FUEL INJECTION DESCRIPTIONS AND SYSTEM OPERATION

SERVICE MANUAL NUMBER 24

Page 5D-34

90-861327 OCTOBER 1999

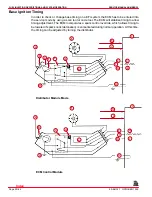

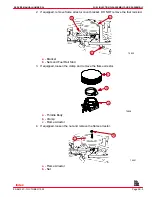

IDLE AIR CONTROL (IAC) VALVE

The purpose of the IAC valve assembly is to control engine idle speed, while preventing

stalls due to changes in engine load. The IAC valve, mounted in the throttle body, controls

bypass air around the throttle valves.

72800

Idle Air Control (IAC) Valve

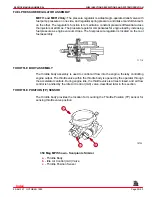

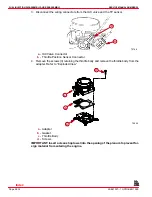

By moving a conical valve known as a pintle, IN, toward the seat (to decrease air flow), or

OUT, away from the seat (to increase air flow), a controlled amount of air moves around the

throttle valve. If rpm is too low, more air is bypassed around the throttle valve to increase

it. If rpm is too high, less air is bypassed around the throttle valve to decrease it.

The ECM moves the IAC valve in small steps, called counts. These can be measured by

scan tool test equipment, which plugs into the DLC connector.

During idle, the proper position of the IAC valve is engine load, and engine rpm. If the rpm

drops below specification and the throttle valve is closed, the ECM senses a near stall condi-

tion and calculates a new valve position to prevent stalling.

•

Engine idle speed is a function of total air flow into the engine based on IAC valve

pintle position.

•

“Controlled” idle speed is programmed into the ECM, which determines the correct

IAC valve pintle position to maintain the desired idle speed for all engine operating

conditions and loads.

•

The minimum idle air rate is set at the factory with stop screws. This setting allows

enough air flow by the throttle valves to cause the IAC valve pintle to be positioned a

calibrated number of steps (counts) from the seat during “controlled” idle operation.

•

If the IAC valve is disconnected and reconnected with the engine running, the idle

speed may be wrong. In this case, the IAC valve can be reset by doing the following:

Turn off engine, wait ten seconds, and restart engine.

72986

IAC Valve Air Flow Diagram

Index