5.0l / 305 cid / 5.7l / 350 cid ENGINES

SERVICE MANUAL NUMBER 24

Page 3A-64

90-861327--1 OCTOBER 1999

Connecting Rod Bearings

Connecting rod bearings are of the precision insert type and do not use shims for adjust-

ment. DO NOT FILE RODS OR ROD CAPS. If clearances are found to be excessive, a new

bearing will be required. Service bearings are available in standard size and .001 in. and

.002 in. undersize for use with new and used standard size crankshafts. They are also avail-

able in .010 in. and .020 in. undersize for use with reconditioned crankshafts.

When removing a connecting rod cap, you may find a .010 in. undersize bearing. These are

used in manufacturing for selective fitting.

Inspection and Replacement

IMPORTANT: Before you remove the connecting rod cap, mark the side of the rod and

cap with the cylinder number to assure matched reassembly of rod and cap.

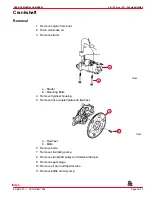

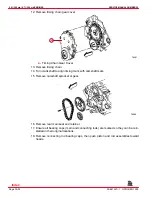

1. Remove oil pan and oil pump.

2. Remove connecting rod cap and bearing.

3. Inspect bearing for evidence of wear and damage. Do not reinstall a worn or damaged

bearing.

4. Wipe both upper and lower bearing shells and crankpin clean of oil.

5. Measure the crankpin for out-of-round or taper with a micrometer.

a. Not within specifications, replace or recondition the crankshaft.

b. Within specifications and a new bearing is to be installed, measure the maximum

diameter of the crankpin to determine required bearing size.

NOTE: If within specifications, measure new or used bearing clearances with gauging plas-

tic or its equivalent. If a bearing is being fitted to an out-of-round crankpin, be sure to fit to

the maximum diameter of the crankpin. If the bearing is fitted to the minimum diameter, and

the crankpin is out of round .001 in., interference between the bearing and crankpin will re-

sult in rapid bearing failure.

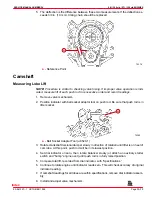

6. Measure bearing clearances.

a. Place a piece of gauging plastic, the length of the bearing (parallel to the crankshaft),

on the crankpin or bearing surface as shown.

b. Position the gauging plastic in the middle of the bearing shell. Bearings are eccentric

and false readings could occur if placed elsewhere.

72361

a

a -

Gauging Plastic

Index