Cleaning and Sterilizing

Procedures

Cleaning in Place (CIP)

GMP mixers are designed for CIP using any

of the following processes: sprayball, rotary

jethead, or submerged.

Sprayball and Rotary Jethead Cleaning

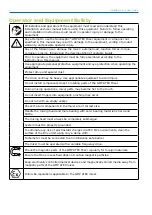

!

Start the liquid circulation through

the sprayball or jethead before

starting the mixer to ensure

lubrication of the bearing.

Ensure that the bearings are

continuously lubricated.

Stop the mixer before turning off

the sprayball/jethead function.

Add liquid before running the

mixer after cleaning to ensure

lubrication of the bearings.

NOTE

Recommended maximum speed of

the mixing head is 100 rpm.

Submerged Cleaning

Introduce enough cleaning or rinsing liquid into

the vessel to cover the mixing head and the

male bearing.

NOTE:

Avoid vortex.

Add liquid before running the mixer

after cleaning to ensure lubrication of

the bearings.

Magnetic Particles:

If presence of magnetic particles is

suspected, remove the mixing head.

Remove the particles and reinstall the

mixing head. (Refer to Male Bearing

Installation, Mixing Head Installation,

and Drive Unit Installation in this

manual.)

Magnetic particles are not removed

from the mixing head during CIP;

they must be removed manually or by

alternative cleaning. Magnetic particles

can cause corrosion and damage. They

can also cause a higher torque, which

may cause the mixing head to decouple

and severely damage the vessel.

Sterilizing in Place (SIP)

GMP mixers are designed for SIP.

Sterilization by Pressurized Steam

The mixer can be intermittently operated

during the initial condensate phase of the

sterilization sequence up to 100 °C (212 °F).

Recommended maximum speed of the mixing

head is 50 rpm for no longer than 30 seconds.

NOTE

Ensure that condensate lubricates the

bearing surfaces.

Recommended maximum speed of the

mixing head during sterilization is 50 rpm.

Turn the mixer off when the

temperature reaches 100 °C (212 °F).

Add liquid before restarting the mixer

after sterilization to secure lubrication

of the bearings.

Magnetic Particles

If presence of magnetic particles is

suspected, remove the mixing head.

Remove the particles and reinstall the

mixing head. (Refer to Male Bearing

Installation, Mixing Head Installation,

and Drive Head Installation in this

manual.)

Magnetic particles are not removed

NovAseptic

®

GMP ATEX Mixer

17

Summary of Contents for EMD Millipore NovAseptic

Page 2: ...2 Installation and User Guide ...

Page 4: ...4 Installation and User Guide ...

Page 31: ...NovAseptic GMP ATEX Mixer 31 ...