SEAWATER COOLED MODELS

SERVICE MANUAL NUMBER 24

90-861327--1 OCTOBER 1999

Page 6A-19

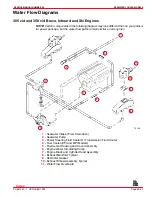

Water Circulating Pump

Removal

1. Drain water from cylinder block.

2. Break loose circulating pump pulley attaching bolts. Do not remove bolts at this time.

3. Loosen alternator tensioner pulley, then pivot alternator inward and remove the serpen-

tine drive belt.

4. Remove pump pulley attaching bolts, lockwashers, clamping ring (if equipped) and

pulley.

5. Disconnect hose(s) from pump.

6. Remove bolts, which secure pump to cylinder block, and remove pump and old gaskets

(discard gaskets).

Cleaning and Inspection

1. Clean gasket surfaces on water pump and cylinder block.

2. Inspect water pump for blockage, cracks, sand holes, corrosion or other damage.

Inspect pump impeller for cracks and erosion. Replace complete pump if any damage

exists.

3. Check impeller shaft and bearings for excessive side play. If play can be felt, replace

complete pump.

4. Inspect pump pulley for bends, cracks, corrosion or other physical damage. Inspect

pulley for rotational trueness. Replace pulley if damaged or untrue.

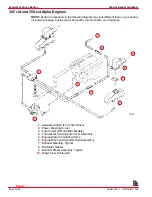

Installation

1. Coat both sides of new circulating pump gasket with Quicksilver Perfect Seal, then posi-

tion gaskets and circulating pump on cylinder block. Coat threads of circulating pump

attaching bolts with Quicksilver Perfect Seal and install bolts and alternator brace (if

applicable). Torque bolts to specifications.

2. Reconnect hoses to pump.

3. Install pump pulley and clamping ring (if used) on pump hub and secure with bolts and

lockwashers. Tighten bolts securely.

4. Install drive belts and adjust tension as outlined in “Drive Belt Tension Adjustment.”

5. Start engine and check for leaks.

Index