CHARGING SYSTEM

SERVICE MANUAL NUMBER 24

90-861327--1 OCTOBER 1999

Page 4C-13

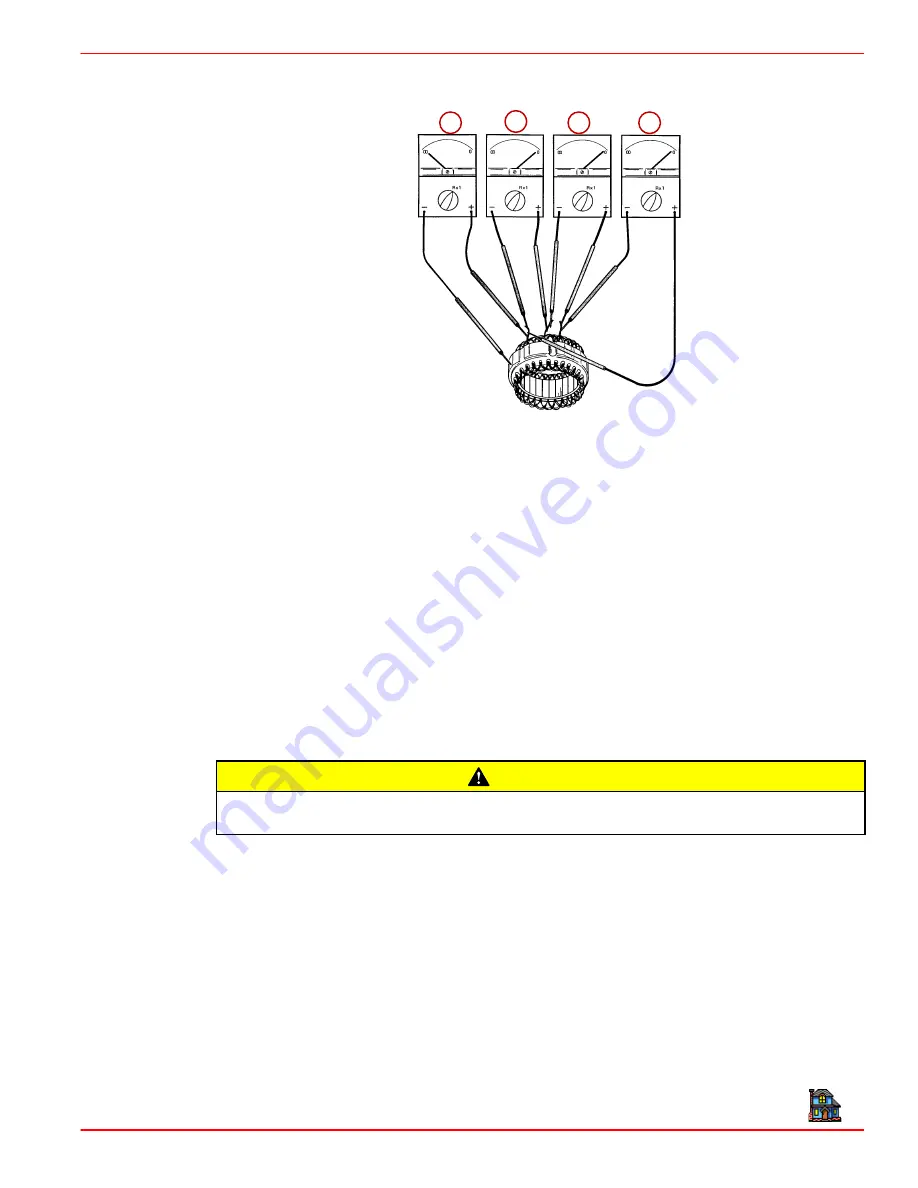

b. Continuity should be present in all three cases (meter should move). If it does not,

one or more of the windings are open and stator must be replaced.

72833

a

b

b

b

Testing Stator

a -

Test 1

b -

Test 2

3. A short in the stator is difficult to detect without special equipment, because of the low

windings resistance. If all other electrical components test out good, and alternator fails

to produce rated output, stator probably is shorted and should be replaced. Also,

examine stator for heat discoloration, as this usually is a sure sign of a short.

RECTIFIER AND DIODE ASSEMBLY

NOTE: Failure of any component in tests following will require replacement of entire rectifier

assembly.

NEGATIVE (–) RECTIFIER

IMPORTANT: Rectifier MUST BE disconnected from stator for this test.

CAUTION

DO NOT use a test instrument with more than a 12 volt source (in the following test),

as rectifier may be damaged.

1. Connect one lead of an ohmmeter (set on R x1 scale) to negative (–) rectifier heat sink

and the other lead to one of the rectifier terminals. Note the reading.

2. Reverse leads and again note reading.

3. Meter should indicate a high or infinite resistance (no meter movement) when

connected one way and a low reading when connected the other. If both readings are

high or infinite, rectifier is open. If both readings are low, rectifier is shorted.

4. Repeat Steps 1. through 3. for two other rectifiers in heat sink.

Index