EXi-F

positive pressure smoke control system

„MERCOR” S.A. –

Specifications are subject to change without notice. Version DTR_EXIF_EN_20220516

Page

24

/ 28

Note:

Do not use the service switch during air supply unit operation.

Using the service switch during air supply unit operation will damage the speed regulator of the Omega

control supply unit.

5.3.

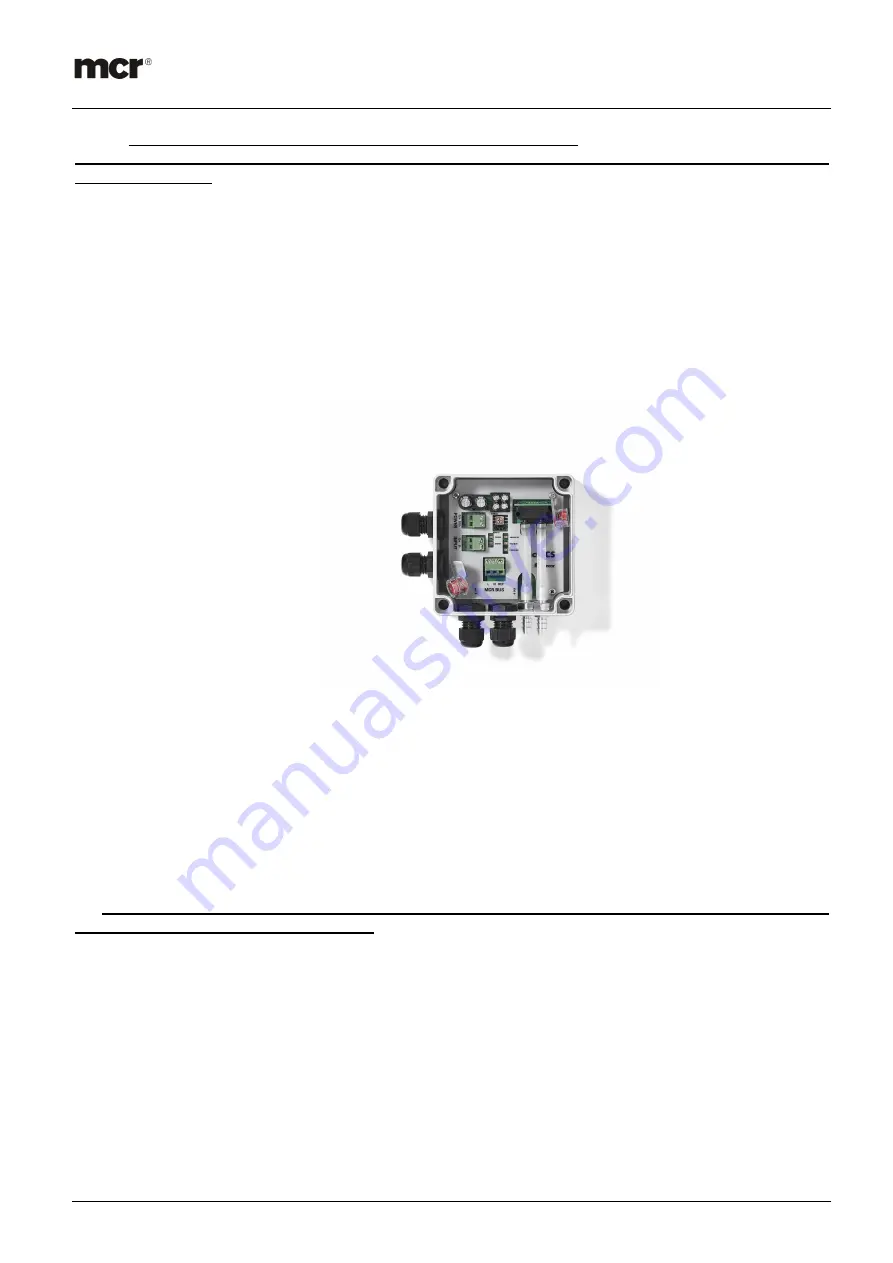

mcr ICS pressure transmitters

5.3.1 mcr ICS digital pressure transmitter

The pressure source is connected via a flexible 8 mm dia. pressure line (2 m pressure line

included with the pressure transmitter), power supply

24 [V], AC/DC (connected to mcr ICR

installed on mcr Omega unit)

. Data transmitted via mcr BUS protocol. Number and type of cables

required for mcr ICS connection, see Table 6.

Fig. 21.

mcr ICS transmitter terminals view

Protected lobby protection.

mcr ICS digital pressure transmitters connected to mcr Omega control supply unit are installed

in the protected lobbies. A fire signal for a specific floor is provided for each controller. In case of a fire,

mcr ICS assigned to a specific floor is activated. The pressure is adjusted based on the read-outs from

the activated mcr ICS pressure transmitter.

Note:

Pressure line connection polarity does not affect measurement accuracy, since each regulator

responds to the absolute measurements.

Pressure system outside the building should be made with silicone pressure lines (resistant to

low temperature). Protect the ends of the hydraulic lines against accidental blocking. Use outlet boxes

included with mcr ICS pressure transmitter.

Follow the instructions for installation of pressure lines. The pressure lines must be installed with

a gradient from mcr ICS pressure transmitter to the outlet box, avoiding flow restrictions. Use fittings

and lead the pressure line in the RL type conduits, flush or surface-mounted, as an additional

protection against mechanical damage.