90-823224--2 796

454 CID (7.4L) / 502 CID (8.2L) - 3A-33

Valve Grinding

Valves that are pitted must be refaced to the proper

angle. Valve stems which show excessive wear, or

valves that are warped excessively, must be re-

placed. When a valve head which is warped exces-

sively is refaced, a knife edge will be ground on part

or all of the valve head, due to the amount of metal

that must be removed to completely reface. Knife

edges lead to breakage, burning, or pre-ignition due

to heat localizing on this knife edge. If the edge of the

valve head is less than 1/32 in. (0.8 mm) after grind-

ing, replace the valve.

Several different types of equipment are available for

refacing valves. The recommendation of the man-

ufacturer of the equipment being used should be

carefully followed to attain proper results.

50695

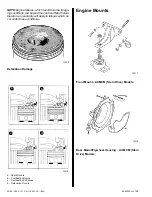

EXHAUST

INTAKE

b

a

b

a

Exhaust

a - 372 In. (9.45 mm)

b - 1/32 [.031] In. (0.79 mm) Min.

Intake

a - 372 In. (9.45 mm)

b - 1/32 [.031] In. (0.79 mm) Min.

Reassembly

1. Lubricate valve guides and valve stems with en-

gine oil.

2. Install each valve in the port from which it was re-

moved or to which it was fitted.

3. Install valve rotators, shims, springs, seals, and

caps as shown under “Valve Assembly (Ex-

ploded View)” for each particular engine.

4. Using valve spring compressor, compress valve

spring and install valve locks (grease may be

used to hold locks in place).

72565

a

a - Valve Spring Compressor (J-8062)