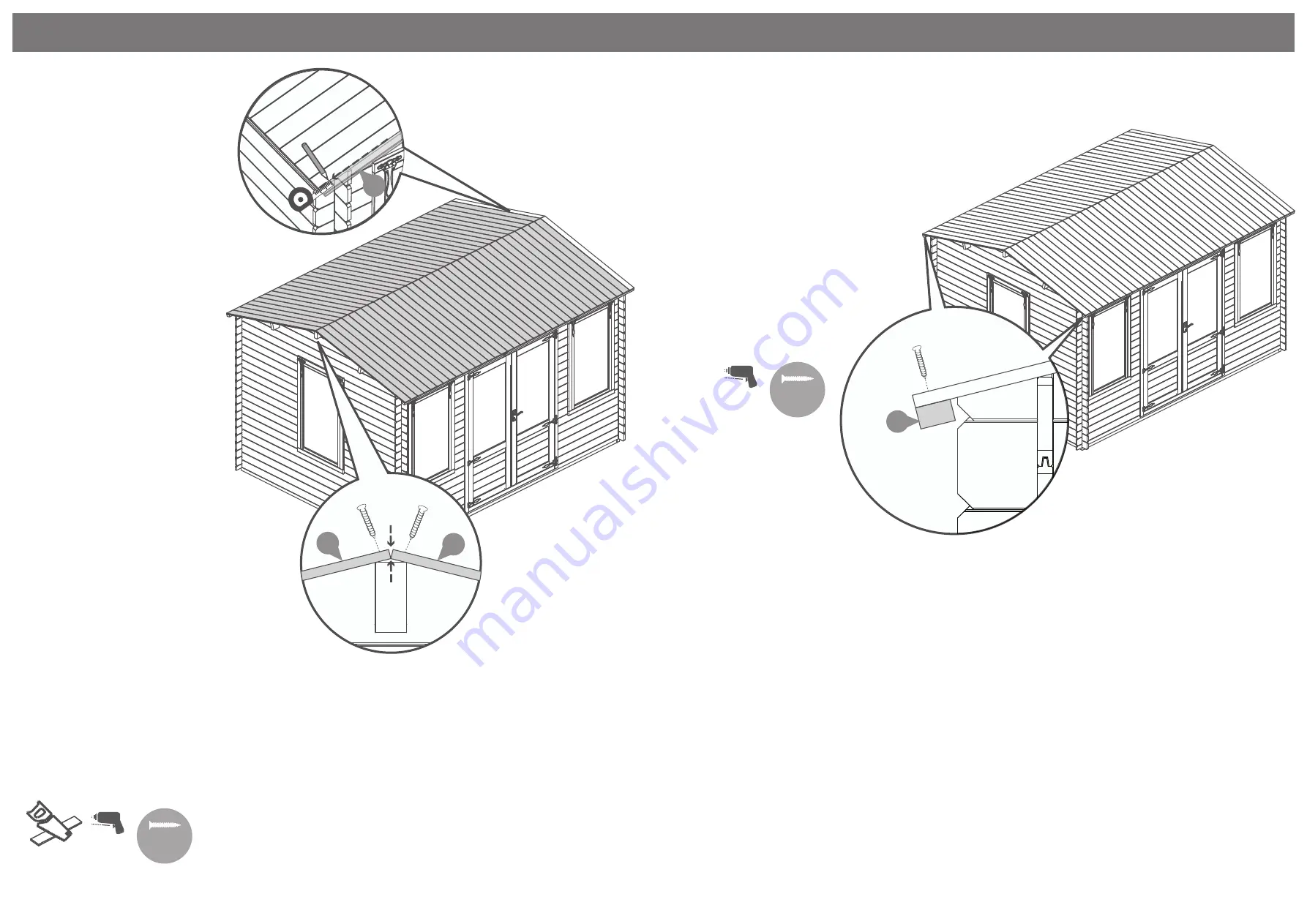

Step 13

Parts Needed - No. 18 QTY 2

Ensuring the roof boards are flush

at the overhanging side and meet

at the apex, fix the eaves frames

(No. 18) to the underside of the roof

boards using 9x40mm screws as

shown in the illustration

*Please Note:

This image is for

illustrative purposes and may

differ from your choice in

product. Nevertheless the process

of fixing the eaves frames is the

same.

18x40mm Screws

40mm

screw

Pre drill

hole