90-823224--2 796

454 CID (7.4L) / 502 CID (8.2L) - 3A-25

Hydraulic valve lifters require little attention. Lifters

are extremely simple in design. Normally, readjust-

ments are not necessary and servicing requires only

that care and cleanliness be exercised in the handl-

ing of parts.

Locating Noisy Lifters

Locate a noisy valve lifter by using a piece of garden

hose approximately 4 ft. (1.2 m) in length. Place one

end of hose near end of each intake and exhaust

valve, with other end of hose to the ear. In this man-

ner, sound is localized, making it easy to determine

which lifter is at fault.

Another method is to place a finger on face of valve

spring retainer. If lifter is not functioning properly, a

distinct shock will be felt when valve returns to its

seat.

General types of valve lifter noise are as follows:

1. Hard rapping noise - usually caused by plunger

becoming tight in bore of lifter body so that return

spring cannot push plunger back up to working

position. Probable causes are:

a. Excessive varnish or carbon deposit, causing

abnormal stickiness.

b. Galling or “pickup” between plunger and bore

of lifter body, usually caused by an abrasive

piece of dirt or metal wedged between plung-

er and lifter body.

2. Moderate rapping noise - probable causes are:

a. Excessively high leakdown rate.

b. Leaky check valve seat.

c. Improper adjustment.

3. General noise throughout valve train - this will, in

most cases, be a definite indication of insufficient

oil supply or improper adjustment.

4. Intermittent clicking - probable causes are:

a. A microscopic piece of dirt momentarily

caught between ball seat and check valve

ball.

b. In rare cases, ball itself may be out of round

or have a flat spot.

c. Improper adjustment.

In most cases, where noise exists in one or more lift-

ers, all lifter units should be removed, disassembled,

cleaned in solvent, reassembled and reinstalled in

engine. If dirt, corrosion, carbon, etc., is shown to ex-

ist in one unit, it more likely exists in all the units; thus

it would only be a matter of time before all lifters

caused trouble.

Removal

IMPORTANT: Keep push rod and hydraulic valve

lifter from each valve together as a matched set

and mark them so they can be reinstalled in the

same location later.

Remove as outlined:

1. Remove rocker arm covers.

2. Remove intake manifold.

3. Remove rocker arm assemblies and push rods.

4. Remove valve lifters.

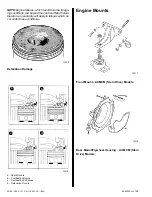

NOTE:Gen VI engines with roller lifters have addi-

tional valve train components shown below.

72329

b

a

a - Lifter Restrictor Retainer

b - Fasteners

72340

b

a

a - Roller Lifter Restrictor

b - Roller Lifter

5. Remove lifter restrictors on roller lifters models.

6. Remove valve lifters.