90-823224--2 796

454 CID (7.4L) / 502 CID (8.2L) - 3A-31

Inspection

1. Inspect cylinder heads for cracks in exhaust

ports, water jackets, and combustion chambers

(especially around spark plug holes and valve

seats). Replace heads if any cracks are found.

2. Inspect cylinder head gasket surface for burrs,

nicks, or erosion or other damage. Also, check

flatness of cylinder head gasket surface, using a

machinist’s straight edge and feeler gauges as

shown. Refer to “Specifications.”

72566

b

a

c

a - Straight Edge

b - Feeler Gauge

c - Take Both Measurements Diagonally Across Head (Both

Ways) And Straight Down Center Of The Head

IMPORTANT: Cylinder head-to-block gasket sur-

face should be resurfaced if warped more than

specified. When head resurfacing is required,

cylinder head-to-intake manifold gasket surface

on head must be milled to provide proper align-

ment between intake manifold and head.

3. Inspect valves for burned heads, cracked faces

or damaged stems.

4. Inspect rocker arm bolts and push rod guides for

wear and damage.

IMPORTANT: Excessive valve stem to bore clear-

ance will cause excessive oil consumption and

possible valve breakage. Insufficient clearance

will result in noisy and sticky valves.

5. Measure valve stem clearance as follows:

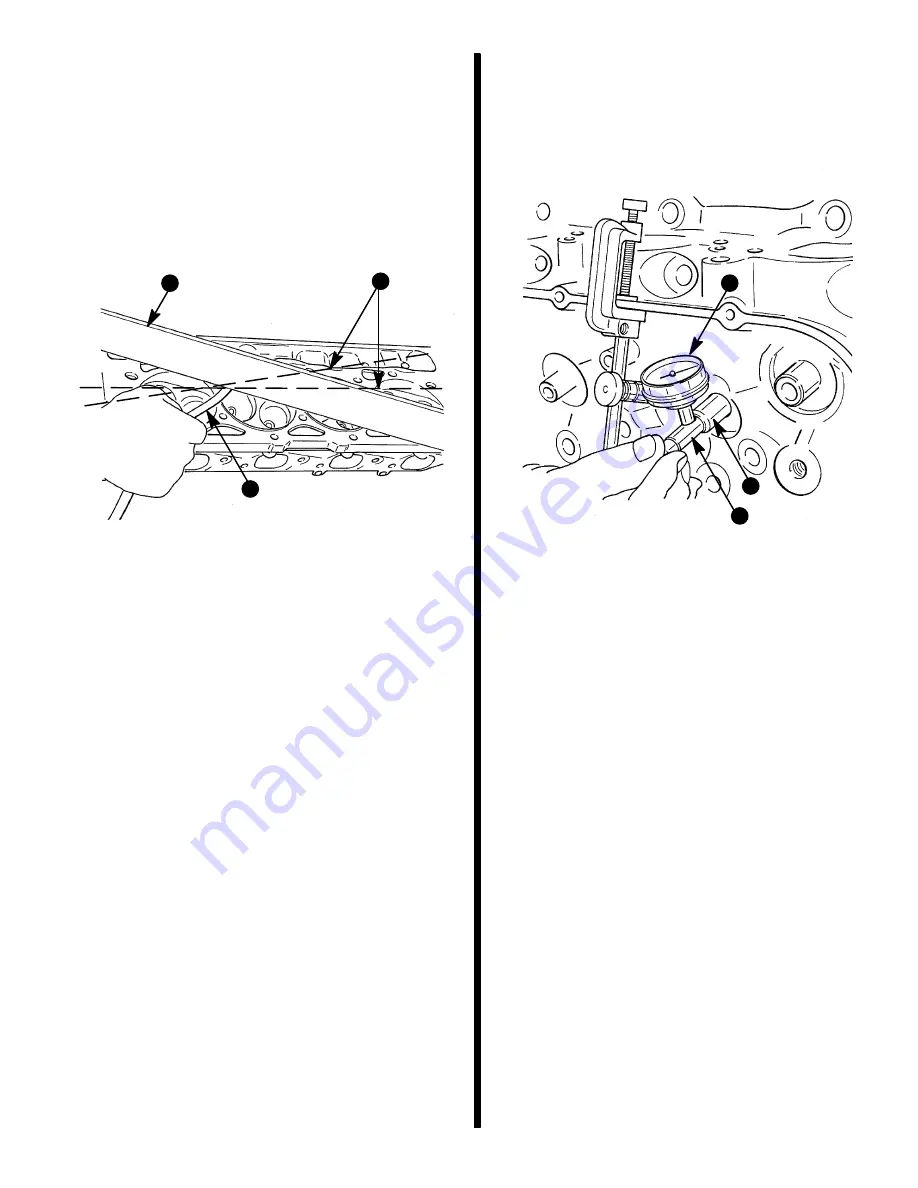

a. Attach a dial indicator to cylinder head, posi-

tioning it against the valve stem and close to

the valve guide.

b. Holding valve head off seat about 1/16 in. (2

mm), move valve stem back and forth in di-

rection shown. Compare stem clearance with

specifications.

72563

b

c

a

a - Valve Stem

b - Dial Indicator

c - Valve Guide

c. If clearance exceeds specifications, it will be

necessary to ream valve guides for oversized

valves, as outlined under “Valve Guide Bore

Repair.”

Valve Guide Bore Repair

IMPORTANT: Be sure to measure valve stem di-

ameter of both the intake and exhaust valve, as

valve stem diameter may or may not be the same

for both valves.

If .015 in. oversize valves are required, ream valve

guide bores for oversize valves, as follows: