FUEL INJECTION DESCRIPTIONS AND SYSTEM OPERATION

SERVICE MANUAL NUMBER 24

90-861327 OCTOBER 1999

Page 5D-15

ECM FUNCTION

The ECM supplies 5 or 12 volts to power various sensors or switches. This is done through

resistances in the ECM which are so high in value that a test light will not light when con-

nected to the circuit. In some cases, even an ordinary shop voltmeter will not give an accu-

rate reading because its resistance is too low. Therefore, the use of a 10 megohm input

impedance digital voltmeter is required to assure accurate voltage readings.

MEMORY

There are three types of memory storage within the ECM: ROM, RAM and EEPROM.

Read Only Memory (ROM) is a permanent memory that is physically soldered to the circuit

boards within the ECM. The ROM contains the overall control programs. Once the ROM is

programmed, it cannot be changed. The ROM memory is non-erasable, and does not need

power to be retained.

Random Access Memory (RAM) is the microprocessor “scratch pad.” The processor can

write into, or read from, this memory as needed. This memory is erasable and needs a

constant supply of voltage to be retained.

Electronic Erasable Programmable Read Only Memory (EEPROM) is the portion of the

ECM that contains the different engine calibration information that is specific to each marine

application.

Speed Density System

The Electronic Fuel Injection system is a speed and air density system. The system is based

on speed / density fuel management.

Three specific data sensors provide the ECM with the basic information for the fuel manage-

ment portion of its operation. That is, three specific signals to the ECM establish the engine

speed and air density factors.

SPEED

The engine speed signal comes from the distributor’s High Energy Ignition (HEI) module to

the ECM on the distributor reference high circuit. The ECM uses this information to deter-

mine the speed or rpm factor for fuel and ignition management.

DENSITY

The Manifold Absolute Pressure (MAP) sensor is a 3-wire sensor that monitors the changes

in intake manifold pressure which results from changes in engine loads. These pressure

changes are supplied to the ECM in the form of electrical signals.

As intake manifold pressure increases (vacuum decreases), the air density in the intake

manifold also increases, and additional fuel is required.

The MAP sensor sends this pressure information to the ECM, and the ECM increases the

amount of fuel injected by increasing the injector pulse width. As manifold pressure

decreases (vacuum increases), the amount of fuel is decreased.

These two inputs from MAP and rpm are the major determinants of the air/fuel mixture, deliv-

ered by the fuel injection system.

The remaining sensors and switches provide electrical inputs to the ECM which are used

for modification of the air/fuel mixture, as well as for other ECM control functions, such as

Idle Air Control (IAC).

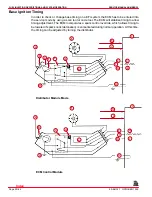

Index