IGNITION SYSTEM

SERVICE MANUAL NUMBER 24

90-861327--1 OCTOBER 1999

Page 4B-7

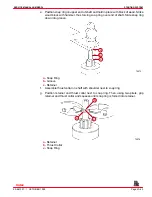

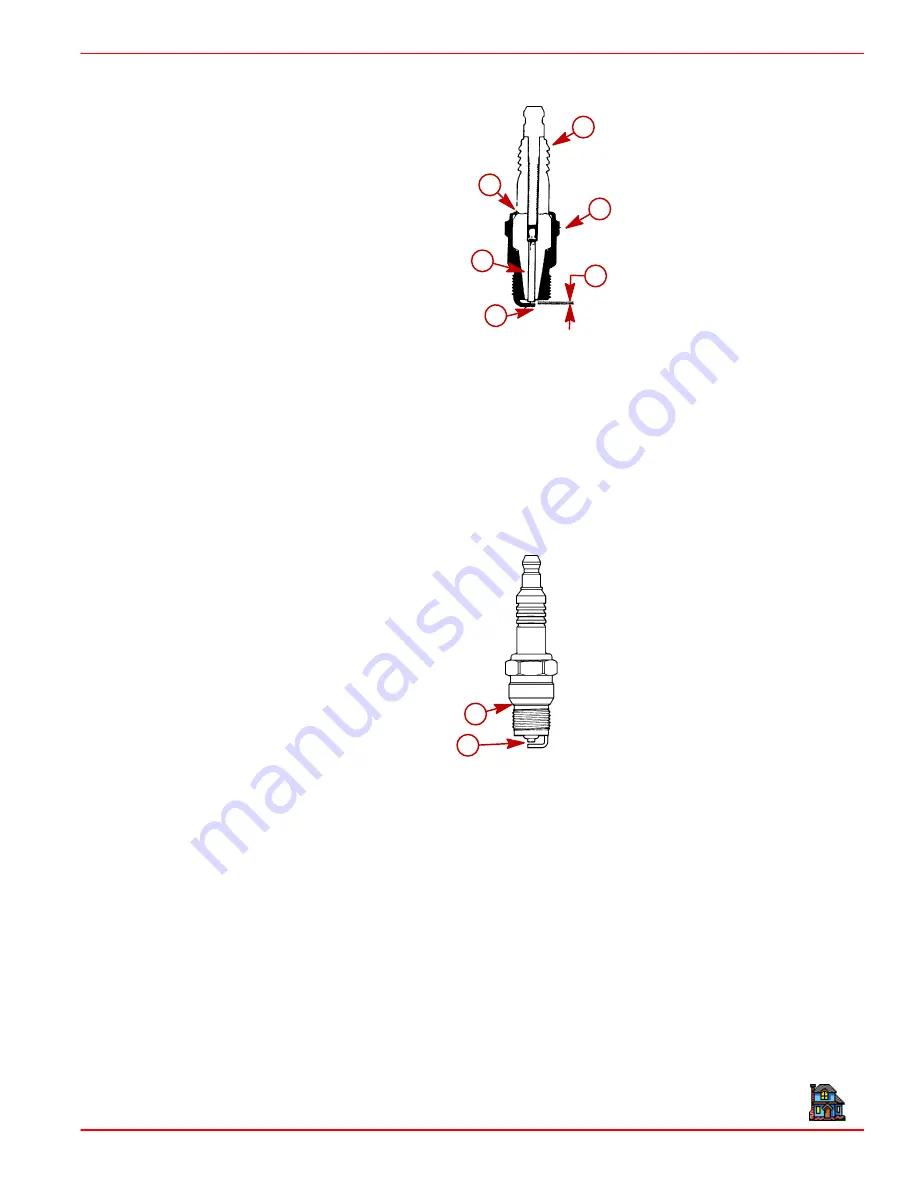

2. Inspect each plug individually for badly worn electrodes, glazed, broken or blistered

porcelain and replace where necessary.

72734

a

b

c

d

e

f

a -

Porcelain Insulator

b -

Insulator - Cracks Often Occur at This Point

c -

Shell

d -

Proper Gap

e -

Side Electrode

f -

Center Electrode (When Adjusting Gap - DO NOT Bend)

Replacing

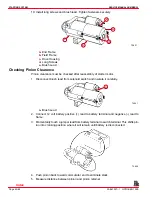

1. Clean the plug seating area on the cylinder heads.

2. Adjust spark plug gap with a round feeler gauge. Bend side electrode to adjust gap.

Refer to SECTION 1B – “Specifications” for correct spark plug gap.

75084

a

b

a -

Seating Area

b -

Gap

IMPORTANT: It is recommended that spark plugs be torqued to the amount specified.

In the absence of a torque wrench or access problems to the plugs, the spark plugs

should be hand tightened until the plug seats on the cylinder head. Then, securely

tighten with appropriate wrench and socket.

3. Install spark plugs and torque to specifications. Refer to “Torque Specifications,” in this

section.

4. Install spark plug wires in proper order. Refer to “Engine Rotation and Firing Order”

and/or “Spark Plug Wires,” following.

Index