3A-58 - 454 C.I.D. (7.4L) / 502 C.I.D. (8.2L)

90-823224--2 796

Removal

1. Remove valve lifters as outlined.

2. Remove crankcase front cover as outlined.

3. Remove camshaft as follows:

a. Remove timing chain and sprocket or timing

gears as outlined.

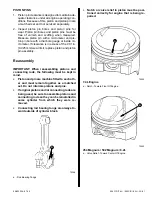

b. Install two 5/16-18 x 5 in. bolts in camshaft

bolt holes and carefully remove camshaft as

shown.

72549

Inspection

Measure camshaft bearing journals with a microme-

ter for out-of-round condition. If journals exceed .001

in. (0.025 mm) out-of-round, camshaft should be re-

placed.

Also check camshaft for alignment with V-blocks and

dial indicator which indicates exact amount camshaft

is out of true. If out more than .002 in. (0.051 mm)

(dial indicator reading) camshaft should be replaced.

72382

Checking Camshaft Alignment

Installation

1. Install camshaft as follows:

a. Install two 5/16-18 x 5 in. bolts in camshaft

bolt holes, then lubricate camshaft journals

with engine oil and install camshaft, being

careful not to damage bearings.

b. Lubricate camshaft lobes with General Mo-

tors Cam and Lifter Prelube or equivalent.

c. Install timing chain or gears as outlined.

2. Install crankcase front cover and valve lifters as

outlined.

Camshaft Bearings

Removal

Camshaft bearings can be replaced while engine is

disassembled for overhaul or without complete dis-

assembly. To replace bearings without complete dis-

assembly, remove camshaft and crankshaft, leaving

cylinder heads attached and pistons in place. Before

removing crankshaft, fasten connecting rods against

sides of engine so that they will not interfere while re-

placing camshaft bearings.

1. With camshaft and crankshaft removed, drive

camshaft rear plug from cylinder block.

NOTE:This procedure is based on removal of bear-

ings from center of engine first, thus requiring a mini-

mum amount of turns to remove all bearings.