© 2010 Mercury Marine

3.0L TKS Alpha Models

*8M0053263*

90-8M0053263 1110

NOTE: The following applies to CE marked products only.

Declaration of Conformance – Mercury MerCruiser

This sterndrive or inboard engine when installed in accordance to Mercury MerCruisers’ instructions complies with the

requirements of the following directives by meeting the associated standards, as amended:

Recreational Craft Directive 94/25/EC; 2003/44/EC

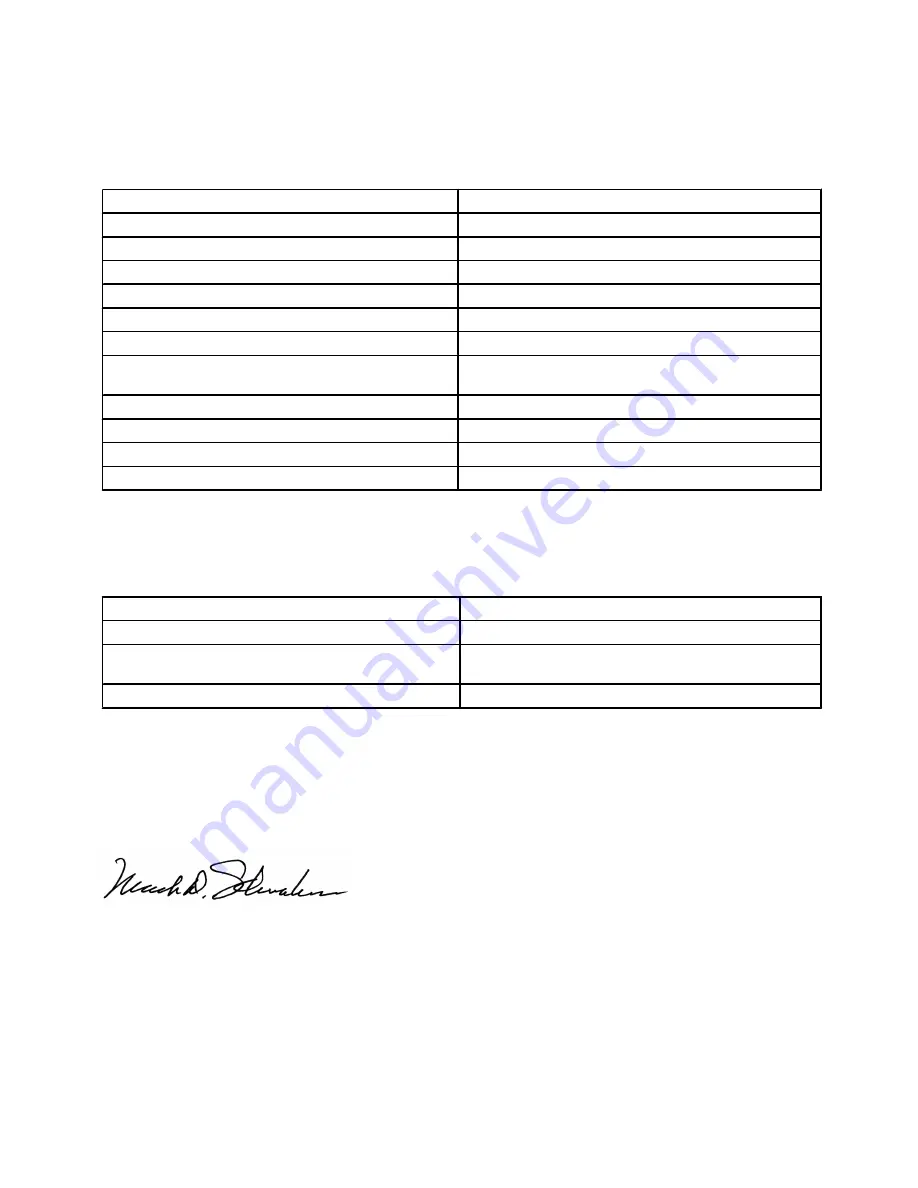

Applicable Requirement

Standards Applied

Owner’s manual (A.2.5)

ISO 10240

Openings in Hull, Deck and superstructure (A.3.4)

ISO 9093‑1; ISO 9093‑2

Handling characteristics (A.4)

ISO 8665

Inboard Engine (A.5.1.1)

ISO 15584; ISO 10088; ISO 7840; ISO 10133

Fuel System (A.5.2)

ISO 10088; ISO 7840; ISO 8469

Electrical System (A.5.3)

ISO 10133; ISO 8846

Steering system (A.5.4)

Applicable portions of: ISO 10592, ISO 8848 and ABYC

P‑17

Exhaust emission requirements (B.2)

ISO 8178

Owner’s manual (B.4)

ISO 8665

Noise emission levels (C.1)

ISO 14509

Ignition‑protected equipment (Annex II)

ISO 8846; SAE J1171; SAE J1191; SAE J 2031

Mercury MerCruiser declares that our sterndrive or inboard engines without integral exhaust, when installed in a

recreational craft, in accordance with the manufacturers supplied instructions, will meet the exhaust emissions

requirements of the directive mentioned above. This engine must not be put into service until the recreational craft in which

it is to be installed has been declared in conformity, if so required, with the relevant provision of the directive.

Electromagnetic Compatibility Directive 89/336/EC, 92/31/EEC and 93/68/EEC

Generic emission standard

EN 50081‑1

Generic immunity standard

EN 50082‑1

Vehicles, boats and internal combustion engine driven

devices ‑ Radio disturbance characteristics

SAE J551 (CISPR 12)

Electrostatic discharge testing

EN 61000‑6‑2; EN 61000‑4‑2; EN61000‑4‑3

The notified body responsible for surveillance of the quality system under Full Quality Assurance Module H of Directive

2003/44/EC is:

Det Norske Veritas

Norway

Notified Body Number: 0575

This declaration is issued under the sole responsibility of Mercury Marine and Mercury MerCruiser.

Kevin Grodzki

President ‑ Mercury MerCruiser, Stillwater, OK, USA

Regulatory contact:

Regulations and Product Safety Department

Mercury Marine

W6250 W. Pioneer Road

Fond du Lac, WI 54936

USA

Identification Record

Please record the following information: