EXi-F

positive pressure smoke control system

„MERCOR” S.A. –

Specifications are subject to change without notice. Version DTR_EXIF_EN_20220516

Page

10

/ 28

The automatics used in mcr Omega unit control, supply, monitor and visualize operation of all

mcr EXi-F kit components.

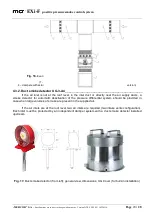

Fig. 6.

mcr Omega control unit - general view

Main control unit (CU) tasks:

power supply, control and monitoring of the air supply fans for positive pressure via signals from

the fire alarm control panel (FACP),

power supply, control and monitoring of the air control and shut-off dampers, unit maintain

dumpers power supply

power supply and operation of the duct smoke detector (used optionally).

power supply, control and monitoring of dampers used in differential pressure system.

The control unit is supplied with 3 x 400 V. The control unit is powered by an incoming panel for

fire protection equipment, which is not being disconnected with a fire switch or is equipped with an

automatic reserve power switch (ARPS) in buildings, where no incoming panel for fire protection

equipment is available in the main switchboard.

mcr Omega control unit is delivered in powder coated on stainless steel enclosure with front

door and IP55 protection rating (external and internal version available). The door is fitted with a

gasket, lock or rotary lock with a key. Depending on its version, a cover with cable glands is available

at the top or at the bottom of the device. The number and location of cable glands depend on the

system size and the number of controlled and supplied external devices. The device dimensions vary

from 300 x 200 x 150 mm to 1200 x 2000 x 300 mm depending on the number of controlled devices

and the complexity of operations and switching program. A visualization panel with FACP power

supply, alarm and failure indicators is mounted on the door.