DIAGNOSTICS

SERVICE MANUAL NUMBER 24

Page 5G-32

90-861327--1 OCTOBER 1999

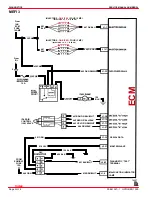

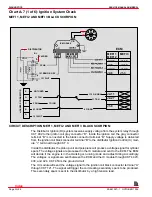

Chart A-4 (1 of 2): Fuel System Diagnosis

75752

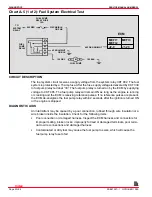

FUEL SHUT-OFF TOOL

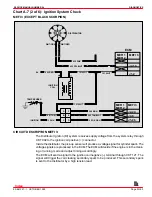

CIRCUIT DESCRIPTION:

When the ignition is turned ON, the Engine Control Module (ECM) will turn the fuel pump

ON for 2 seconds. During engine cranking, the ECM will turn ON the fuel pump. It will remain

ON as long as the engine is cranking or running, and the ECM is receiving ignition reference

pulses. If there are no reference pulses, the ECM will shut OFF the fuel pump.

The pump will deliver fuel to the fuel rail and injectors, then to the pressure regulator, where

the system pressure is controlled to approximately:

TBI Models: 28-32 psi (193-221 kPa)

MPI Models: 34-38 psi (234-262 kPa).

Excess fuel is then returned to the water separating fuel filter.

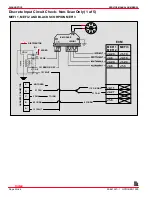

DIAGNOSTIC AIDS:

An intermittent may be caused by a poor connection, rubbed through wire insulation or a

wire broken inside the insulation. Check for the following items:

•

Poor connection or damaged harness. Inspect the ECM harness and connectors for

improper mating, broken locks, improperly formed or damaged terminals, poor termi-

nal to wire connection and damaged harness.

•

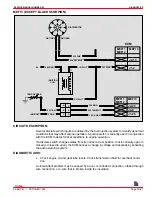

Contaminated or dirty fuel may cause the fuel pump to seize, which will cause the

fuel pump relay fuse to fail.

•

The ability to maintain a constant fuel pressure is very critical in the driveability of

fuel injection. If the fuel pressure drops below the specification of that application,

multiple driveability problems may occur. The vessel may have to be operated under

a load, or certain conditions, as the lack of fuel pressure may be intermittent.

Index