DIAGNOSTICS

SERVICE MANUAL NUMBER 24

90-861327--1 OCTOBER 1999

Page 5G-31

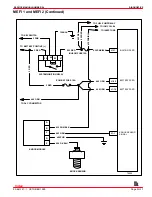

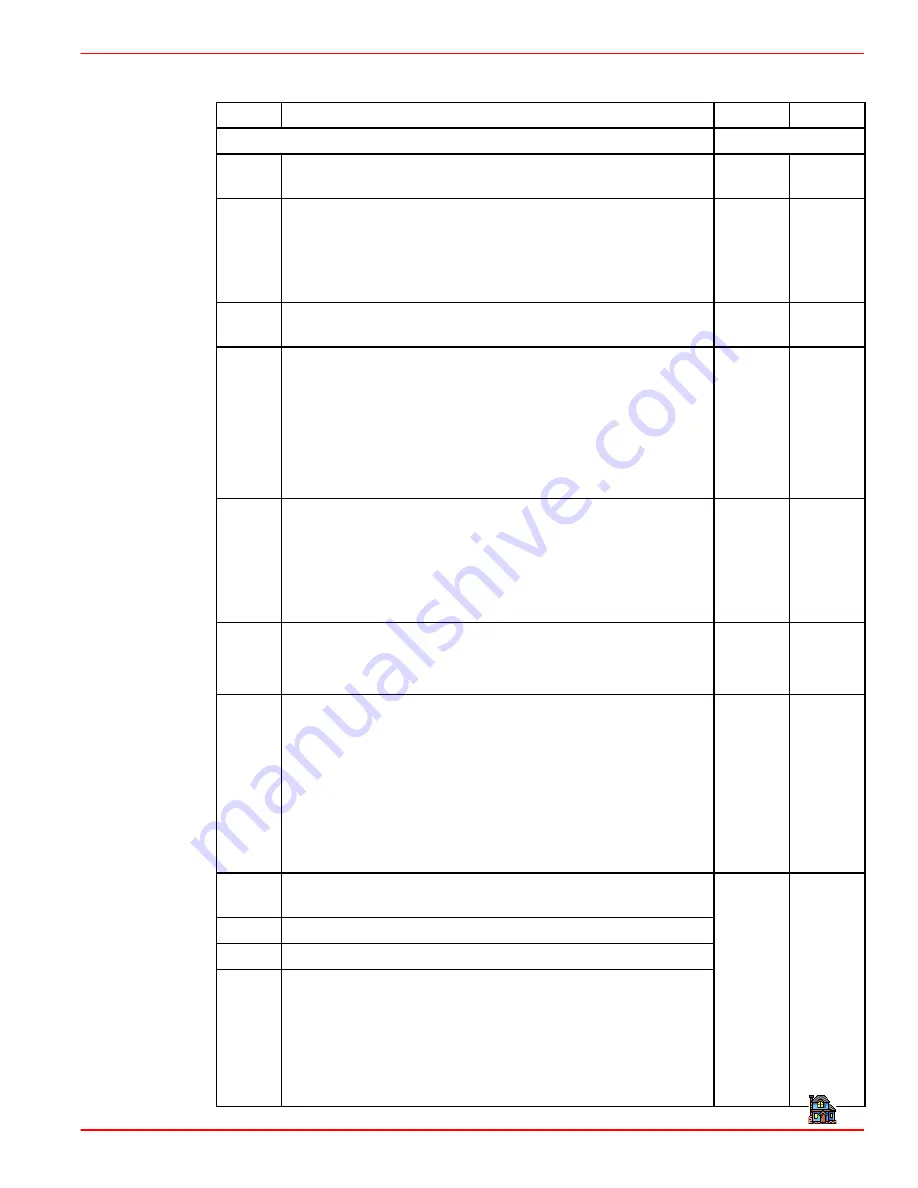

Chart A-3 (2 of 2): Engine Cranks But Will Not Run

Step

Action

Yes

No

PROCEED TO

1.

Was the “On-Board Diagnostic” (OBD) System Check

Performed?

Step 2.

OBD

2.

a. Key OFF for minimum of 10 seconds.

b. Key ON.

c. Listen for fuel pump to run.

Does Fuel Pump Run For 2 Seconds?

Step 3.

Chart

A-5

3.

Check for secondary ignition spark.

Is Adequate Spark Present?

Step 4.

Chart

A-7

4.

a. Install fuel pressure gauge.

b. Ignition OFF for 10 seconds.

c. Ignition ON. Fuel pump will run for about 2 seconds.

d. Note fuel pressure with pump running. The pressure

may drop after the pump stops running.

Is Fuel Pressure Greater Than 25 psi (172 kPa)?

Step 5.

Chart

A-4

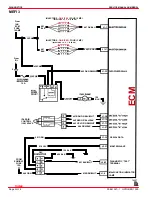

5.

a. Ignition OFF.

b. Disconnect ECM connectors.

c. Measure resistance between ECM CKT 467 and ECM

CKT 468.

Is The Resistance Greater Than 1 ohm?

Step 6.

Step 10.

6.

Check resistance across each injector in the circuit.

MPI: Is Resistance Greater Than 10 ohms?

TBI: Is Resistance Greater Than 1 ohm?

Step 7.

Step 8.

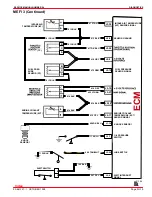

7.

a. Reconnect injectors.

b. Ignition OFF.

c. Disconnect ECM.

d. Ignition ON.

e. Using a test light connected to ground, probe ECM CKT

467 and CKT 468.

Does Test Light Illuminate?

Step 11.

Step 9.

8.

Locate and repair short to ground or replace any injector

that measures low.

9.

Locate and repair open in CKT 467 or CKT 468.

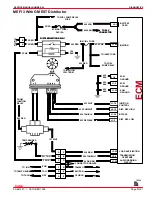

10.

Check for short to ground in CKT 467 or CKT 468.

11.

a. Disconnect all injectors.

b. Ignition ON.

c. Using a test light connected to ground, probe CKT 467

and CKT 468 on the ECM side of the injector harness

(Test one injector harness on each side of the engine).

If light is ON, locate and repair short to voltage.

Verify

Repair

–

Index