P 10

Please retain product label and instructions for future reference

Felt tacks

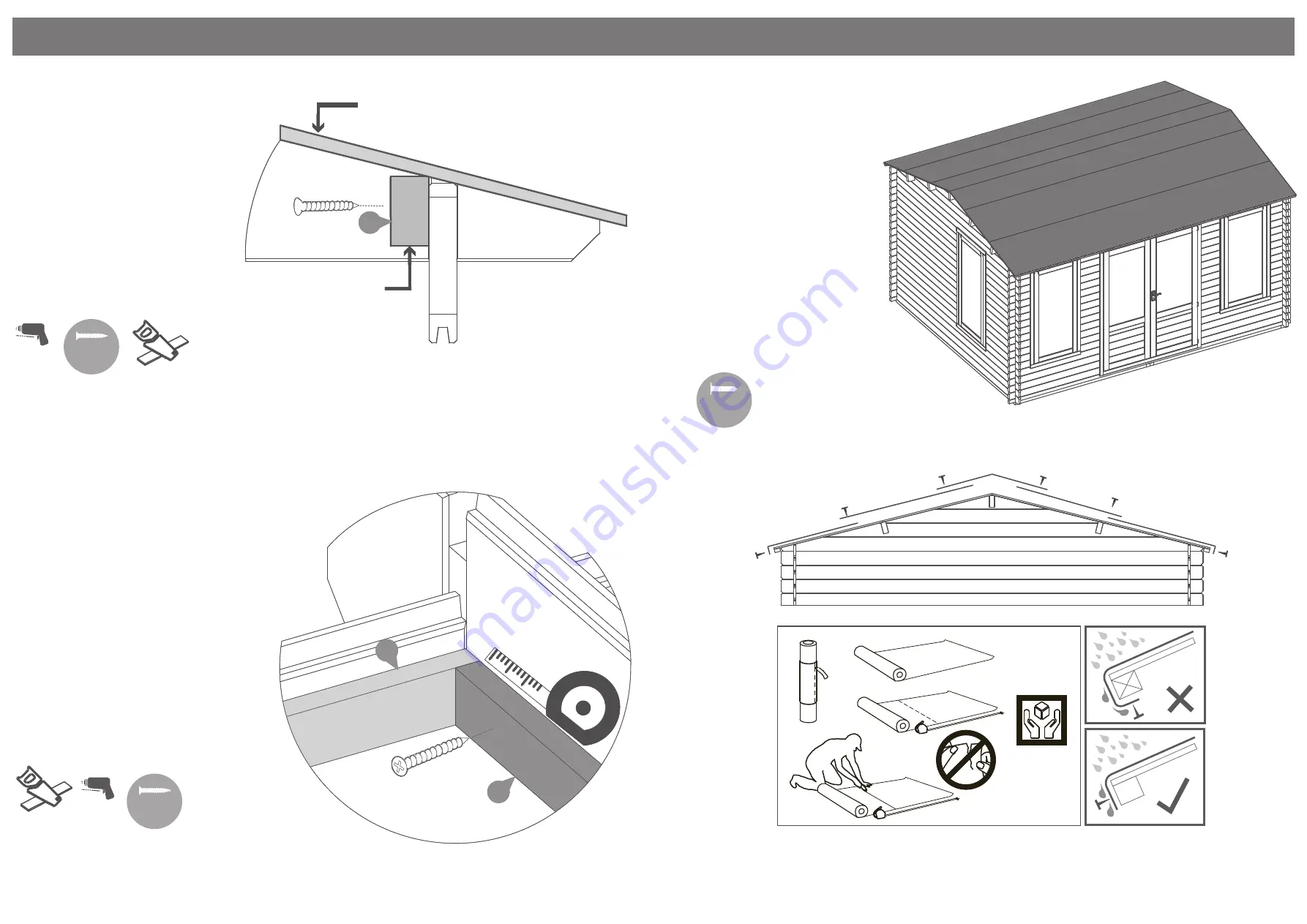

Step 17

Parts needed - No. 24

Cut the felt

(No. 24)

into five strips &

lay onto the roof in the order shown

in the illustration.

*Ensure there is approximately

50mm of overhanging felt each

side.

Once the felt is laid out fix to the

roof using felt tacks at 100mm

intervals.

*Felt size: 5132mm

416x Felt Tacks

HANDLE

WITH CARE

1

2

3

4

1.

2.

3.

4.

5.

Roof

Closure Trim

Internal

23

*Measure and cut the

closure trims to

fit the internal space.

23

23

Roof

Closure Trim

Internal

23

*Measure and cut the

closure trims to

fit the internal space.

23

23

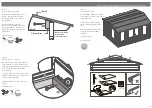

Pre drill

hole

30mm

screw

*

trim to fit

Step 15

Parts needed - No. 23 QTY 6

Inside the building place the closure

trim (

No. 23

) against the boarding

and align with the roof as shown in

the illustration.

Once in position fix each trim

into place by pre drilling a pilot hole

and using 6x30mm screws per trim,

equally spacing them along the face

of the board.

36x30mm Screws

30mm

screw

Pre drill

hole

*

Cut to fit

Step 16

Parts needed - No. 23 QTY 7

Once the floor has been laid arrange the

closure trim (

No. 23

) around the outside

edge of floor (

internally

), measure and cut

down accordingly to best match the

internal space.

Secure each trim section into place using

6x30mm spaced equally along the board

as shown in the illustration.

*Do NOT fix the closure trim to the floor

boards.

42x30mm Screws