90-823224--2 796

454 CID (7.4L) / 502 CID (8.2L) - 3A-49

8. When all connecting rod bearings have been in-

stalled, tap each rod lightly (parallel to the crank-

pin) to make sure they have clearance.

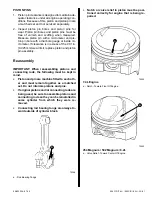

9. Measure all connecting rod side clearances (see

“Specifications”) between connecting rod caps

as shown.

72555

Connecting Rod/Piston

Assembly

Removal

1. Remove as outlined:

a. Oil pan and dipstick tube.

b. Baffle and oil pump.

c. Distributor and intake manifold.

d. Cylinder heads.

2. Use a ridge reamer to remove any ridge and/or

deposits from upper end of cylinder bore.

IMPORTANT: Before ridge and/or deposits are re-

moved, turn crankshaft until piston is at bottom

of stroke and place a cloth on top of piston to col-

lect cuttings. After ridge and/or deposits are re-

moved, turn crankshaft until piston is at top of

stroke, then remove cloth and cuttings.

3. Mark connecting rods and bearing caps (left bank

1, 3, 5 and 7; right bank 2, 4, 6 and 8 from front

to rear on same side as piston thrust).

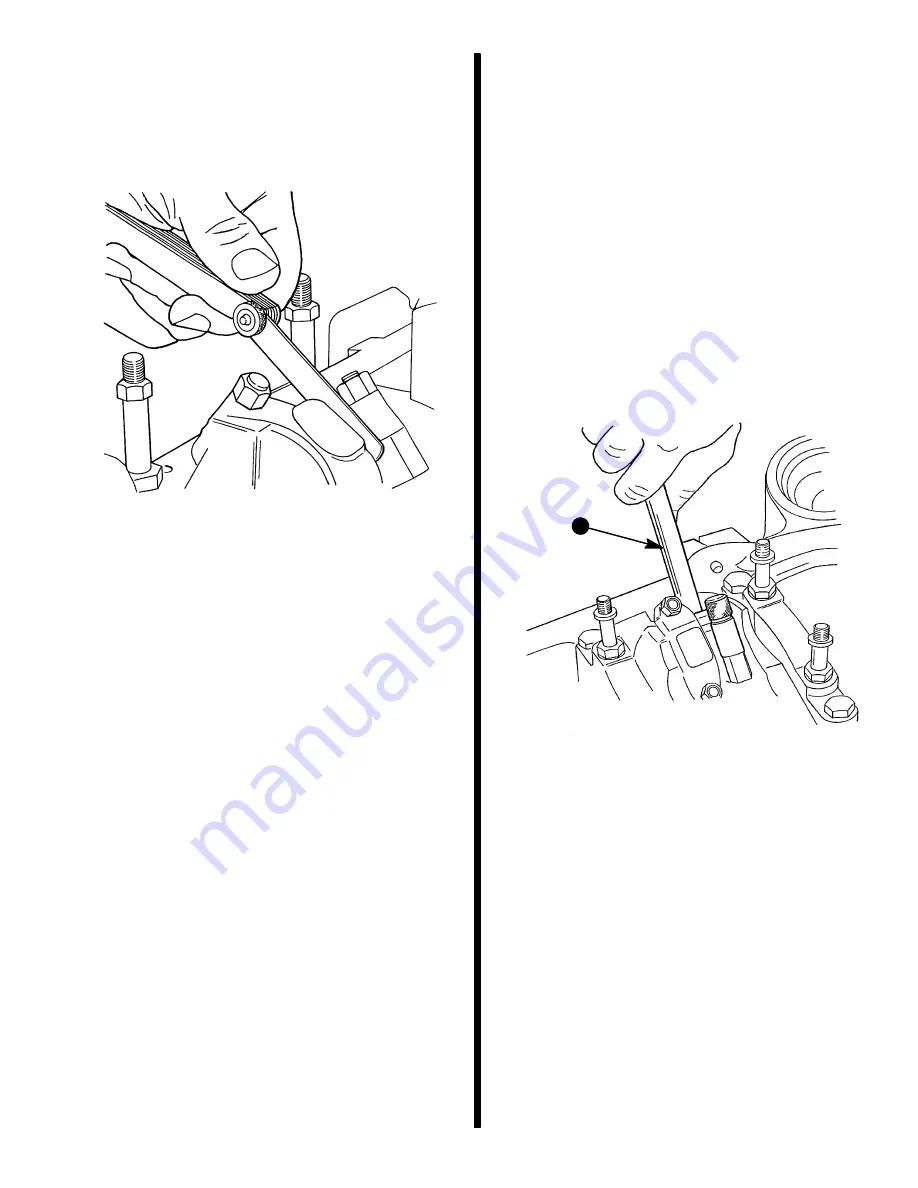

4. Remove connecting rod cap and install connect-

ing rod bolt guide (3/8-24 or 7/16-20) on bolts.

Push connecting rod and piston assembly out of

top of cylinder block.

NOTE:It will be necessary to turn crankshaft slightly

to disconnect and remove some connecting rod and

piston assemblies.

72572

a

a - Connecting Rod Bolt Guide 3/8-24 (J-5239) or 7/16-20

(J-35228)