EXi-F

positive pressure smoke control system

„MERCOR” S.A. –

Specifications are subject to change without notice. Version DTR_EXIF_EN_20220516

Page

5

/ 28

3.2.

Operation

______________________________________________________

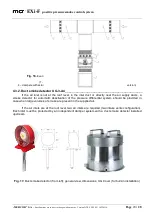

The system is managed by mcr Omega control unit (CU) including all the required components

(e.g. mcr ICR positive pressure regulator). Positive-pressure mcr EXi-F system is activated

automatically via SAP signal or manually via CU or the manual control panel. After detecting the fire in

the building, the air dampers of the air supply units are activated, and the air supply unit is activated

with a delay (necessary to open the shut-off dampers). After several seconds, the protected area is

filled with air to create the differential pressure between the protected area and the adjacent areas.

The required positive pressure is controlled by a variable air volume supplied to the protected

area by the air supply unit(s). Provided that the door to the protected area are closed, the main fan of

the air supply unit maintains a stable positive pressure. The actual pressure in the protected area is

measured and controlled by mcr ICS. The positive pressure in the staircase (20-80 [Pa]) guarantees

that the force required to open the exit door does not exceed 100 [N]. Opening the door results in

pressure drop in the protected area, thus increasing the fan speed and providing the design air flow

rate through the door separating protected and non-protected areas.

For the air flow rate to reach the required value, air relief is provided using one or more of the

following:

- opening in the external wall (e.g. automatically doors – mcr OSO system, grilles),

- vertical air vent shaft with vents in the adjacent areas (e.g. mcr FID S, mcr WIP, mcr WIP PRO)

are connected to the common vertical shaft for discharging the smoke at the top of the building,

- mechanical exhaust with a proper design and control system.