MCM MODELS

SERVICE MANUAL NUMBER 24

Page 2A-2

90-861327--1 OCTOBER 1999

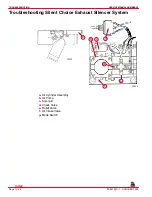

Torque Specifications

Fastener Location

lb-in.

lb-ft

Nm

Cable Barrel

Spread Cotter Key

Drive Unit Shift

Cable

Cable End

Guide

See Note

Hose Clamps

Securely

Rear Engine Mounts

37

50

Power Steering Fluid Hose Fitting

23

31

Cable Barrel

Securely

Remote Control

Shift Cables

Cable End

Guide

See Note

Cable Barrel

Securely

Remote Control

Throttle Cable

Cable End

Guide

See Note

Drive Shaft

50

68

Extension Housing To Flywheel

Housing

30

41

Flywheel Housing

30

41

Front and Rear Engine Mounts

Battery Cables

Securely

Rear Engine Mount Bracket

50

68

NOTE: Tighten, then loosen 1/2 turn.

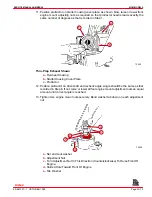

Tools

Description

Part Number

Engine Alignment Tool

91-805475A1

Universal Protractor

Obtain Locally

Lubricants / Sealants / Adhesives

Description

Part Number

Engine Coupler Spline Grease

91-816391A4

Quicksilver Liquid Neoprene

92-25711--3

Quicksilver 2-4-C Marine Lubricant With Teflon

92-825407A3

Loctite Pipe Sealant With Teflon

Obtain Locally

U-Joint and Gimbal Bearing Grease

92-828052A2

Loctite 27131

92-809820

Index