IGNITION SYSTEM

SERVICE MANUAL NUMBER 24

Page 4B-8

90-861327--1 OCTOBER 1999

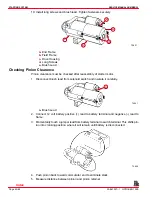

Spark Plug Wires

IMPORTANT: Proper positioning in spark plug wire supports is important to prevent

cross-firing.

Inspection

1. Visually inspect spark plug wires and coil wire for damage, such as cracks.

2. Visually inspect spark plug boots for damage.

NOTE: Use care when removing spark plug wires and boots from spark plugs. Twist the boot

1/2 turn before removing. Firmly grasp and pull on the boot to remove the wire end.

3. Check spark plug wires and coil wire for continuity using a Multi-Meter, Digital/Volt/Ohm

Meter, or similar. Replace any wires that do not show continuity from end to end.

4. Replace any damaged wires.

Replacing

IMPORTANT: Proper positioning of each spark plug wire is important to prevent

cross-firing.

IMPORTANT: Use only spark plug wires recommended for Marine application.

NOTE: When replacing spark plug wires, replace one wire at a time to reduce the risk of

error.

1. Disconnect individual spark plug wires.

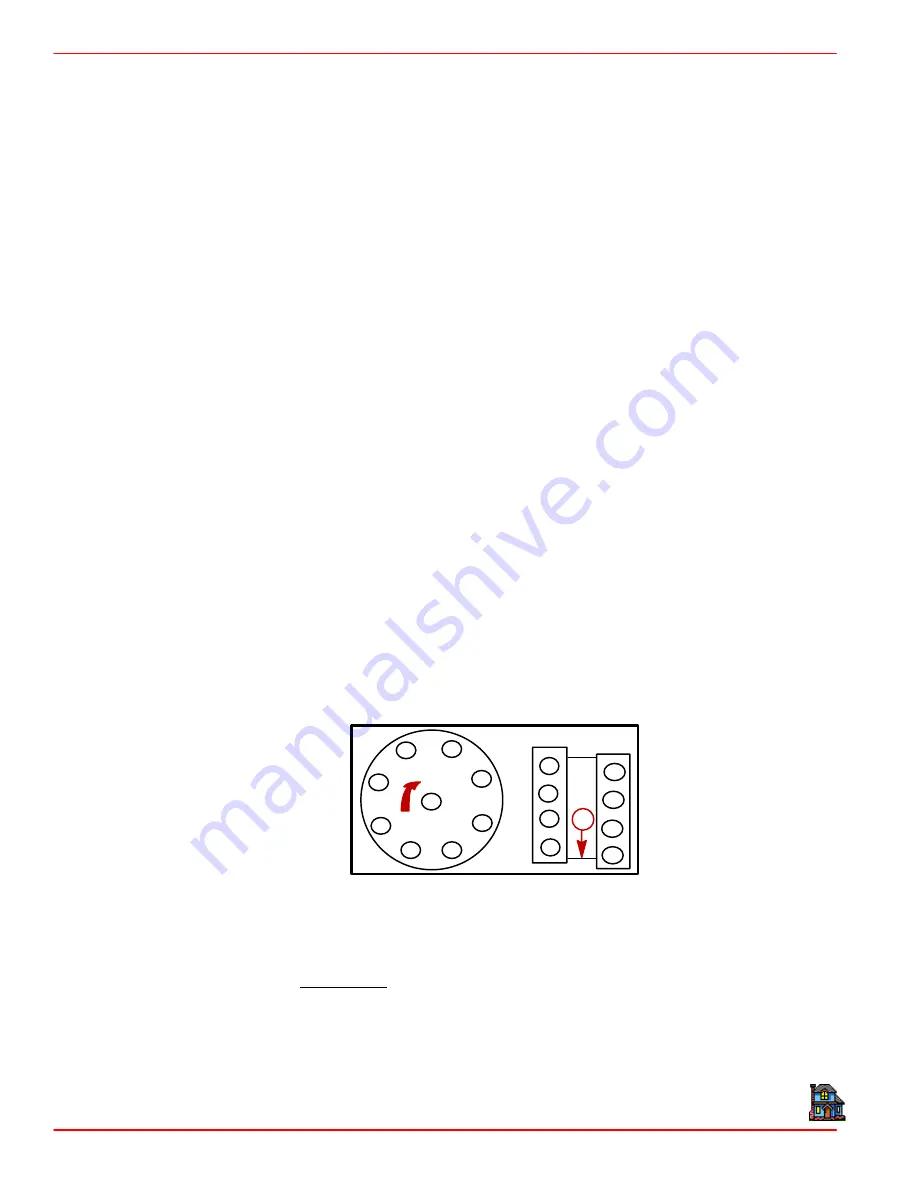

2. Install spark plug wires in proper order. Observe the following:

IMPORTANT: When replacing plug wires, route the wires correctly through the proper

supports. Correct positioning of spark plug wires and supports is important to

prevent cross-firing.

a. Position wires in spark plug wire supports and retainers, as provided.

b. Attach plug wires to appropriate spark plug and terminal on distributor cap. Each end

should fit securely.

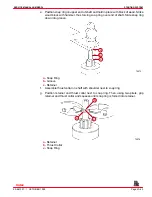

1

8

4

3

6

5

7

2

1

3

5

7

2

4

6

8

a

Rotor Rotation On LH Engine

a -

Front

IMPORTANT: Mercury Marine Coil Only, before installing coil wire (high tension lead)

to coil, apply approximately 1/2 oz. of Silicone Dielectric Compound (Quicksilver

92-802882A1) around top of coil high tension lead tower. Do not apply to inside of

tower hole.

c. Apply Silicone Dielectric Compound. Attach coil wire (high tension lead) to center

terminal on distributor cap.

Index