Section 5 - Maintenance

Page 78

90-8M0070851

eng

AUGUST 2012

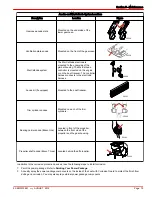

Sterndrive Corrosion Protection Components

To help control the effects of galvanic corrosion, Mercury Diesel sterndrives come with several sacrificial anodes and other

corrosion protection devices. For a more comprehensive explanation of corrosion and corrosion protection, refer to the

Marine

Corrosion Protection Guide

(90‑88181301).

1 -

Gearcase anodic plate

2 -

Anode plate

3 -

MerCathode system

4 -

Anode kit

5 -

Trim cylinder anodes

6 -

Bearing carrier anodes

7 -

Propeller shaft anode (Bravo III standard)

NOTICE

Washing the MerCathode assembly can damage components and lead to rapid corrosion. Do not use any cleaning

equipment such as brushes or high‑pressure washers to clean the MerCathode assembly.

Do not pressure wash the MerCathode assembly. Doing so will damage the coating on the reference electrode wire and

decrease the corrosion protection.

MerCathode—mounted to the underside

of the gimbal housing

a -

MerCathode reference electrode

b -

Do not paint

c -

Do not pressure wash

Anodes and MerCathode System Locations

IMPORTANT: Replace sacrificial anodes if eroded 50 percent or more.

The following sacrificial anodes are installed at different locations on your power package. These anodes help protect against

galvanic corrosion by sacrificing their metal to be slowly eroded instead of the metal components on the power package.

MerCathode system—

The electrode assembly replaces the anode block. The system should be tested to ensure adequate

output. The test should be performed where the boat is moored, using a Quicksilver Reference Electrode and Test Meter.

Contact your Mercury Diesel authorized repair facility.

20337

5

1

7

2

3

4

6

6211

c

b

a