90-823224--2 796

454 CID (7.4L) / 502 CID (8.2L) - 3A-29

Cylinder Head

Removal

1. Drain engine cooling system.

2. Remove as outlined:

a. Exhaust manifolds.

b. Intake manifold.

c. Rocker arm covers.

d. Rocker arm assemblies and push rods (keep

in order for reassembly in their original loca-

tions).

e. Any components attached to front or rear of

cylinder head.

f.

Spark plugs.

g. Head bolts.

!

CAUTION

The head gasket may be holding cylinder head to

block. Use care when prying off cylinder heads.

DO NOT damage gasket surfaces. DO NOT drop

cylinder heads.

3. Place cylinder head on wooden blocks to prevent

damage to gasket surfaces.

Cleaning and Inspection

1. Clean gasket material and sealer from engine

block and cylinder heads.

2. Inspect sealing surfaces for deep nicks and

scratches.

3. Inspect for corrosion around cooling passages.

4. Clean head bolt threads and engine block bolt

hole threads, making sure no dirt, old oil or cool-

ant remain.

Installation

!

CAUTION

DO NOT use sealer on head gaskets.

1. Place head gasket in position over dowel pins.

2. Carefully set cylinder head in place over dowel

pins.

3. Coat threads of head bolts with Quicksilver Per-

fect Seal and install finger-tight.

4. To insure gasket sealing, torque head bolts in

three steps, following torque sequence for each

step. Start first step at 20 lb. ft. (27 N·m), second

step at 50 lb. ft. (68 N·m), and finish with a final

torque of

7.4L

85 lb. ft. (115 N·m)

454/502 Magnum

92 lb. ft. (124 N·m)

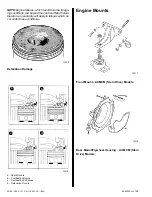

72944

Cylinder Head Torque Sequence

5. Install push rods and rocker arm assemblies in

their original positions. Coat threads on rocker

arm bolt with Perfect Seal. Torque

7.4L

40 lb. ft. (54 N·m)

454/502 Magnum

45 lb. ft. (61 N·m)

6. Install as outlined:

a. Intake manifold.

b. Rocker arm covers.

c. Exhaust manifolds.

d. Spark plugs.

e. Any components removed from front or rear

of cylinder heads.